Cosmetic filling machines: Processing perfume, cream, lipgloss, mascara and more

As a company, we understand the importance of providing safe and efficient production processes for our clients in the cosmetics industry. With our focus on system development and construction, we have become one of the leading suppliers of automatic liquid cosmetic filling machines. Our commitment to environmental protection means that we plan and execute every process step in a sustainable and resource-saving manner, ensuring that our production lines are not only efficient but also eco-friendly.

Our passion for automatic filling machines drives us to provide our clients with the best stuff possible for filling various kinds of liquid cosmetics, including mascara, lip gloss, perfume, and cream. We understand that each application requires a unique approach, which is why we offer a proven line portfolio that maximizes process reliability while minimizing risks.

It is our combination of technological innovation and exemplary service that sets us apart from other suppliers. We believe that our products, equipment, and systems are truly unique and capable of delivering excellent results for our clients in the cosmetics industry. Our focus on safe and stable system development and construction ensures that our clients can rely on us for stable production processes and efficient results every time.

Process steps of our cosmetic filling machines

Stockpiling and feeding

We always plan the stockpiling and feeding of items with our customers within the framework of an individual concept that is tailored to the type of bottles as well as to the way in which the items are delivered.

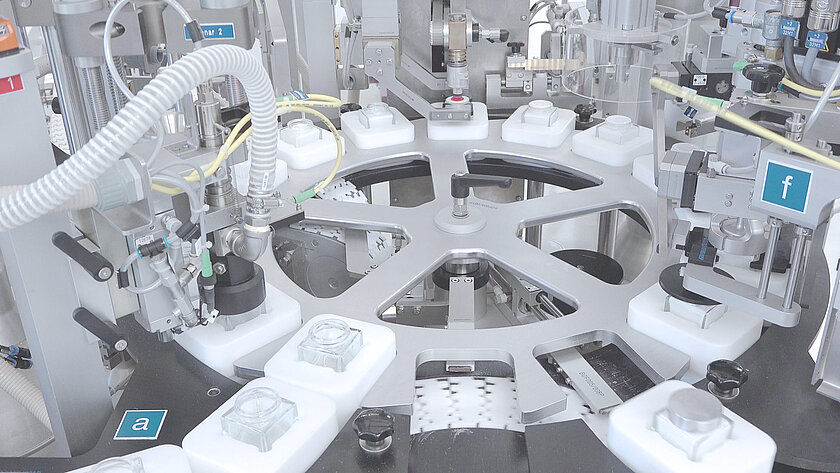

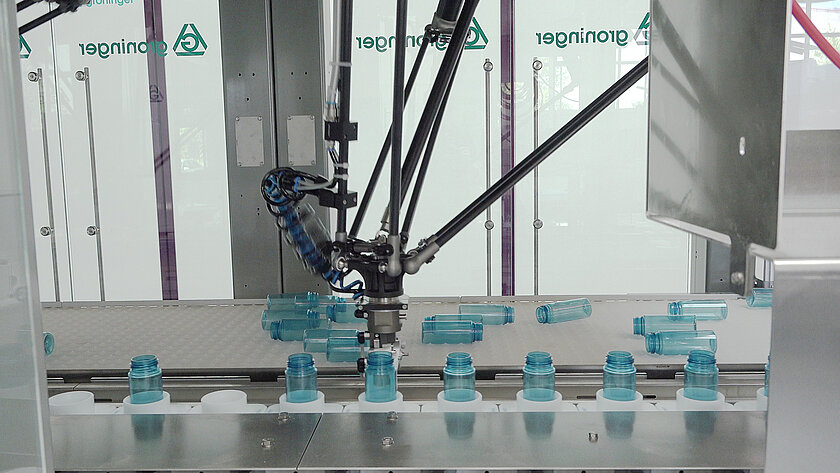

In this area we use, for example, hopper conveyors, dosing elevators, plate conveyors or disc sorters. In our systems, these technologies are increasingly being replaced by robot applications, which we have been using and developing for many years.

Bottles, closures and other packaging components are then fed in as bulk goods or by means of trays (also reusable systems); the robot places the items in transport pucks, transport systems or directly in a downstream machine in an extremely product-friendly manner.

Filling and cleaning

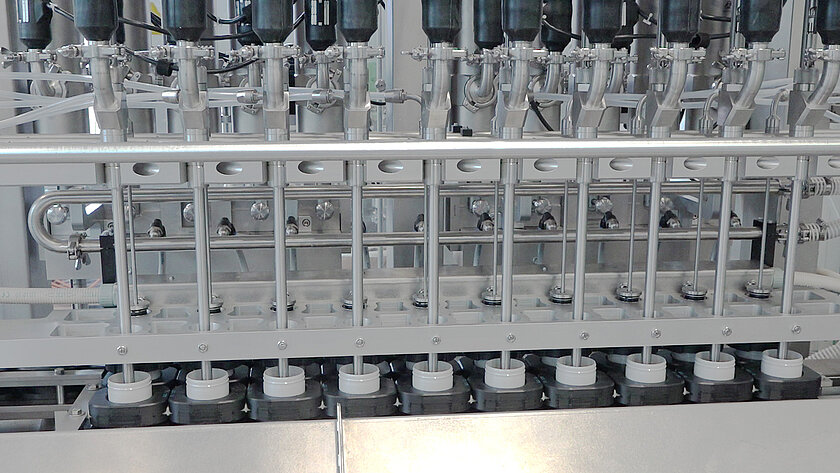

Our cosmetic filling equipment is versatile and can cater to a wide range of needs in the cosmetic industry. Whether you need to fill small or large quantities of products with varying viscosities, our equipment can handle it all. With a range of options available from semi-automatic small fillers to fully-automatic high-capacity fillers, you can choose the one that best suits your requirements. Our filling solutions are available in different shapes and sizes, and they can process various cosmetics such as perfume, cream, lipgloss, mascara, and many more.

One of the most significant advantages of our equipment is the variety of filling systems we use. We employ rotary piston pumps, linear piston pumps, and mass flow meters to ensure that we can fill low to high-viscosity products as required. Regardless of the filling volume, we can guarantees maximum process reliability.

We understand that cleaning is an essential aspect of any filling process. Our machines can be cleaned using various methods such as cold cleaning, hot cleaning, sanitizing, or sterilization with CIP/SIP. Additionally, manual cleaning is possible without any problems thanks to our pump change trolley. The filling system can be easily removed from the line, making it easy to clean.

We also ensures that filling and cleaning can take place simultaneously, saving you valuable time. Using redundant filling systems, we can achieve maximum efficiency. Our cosmetic filling equipment is perfect for any cosmetic manufacturer looking to improve their filling process.

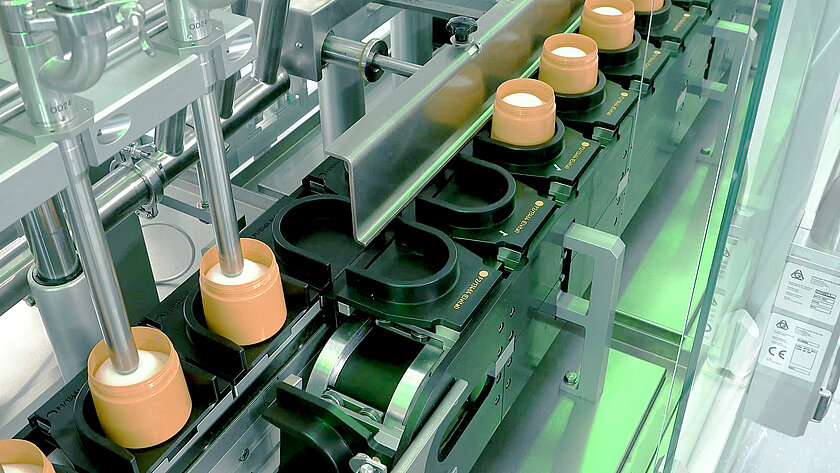

Closing

Gentle pressing and exact screwing with a large number of different closures: This is how we are able to guarantee you the highest quality with our automatic closing machines. We distinguish between two types of closing:

- Intermittent capping machines are suitable for press-on and screw caps, spray and dispenser pumps as well as for multi-part closures.

- High-performance capping machines for round, flat and shaped bottles run continuously and offer the possibility to process different closures.

Thanks to the latest servo drives, the intermittent modules can be used flexibly on the basic machine and can also be combined with one another. They offer different screwing modes (torque, stop and angle) and rely on careful container closing.

The servomotors, an exact and reproducible torque can be guaranteed during screwing; with all movements it is ensured that future formats can also be set up and run on the machine without any problems.

Transport

Suitable for your product: Depending on the line, we offer either continuous or intermittent item transport--or a combination of both.

We prefer to use walking beams with a hygienic design for the filling and closing machine. On the conveyor belts, gentle movements are definitely ensured for smooth passage.

We also offer the option of transporting items that are not stable and cannot be stowed in the transport puck, should this be necessary for your purposes. Through the use of intelligent transport systems with freely programmable transport carriers, we also increase the flexibility of our processing lines.

Labeling and marking

Labeling and marking can also be integrated on our groninger equipment. The packaging containers are guided precisely to the labeling station via the precise star guide and are labeled exactly by the massaging belt. As a result, a completely finished product is yielded at the end of the process. Strip end and strip tear-off monitoring is part of the process reliability.

Depending on the need and application, the printers that are suitable for the label can be used; thermal transfer printers and laser printers are generally the standard.

To ensure reliable control of labeling and marking, we rely on the use of vision systems to provide an optimal result.

With their compact design, our labelers can also be used in confined spaces, integrated as a stand-alone machine or permanently into the line.

Innovative processes for future challenges

Our research and development are the basis for new perspectives. We want to develop and implement an optimal concept individually based on your needs; to achieve that we work closely with all our customers and suppliers.

By joining project management and service together, we ensure that we are able to achieve excellent results together with you - even at short notice. This also includes the extensive documentation and validation of our lines.

Now, we also offer some digital services such as automation, improved analyses or personalization. Talk to us!

Body and hair care products, creams and makeup, perfume and fragrance, color care and nail polish

At groninger, we understand that every cosmetics manufacturer has unique needs and challenges when it comes to their production. That's why we provide excellent product management and service to ensure that you receive the perfect groninger filler for your specific requirements. From planning to long after line commissioning, we're with you every step of the way to ensure that your filler operates with maximum efficiency for your product variety.

Our commitment to the latest technological standards is evident in every aspect of our design, from GMP-compliant practices to hygienic designs for sensitive areas of the machine. We believe that documentation and validation are key components of a successful production, and we make sure to include them in our processes.

As experts for cosmetic filling machines, we are dedicated to creating innovative machine concepts that meet the evolving needs of the future. We are constantly refining our current solutions and developing new ones for a range of products, including shampoo, body lotion, mascara, perfume, and makeup. Our primary objective is to ensure that each product is processed with the ideal technology that meets its unique requirements.

We utilize state-of-the-art servomotor drives for all line movements, ensuring that all processes are carried out safely, effectively, and with precision. We provide testing stations for weighing, torque checking, and camera systems for visual inspection, which allows us to guarantee optimum quality assurance. With Groninger, you can be confident that your customers will always receive impeccable products that meet their expectations.

FRAGRANCE with an output of up to 80 objects per minute

We also process unusual bottle designs flexibly and independently of the format. We offer maximum process reliability with precise control of the filling process for foaming products, perfume, aftershave and eau de toilette - for small and large production batches. With extensive experience under our belt, we have developed a wealth of knowledge and expertise to meet even the most challenging requirements with a profitable technology. Our service is also unbeatable beyond the installation. Thanks to a fast response time, you don’t have to wait long for new format parts, as a result you are able to act very flexibly.

Highlights

- Level filling

- Fast inline cleaning

- Compensation of bottle tolerances during crimping

SKIN CARE with an output of up to 150 units per minute

We guarantee reliable and precise filling results and safe sealing of jars and small bottles made of glass and plastic. With various machine and line concepts, we respond individually to your needs and are able to offer a wide range of services. For example, we can easily fill jars with a diameter of 100 mm with liquid, viscous or highly viscous products.

Highlights

- Spinning during the filling process

- Heat sealing of aluminum foils

- Servo-controlled pre and post-screwing with left/right screwing

COLOR CARE with an output of up to 240 units per minute

Mascara, lip gloss and eyeliner up to 240 units per minute

With maximum process reliability and precise control, we exceed our customers’ expectations. Our excellent closure technology also works with unstable and conical packaging containers. The specially manufactured, wear-free and extremely compact rotary piston pump developed by groninger ensures quick and particularly easy manual cleaning.

Highlights

- Hot filling lip gloss

- Processing high viscosity products

- 100% in-process weight monitoring

Make-up up to 120 units per minute

High flexibility and full control - with our process solutions we will meet all your requirements when filling makeup bottles. Based on many years of experience in handling sensitive and high-quality items, our concepts will guarantee you careful processing without damage and contamination, as well as minimal product loss and the shortest changeover times.

Highlights

- Up to three closure components

- 100% in-process weight control

- Laser marking

Nail polish up to 120 units per minute

Outstanding machine concepts with a high level of safety and minimal product loss are our claim when processing bottles with screw-on brushes. From the compact star machine with manual item feed to the highly automated, multi-position intermittent linear machine, our portfolio offers technologies for all your requirements in the field of nail polish processing.

Highlights

- Up to three closure components

- Filling glitter products

- Tested ATEX version possible

BODY & HAIR CARE with an output of up to 240 units per minute

We fill liquid soap, body and hair care products (e.g. shampoo) flexibly and individually tailored to the product and item. Our goal is maximum end product quality. Simple and tool-free format changes, redundant filling systems and format part-free feeds are just a small part of our solutions to provide you with the highest system availability.

Highlights

- Very high filling volumes possible (up to 1 liter)

- Product change within minutes

- Filling two-phase products

Robot sorting and feeding

With our comprehensive consulting know-how and our experience, we are able to advise and support you on all matters relating to the field of cosmetic filling. We also provide you with comprehensive knowledge in the field of robotics based on a large number of implemented projects. This is how we offer you the best possible processes for your requirements.

Highlights

- Depalletizing trays from the pallet(s)

- Processing trays and boxes with compartments

- Sorting items from bulk material

- Can be user for glass and plastic items

- Handling robots: blowing out overhead,

- positioning bottles and assembly work

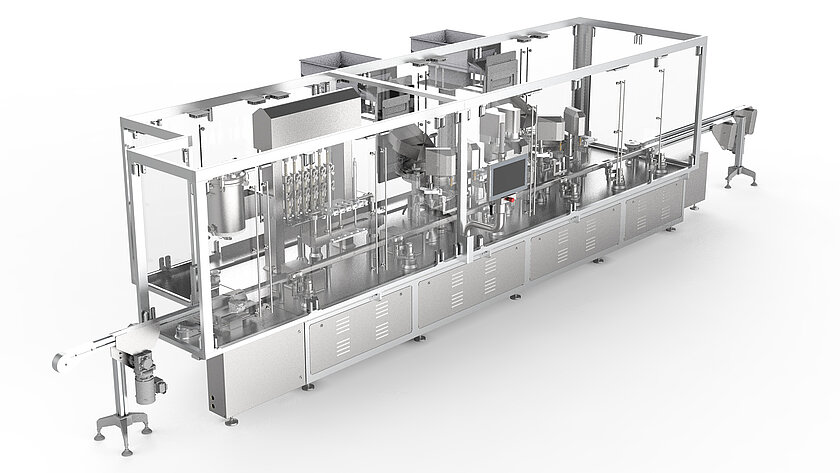

Our selected comprehensive solutions for the cosmetics industry

We have carefully curated a range of comprehensive answers to meet your needs in the cosmetics industry. The highlight: A large number of options in terms of equipment and use give you a great deal of design freedom - so you can act flexibly, quickly and in a future-oriented manner. Our entire know-how is in these lines.

Our ready engineered philosophy enables short delivery times instead of time-consuming planning and construction phases. Reliability for your production planning and for the products to be processed - from scented fragrance to hair care products, from nail polish to mascara.

We considered all challenges. This way you can start faster.

fragrance 50

The innovative perfume filling machine also for aftershave and eau de toilette.