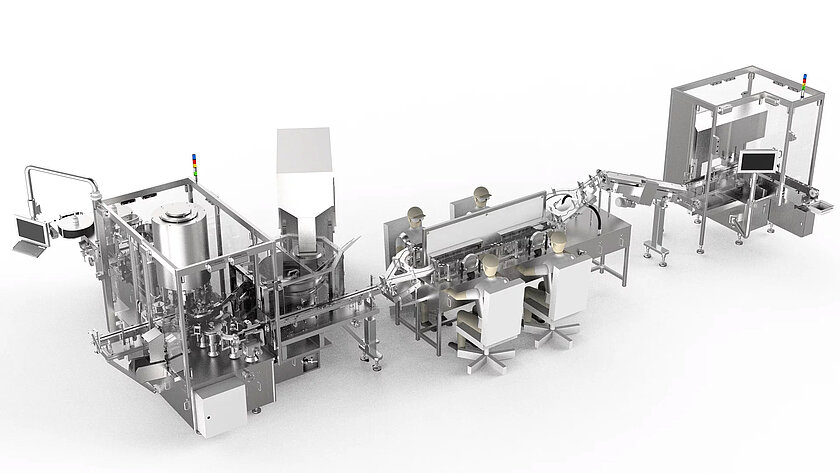

Nachverarbeitung - Etikettieren, Kolbenstangen-, Fingerflansch- und Safety Device-Montage

Bei der Nachverarbeitung ist eine schonende und qualitativ hochwertige Verarbeitung der Primärpackmittel von immenser Bedeutung. Daher können Nachverarbeitungsanlagen von groninger mit einem berührungslosen Transport für die Primärpackmittel ausgestattet werden.

Durch die modulare und kompakte Bauweise können die Anlagen flexibel an Ihre Anforderungen und Packmittel angepasst, sowie Standardanlagen können einfach mit zusätzlichen Prozessmodulen erweitert werden.

Prozessschritte der Nachverarbeitung

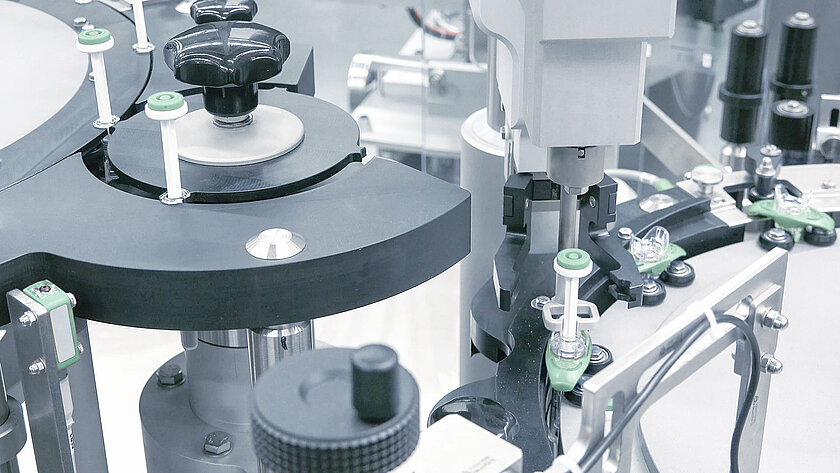

Kolbenstangenmontage

Beim Prozess der Kolbenstangenmontage ist es entscheidend, dass die Integrität des pharmazeutischen Packmittels und des Kolbenstopfens gewährleistet wird. groninger hat für den Prozess der Kolbenstangenmontage ein patentiertes System am Markt, welches ausschließt, dass bei der Montage der Kolbenstange der Kolbenstopfen in der Spritze weder axial verschoben noch in Rotation versetzt wird. Alle hierfür benötigten Parameter sind einstellbar und können im Rezeptmanagement gespeichert werden. Dadurch bietet groninger eine sichere und zuverlässige Lösung für Ihren Montageprozess.

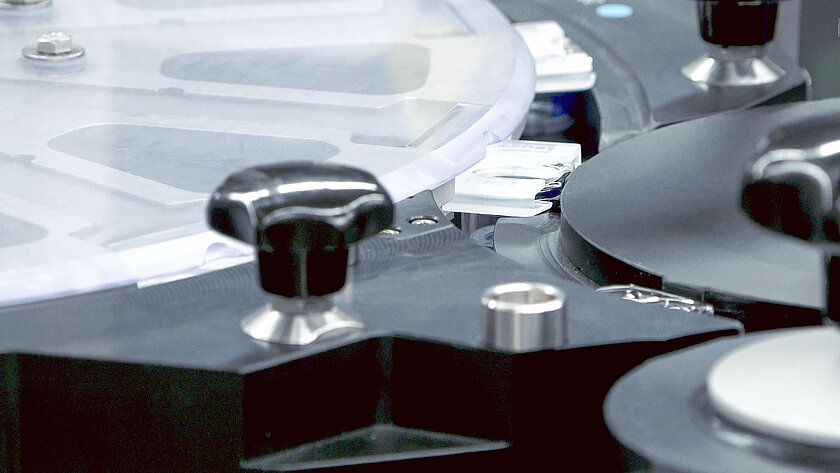

Etikettieren

Etiketten sind ein wichtiger Träger von Informationen und haben daher eine sehr große Bedeutung für die pharmazeutischen Produkte. Deshalb ist es umso wichtiger, dass das Etikett mit den richtigen Daten bedruckt und am vorgesehenen Platz aufgebracht wurde. groninger garantiert eine höchst präzise und schonende Etikettierung von unterschiedlichen pharmazeutischen Primärpackmittel. Etiketten, die als fehlerhaft detektiert wurden, werden nicht auf das Packmittel aufgebracht. Alle Primärpackmittel werden mit einem fehlerfreien Etikett versehen und etikettiert.

Backstopmontage / Fingerflanschmontage

Der Backstop hat die Aufgabe zu verhindern, dass der Kolbenstopfen aus dem Spritzenzylinder unbeabsichtigt herausgezogen wird. Neben dieser Bremsfunktion, sichert der Backstop die Kolbenstange gegen ein Verdrehen, damit die Kolbenstange bei der Applizierung nicht ungewollt herausgedreht werden kann. Zusätzlich kann mit Hilfe des Backstops eine verbesserte Fingerauflage geschaffen werden. Mit den groninger Montageanlagen werden die Backstops vollumfänglich und schonend auf den Flansch der Spritze montiert, um die Grundfunktionen des Backstops zu gewährleisten und keine Beschädigungen an den Glas- oder Kunststoffspritzen zu verursachen.

Safety Device-Montage

Auf der ganzen Welt werden jährlich Milliarden von Injektionen verabreicht. Leider kommt es bei dieser großen Anzahl an Injektionen zu zahlreichen Nadelstichverletzungen, die ansteckende Krankheiten nach sich ziehen können. Deshalb ist es umso wichtiger vorfüllbare Spritzen mit Sicherheitskomponenten bzw. Safety Devices zu montieren. Von halbautomatischen Lab-Equipment bis hin zu High-Speed Montageanlagen für Safety Devices hat groninger alles in seinem Nachverarbeitungsportfolio.

Nachverarbeitungsanlagen für vorgefüllte Spritzen, Vials und Karpulen

Nachverarbeitungslinie bis zu 70 Objekte pro Minute

- 3 in 1 Verarbeitung aller gängigen Spritzen, Vials und Karpulen

- Modulare Erweiterung von Backstop-, Fingerflansch- und Safety Device-Montage

- Patentierte elektromotorische Kolbenstangenmontage

- Integrierte Schlechtetikettenentnahme ohne Objektverlust

- Diverse Prüfsysteme Sensorik / Bildverarbeitungssysteme

- Integration aller gängigen Druckersysteme

- Handlings Systeme für das Zuführen, Magazinieren und Puffern

Nachverarbeitungslinie bis zu 300 Objekte pro Minute

- 3 in 1 Verarbeitung aller gängigen Spritzen, Vials und Karpulen

- Modulare Erweiterung von Backstop-, Fingerflansch- und Safety Device-Montage

- Patentierte elektromotorische Kolbenstangenmontage

- Integrierte Schlechtetikettenentnahme ohne Objektverlust

- Diverse Prüfsysteme Sensorik / Bildverarbeitungssysteme

- Integration aller gängigen Druckersysteme

- Automatische Spliceeinheit bei voller Leistung

- Handlings Systeme für das Zuführen, Magazinieren und Puffern

Nachverarbeitungslinie bis zu 600 Objekte pro Minute

- 3 in 1 Verarbeitung aller gängigen Spritzen, Vials und Karpulen

- Modulare Erweiterung von Backstop-, Fingerflansch- und Safety Device-Montage

- Patentierte elektromotorische Kolbenstangenmontage

- Integrierte Schlechtetikettenentnahme ohne Objektverlust

- Diverse Prüfsysteme Sensorik / Bildverarbeitungssysteme

- Integration aller gängigen Druckersysteme

- Automatische Spliceeinheit bei voller Leistung

- Handlings Systeme für das Zuführen, Magazinieren und Puffern