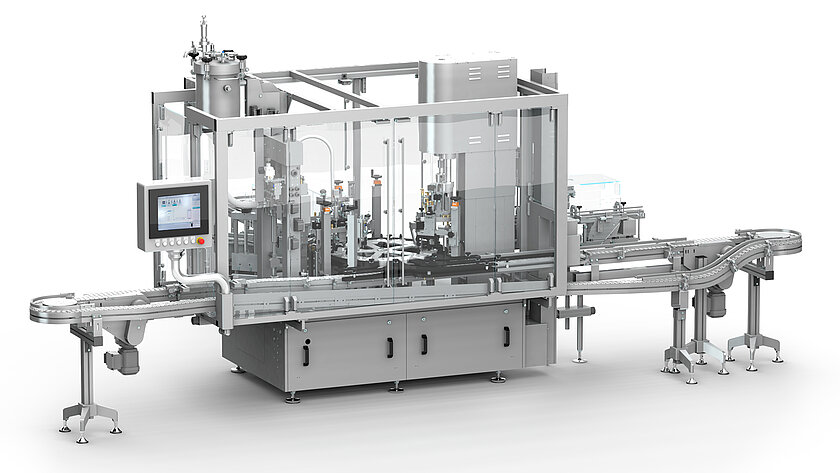

![[Translate to English:] COLOR 60 [Translate to English:] groninger COLOR 60](/fileadmin/content/03_Kosmetik/02_Produkte_und_Anlagen/Color/groninger-color-60-total-sw.jpg)

Mascare, Eyliner, Make-up and Lip gloss filling machine

color 60 is a highlight from the groninger ready engineered series. This automatic filling machine processes liquid cosmetics products like mascara, lip gloss, eyeliner, brow filler, makeup sticks and dispenser bottles at up to 60 units per minute.

We, as one of the leading international manufacturers of filling machines, offer full flexibility: When configuring the color 60, you can rely on the full equipment right from the start, which leaves nothing to be desired with comprehensive production options. Or you can simply and easily integrate additional technical features later and as required. Or rely on the full equipment right from the start.

The groninger ready engineered concept will provide you with the highest product quality that matches your needs exactly, while ensuring short delivery times. The solution can be configured to suit your individual needs with little effort. And our service is there to provide you with immediate solutions when it matters most.

color 60 highlights

-

Different filling systems

Each product has certain requirements that must be observed during filling. Viscosity and filling temperature are only two factors. Different filling systems will prepare you for every eventuality. It is possible to fill at higher temperatures, for example, for creamy liquids a rotary piston pump is used. In order to prevent air bubbles, the item can be rotated on a centrifuge station in a controlled manner.

-

Different closing stations

With the color 60 you also have the option of using different closing stations, so that the right lid is used for every item. Wipers and stoppers on station 1, brush caps, screw or snap-on caps on station 2 - that's no problem with our line.

-

Star transport for all puck sizes

If different products have to be transported again and again, using puck transport saves money. This way a format change is easy because only the transport pucks have to be changed.

-

Space for special functions

The color 60 is designed in such a way that various special functions or even manual work steps can be carried out on a separate conveyor loop without any problems.

-

Siemens or Rockwell control

The machines can be controlled with Siemens or Rockwell.

color 60 advantages

- High machine availability and productivity

- Highest process reliability with precise filling process control

- Format-independent: Processing a wide range of products to be filled

- Cosmetics can also be filled at a controlled temperature - Lip gloss filling machines for hot filling

- Different pump sizes can be combined and independently controlled

- Secure closure technology, even with unstable and conical containers

- Easy to maintain and easy to upgrade, for example, simple and ergonomic replacement of product tanks and pumps

- Use of high-quality and stable materials

- Safer than the required standards

- Maximum quality of the final product