Füllen und Verschließen von Cremes, Mascara, Lipgloss, Make-up, Eyeliner und noch mehr

Unser Denken und Handeln wird davon bestimmt, Fertigungsabläufe sicher, effizient und zukunftsorientiert zu gestalten. Durch sichere und stabile Anlagen-Entwicklung und Anlagen-Konstruktion garantieren wir unseren Kunden stabile Produktionsprozesse und exzellente Ergebnisse. Und wir haben den Umweltschutz im Blick: Jede Anlage, jeder Prozessschritt wird nachhaltig und ressourcenschonend geplant und ausgeführt.

Die Verbindung von technologischer Innovation und vorbildlichem Service macht unsere Maschinen, Anlagen und Systeme einzigartig. Unser bewährtes Anlagenportfolio ermöglicht für jede Anwendung höchste Prozesssicherheit durch größtmögliche Risikominimierung.

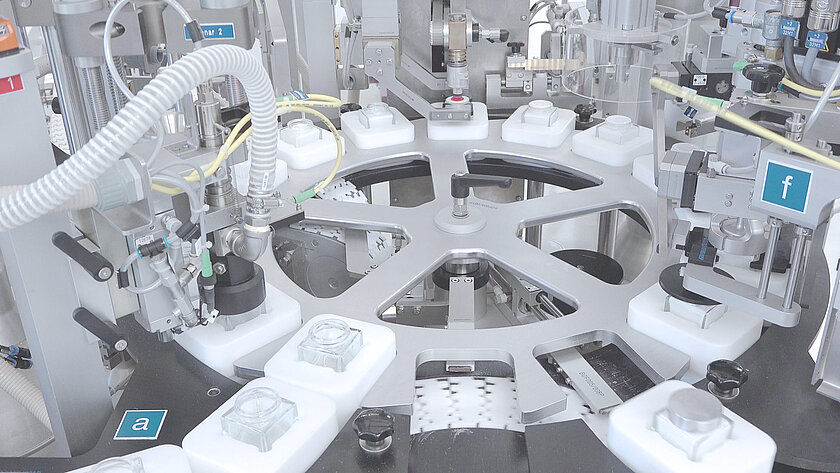

Bevorraten und Zuführen

Die Bevorratung und Zuführung der Objekte planen wir mit unseren Kunden stets im Rahmen einer individuellen Konzeption, die auf die Art des Gebindes ebenso abgestimmt ist wie auf die Art, wie die Objekte angeliefert werden.

In diesem Bereich verwenden wir zum Beispiel Bunkerbänder, Dosierelevatoren, Plattenförderer oder Scheibensortierer. In unseren Anlagen werden diese Technologien zunehmend durch Roboter-Applikationen abgelöst, die wir bereits seit vielen Jahren einsetzen und weiterentwickeln.

Flaschen, Verschlüsse und andere Verpackungskomponenten werden dann als Schüttgut oder mittels Trays (auch Mehrwegsysteme) zugeführt; der Roboter setzt die Objekte äußerst produktschonend in Transportbecher, Transportsysteme oder direkt in eine Folgemaschine ein.

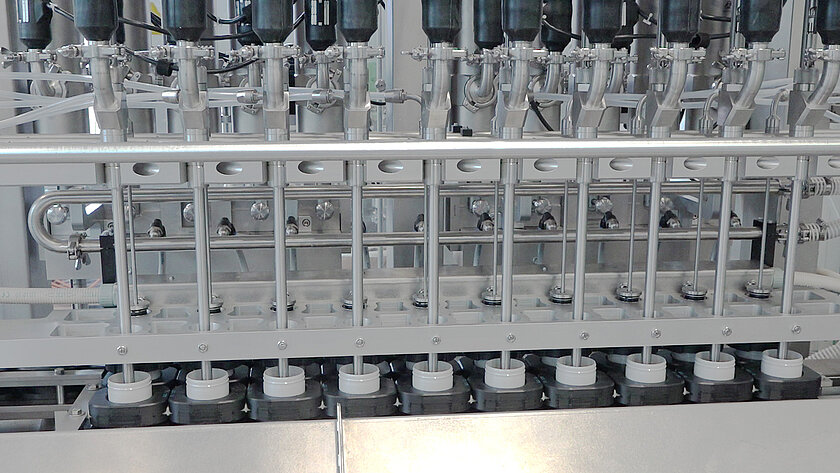

Füllen und Reinigen

groninger Füllmaschinen sind vielfältig einsetzbar: für kleine und große Mengen, für Produkte von ganz unterschiedlicher Viskosität.

Unsere Anlagen überzeugen als halbautomatische Kleinfüller genauso wie als vollautomatische Hochleistungsmaschinen mit unterschiedlichen Formen und Größen. Wir setzen verschiedenste Füllsysteme ein: Rotationskolbenpumpe, Linearkolbenpumpe und Massedurchflussmesssysteme. So lassen sich je nach Bedarf niedrig- bis hochviskose Produkte abfüllen. Zugleich garantieren wir höchste Prozesssicherheit bei kleinen und bei großen Füllvolumina.

Die Füllsysteme unserer Anlagen können je nach Bedarf mit der benötigten Methode gereinigt werden, ob Kaltreinigung, Heißreinigung, Sanitisieren oder Sterilisation mit CIP/SIP. Durch einen Pumpenwechselwagen wird manuelles Reinigen problemlos möglich: Er ermöglicht es, dass das Füllsystem einfach aus der Anlage entfernt und gereinigt werden kann.

Wir ermöglichen auch, dass Füllen und Reinigen auf der Anlage synchron stattfinden. Redundante Füllsysteme machen es möglich, die höchstmögliche Anlageneffizienz zu erreichen.

Verschließen

Schonendes Aufdrücken und exaktes Verschrauben bei einer Vielzahl von unterschiedlichen Verschlüssen: So garantieren wir Ihnen bei unseren Verschließmaschinen höchste Qualität.

Wir unterscheiden zwischen zwei Arten von Verschließmaschinen:

- Getaktet laufende Verschließmaschinen sind zur Verarbeitung von Aufsetz- und Schraubkappen, Sprüh- und Dispenserpumpen sowie für mehrteilige Verschlüsse geeignet.

- Hochleistungsverschließmaschinen für Rund-, Flach-, und Formflaschen laufen kontinuierlich und bieten die Möglichkeit, verschiedene Verschlüsse zu verarbeiten.

Dank modernster Servoantriebe sind die getakteten Module auf der Grundmaschine flexibel einsetzbar und können miteinander kombiniert werden. Sie bieten verschiedene Verschraubmodi (Drehmoment, Anschlag und Winkel) und setzen auf gebindeschonendes Verschließen.

Durch die Nutzung der Servomotoren kann beim Verschrauben ein exaktes und reproduzierbares Drehmoment garantiert werden; bei allen Bewegungen ist sichergestellt, dass auch künftige Formate auf der Maschine problemlos eingerichtet und gefahren werden können.

Transportieren

Passend zu Ihrem Produkt: Je nach Anlage bieten wir einen kontinuierlichen oder einen getakteten Transport der Objekte an – oder eine Kombination aus beiden Techniken.

In der Füll- und Verschließmaschine kommt vorzugsweise ein Transportrechen mit hygienischem Design zum Einsatz. Auf den Transportbändern ist eine schonende Bewegung für einen reibungslosen Durchgang selbstverständlich.

Unsere Anlagen bieten zudem die Möglichkeit, nicht standfeste und nicht staufähige Objekte im Transportbecher zu transportieren, wenn dies für Ihre Zwecke notwendig ist. Durch den Einsatz von intelligenten Transportsystemen mit frei programmierbaren Transportträger erhöhen wir zusätzlich die Flexibilität unserer Verarbeitungslinien.

Etikettieren und Markieren

Die Integration der Etikettierung und Markierung ist auf unseren groninger Maschinen ebenfalls möglich. Über die präzise Sternführung werden die Behältnisse genau zur Etikettierstation geführt und vom Massierband exakt etikettiert. So steht am Ende des Prozesses ein rundum fertiges Produkt. Eine Bandend- und Bandabrisskontrolle gehört zur Prozesssicherheit dazu.

Je nach Bedarf und Anwendungsfall können die für die Etikette geeigneten Drucker eingesetzt werden; Thermotransferdrucker und Laserdrucker gehören zu den Standards.

Zur zuverlässigen Kontrolle von Etikettierung und Markierung setzen wir für ein optimales Ergebnis auf den Einsatz von Vision-Systemen.

Mit ihrer kompakten Bauweise finden unsere Etikettierer auch in beengten Raumverhältnissen Platz, ob als Einzelmaschine oder fest in die Linie integriert.

Innovative Prozesse für zukünftige Herausforderungen

Unsere Forschung und Entwicklung sind die Basis für neue Perspektiven. Wir wollen individuell nach Ihren Bedürfnissen ein optimales Konzept entwickeln und umsetzen; dafür arbeiten wir eng mit all unseren Kunden und Lieferanten zusammen.

Durch die Verzahnung von Projektmanagement und Service sorgen wir dafür, dass wir gemeinsam mit Ihnen auch kurzfristig zu exzellenten Ergebnissen kommen. Die umfangreiche Dokumentation und Validierung unserer Anlagen gehört selbstverständlich auch dazu.

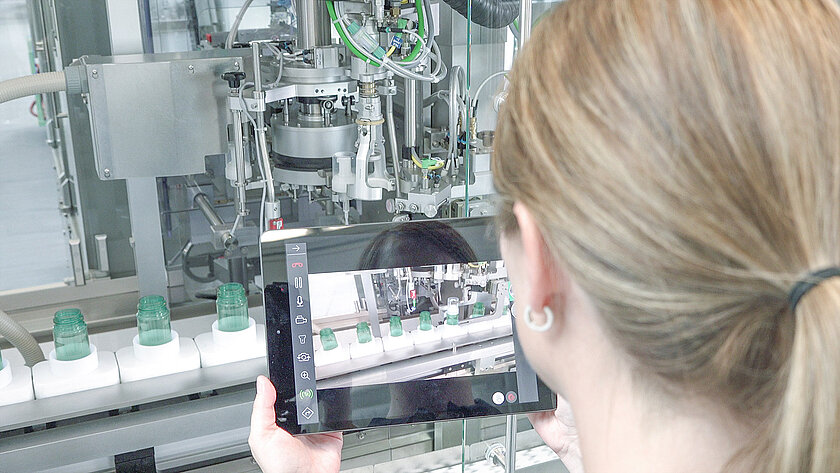

Zusätzlich bieten wir inzwischen einige digitale Services wie Automatisierung, verbesserte Analysen oder Personalisierung an. Sprechen Sie uns an!

Körper- und Haarpflegeprodukte, Cremes und Make Up, Parfum und Duftwasser, Color Care und Nagellack mit unseren kundenorientierten und flexiblen Lösungen

Immer die passende Lösung, immer der passende Prozess: Mit exzellentem Produktmanagement und ausgezeichnetem Service von der Planung bis lange über die Inbetriebnahme einer Maschine hinaus sorgen wir dafür, dass Sie von groninger genau die Anlage erhalten, die für Ihre Zwecke und Herausforderungen die richtige ist: für Ihre Produktvielfalt die gewünschte Effizienz.

Neueste Standards im Bereich der Technologie gehören für uns ebenso zu einer GMP-gerechten Ausführung dazu wie hygienisches Design an den sensiblen Bereichen der Anlage. Dokumentation und Validierung sind ein fester Bestandteil davon.

Gerade im Bereich der Kosmetik-Anlagen erarbeiten wir kreative Maschinenkonzepte für die Anforderungen der Zukunft. Kontinuierliche Verbesserung des Bestehenden gehört selbstverständlich auch dazu. Ob Shampoo, Body Lotion, Mascara, Parfum oder Make-Up – wir kreieren immer die richtige Lösung für alle zu verarbeitenden Produkte.

Durch servomotorische Antriebe für alle Bewegungen der Linie können alle Prozesse sicher, effektiv und präzise durchgeführt werden. Für die optimale Qualitätssicherung sorgen Prüfstationen zum Wiegen, zur Drehmomentüberprüfung oder Kamerasysteme zur visuellen Kontrolle. So können Sie sicher sein, dass Ihre Kunden stets einwandfreie Produkte erhalten.

FRAGRANCE mit Leistung bis zu 80 Objekte pro Minute

Flexibel und formatunabhängig verarbeiten wir auch ausgefallene Flakon-Designs. Wir bieten höchste Prozesssicherheit mit exakter Steuerung des Füllprozesses von schäumenden Produkten, Parfum, After Shave und Eau de Toilette - für kleine und große Produktionschargen. Durch unsere jahrelange Erfahrung haben wir umfangreiches Know-how aufgebaut und bieten auch für anspruchsvolle Anforderungen eine gewinnbringende Lösung. Darüber hinaus ist unser Service auch über die Installation hinaus unschlagbar. Durch eine schnelle Reaktionszeit müssen Sie nicht lange auf neue Formatteile warten und können somit sehr flexibel agieren.

Highlights

- Niveaufüllen

- Schnelle Inline-Reinigung

- Kompensation der Flaschentoleranzen beim Crimpen

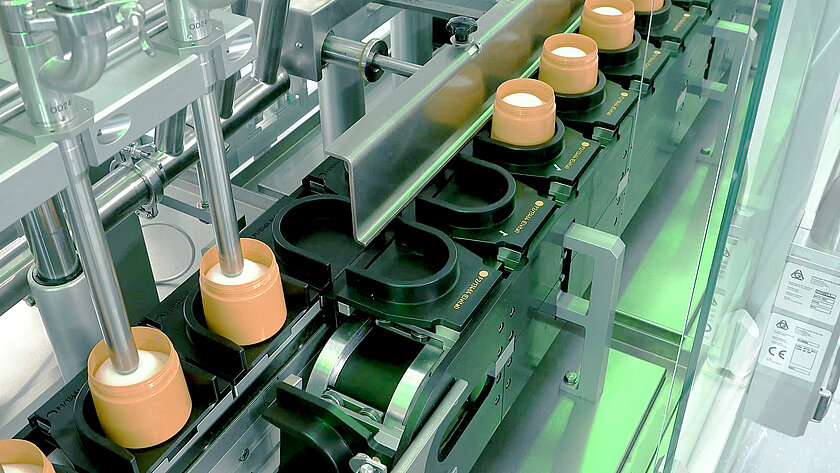

SKIN CARE mit Leistung bis zu 150 Objekte pro Minute

Wir garantieren zuverlässige und exakte Füllergebnisse und sicheres Versiegeln von Tiegeln und kleinen Flaschen aus Glas und Kunststoff. Durch verschiedene Maschinen- und Anlagenkonzepte gehen wir individuell auf Ihre Bedürfnisse ein und bieten ein breites Leistungsspektrum an. So können wir beispielsweise Tiegel mit einem Durchmesser von 100 mm problemlos mit flüssigen, viskosen oder hochviskosen Produkten füllen

Highlights

- Schleudern während des Füllvorgangs

- Heißsiegeln von Aluminiumfolien

- Servogesteuertes Vor- und Nachschrauben mit links/rechts Verschraubung

COLOR CARE mit Leistung bis zu 240 Objekte pro Minute

Mascara, Lipgloss und Eyeliner bis zu 240 Objekte pro Minute

Mit maximaler Prozesssicherheit und exakter Steuerung übertreffen wir die Erwartungen unserer Kunden. Unsere ausgezeichnete Verschlusstechnik funktioniert auch bei instabilen und konischen Behältnissen. Die von groninger entwickelte, eigens gefertigte, verschleißfreie und äußerst kompakte Rotationskolbenpumpe sorgt für eine schnelle und besonders einfache manuelle Reinigung.

Highlights

- Heißfüllen von Lipgloss

- Verarbeiten von hochviskosen Produkten

- 100 % In-Prozess-Kontrolle (IPK)

Make-up bis zu 120 Objekte pro Minute

Hohe Flexibilität und volle Kontrolle - mit unseren Prozesslösungen werden wir all Ihren Anforderungen beim Abfüllen von Make-up Fläschchen gerecht. Aufgrund jahrelanger Erfahrung beim Handling von empfindlichen und hochwertigen Objekten garantieren unsere Konzepte Ihnen eine schonende Verarbeitung ohne Beschädigung und Verschmutzung, sowie gleichzeitig minimalsten Produktverlust und kürzeste Rüstzeiten.

Highlights

- Bis zu drei Verschlusskomponenten

- 100% In-Prozess-Gewichtskontrolle

- Markieren durch Laser

Nagellack bis zu 120 Objekte pro Minute

Hervorragende Maschinenkonzepte mit hoher Sicherheit und minimalem Produktverlust sind unser Anspruch bei der Verarbeitung von Flaschen mit Schraubpinseln. Von der kompakten Sternmaschine mit manueller Objektzuführung bis hin zur hochautomatisierten, mehrstellig getakteten Linearmaschine bietet unser Portfolio Lösungen für all Ihre Anforderungen im Bereich der Nagellack-Verarbeitung.

Highlights

- Bis zu drei Verschlusskomponenten

- Abfüllen von Glitterprodukten

- Geprüfte ATEX-Ausführung möglich

BODY & HAIR CARE mit Leistung bis zu 240 Objekte pro Minute

Flexibel und individuell abgestimmt auf Produkt und Objekt füllen wir flüssige Seife, Körper- und Haarpflegeprodukte ab. Die maximale Endprodukt-Qualität ist unser Ziel. Einfache und werkzeuglose Formatwechsel, redundante Füllsysteme sowie formatteillose Zuführungen sind nur ein kleiner Teil unserer Lösungen, um Ihnen die höchste Anlagenverfügbarkeit zu ermöglichen.

Highlights

- Sehr hohe Füllvolumina möglich (bis zu 1 Liter)

- Produktwechsel innerhalb von Minuten

- Füllen von zweiphasigen Produkten

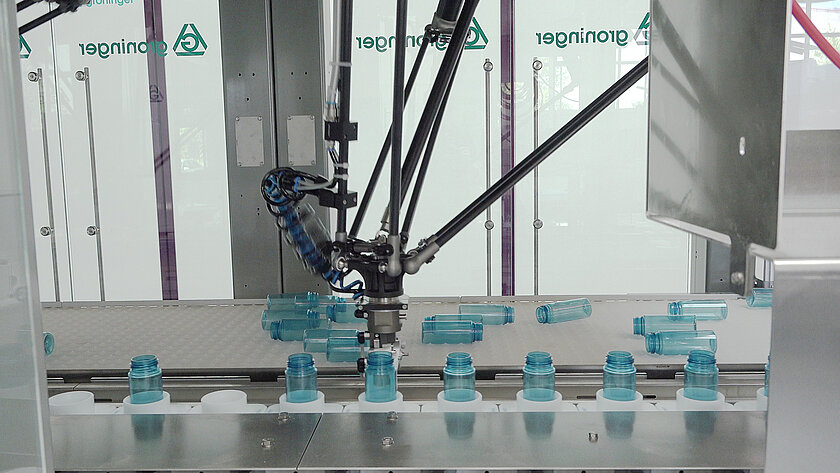

Roboter-Sortierung und -Zuführung

Mit unserem ganzheitlichen Beratungs-Know-how und unserer Erfahrung sind wir in der Lage, Sie zu allen Belangen rund um den Bereich der kosmetischen Abfüllung zu beraten und zu unterstützen. Zudem bieten wir Ihnen ein umfassendes Wissen im Bereich der Robotertechnik aufgrund einer Vielzahl umgesetzter Projekte. So bieten wir Ihnen die best möglichen Prozesse für Ihre Anforderungen.

Highlights

- Depalettieren von Trays von der Palette/von Paletten

- Verarbeiten von Trays und Kartons mit Gefache

- Sortieren von Objekten aus Schüttgut

- Universelle Lösung für Glas- und Kunststoffobjekte

- Handlingsroboter: Ausblasen über Kopf

- Positionieren von Flaschen und Montagetätigkeiten

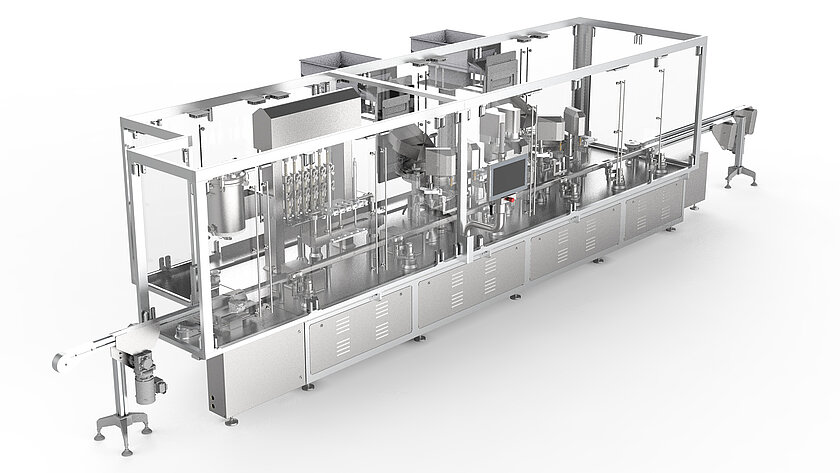

Unsere ausgewählte Komplettlösungen für die Kosmetik-Industrie

Mit unseren ausgewählte Komplettlösungen bieten wir Ihnen ein ganzheitliches Konzept für Abfüllanlagen in der kosmetischen Industrie. Der Clou: Sie bekommen durch eine Vielzahl an Wahlmöglichkeiten in Ausrüstung und Verwendung einen sehr großen Gestaltungsspielraum – so können Sie flexibel, schnell und zukunftsorientiert handeln. In diesen Anlagen steckt unser gesamtes Know-how.

Unsere Ready Engineered Philosophie ermöglicht kurze Lieferzeiten statt zeitraubender Planungs- und Konstruktionsphasen. Ready Engineered heißt für Sie von Beginn an Sicherheit. Sicherheit für Ihre Produktionsplanung und für die zu verarbeitenden Produkte – vom Duftwasser bis zum Haarpflegeprodukt, vom Nagellack bis zum Mascarastift.

Wir haben an alle Herausforderungen gedacht. Damit Sie schneller durchstarten können.