Waschen und Montieren von Primärpackmitteln für die pharmazeutische Industrie

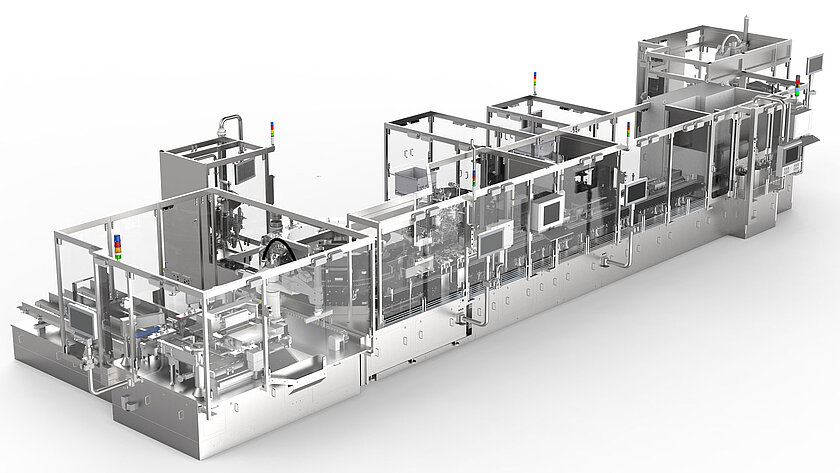

Mit unseren Anlagen zum Waschen und Montieren, decken wir einen großen Teil jener Prozessschritte ab, die zur Herstellung von vorsterilisierten Packmittel notwendig sind.

Sei es das Waschen und Depyrogenisieren der Primärverpackungen, die Anwendung verschiedener Silikonisierungsmöglichkeiten oder die Montage von Verschlusssystemen und Bördelkappen, groninger bietet immer die passende Anlagenlösung.

Prozessschritte bei der Herstellung von RTU Packmitteln

Bei der Herstellung von ready-to-use Spritzen, Vials oder Karpulen fallen unterschiedliche Prozessschritte an – vom Zuführen der Container über Waschen und Silikonisieren bis hin zum Magazinieren in Nest und Tub.

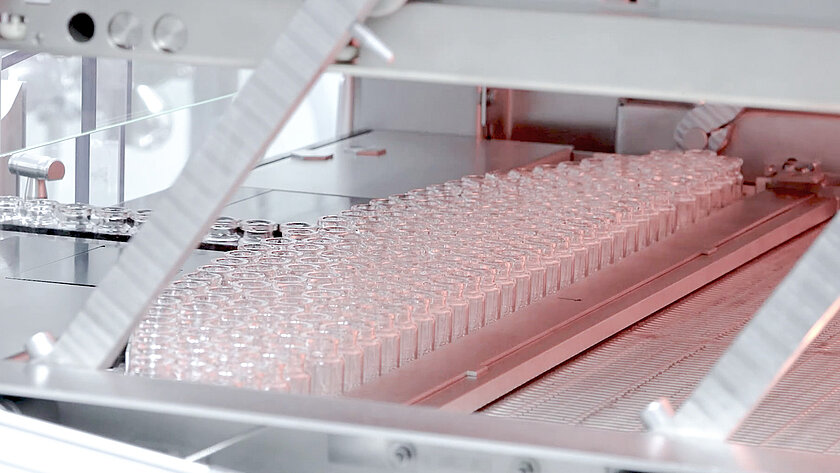

Zuführung der Glascontainer

Wenn die vorfüllbaren Glascontainer den Anlagen zugeführt werden, sind sie in der Regel in Trays verpackt – die genaue Verpackung variiert aber je nach Primärverpackung und benötigt jeweils ein passendes System für Zuführung bzw. Handling.

Mit unseren Anlagen sind Sie da gut versorgt: groninger hat mehrere etablierte Lösungen im Portfolio, von einem Detray-Modul über ein Depalletier-Modul bis hin zu hochmodernen Roboterapplikationen.

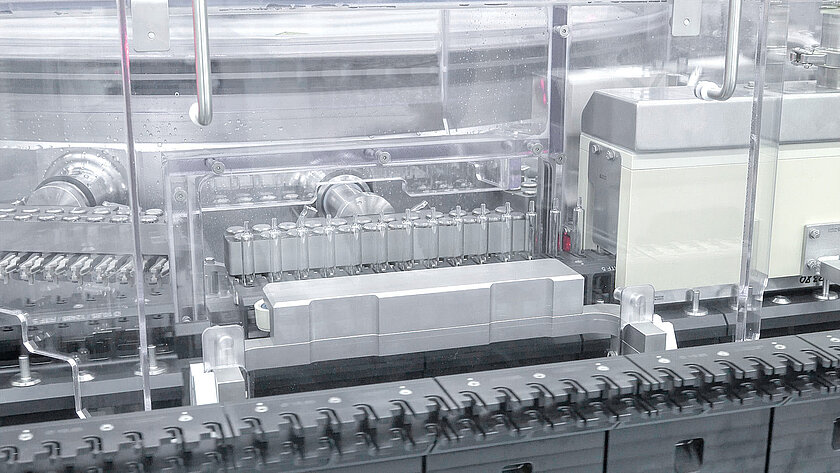

Waschen

In einem Waschmodul werden die Glascontainer gereinigt und getrocknet. In unseren Anlagen haben wir dabei den Medienverbrauch auf ein Minimum reduziert und erreichen dennoch ein hervorragendes Waschergebnis bis zu einer 3-log reduzierten Reinigung.

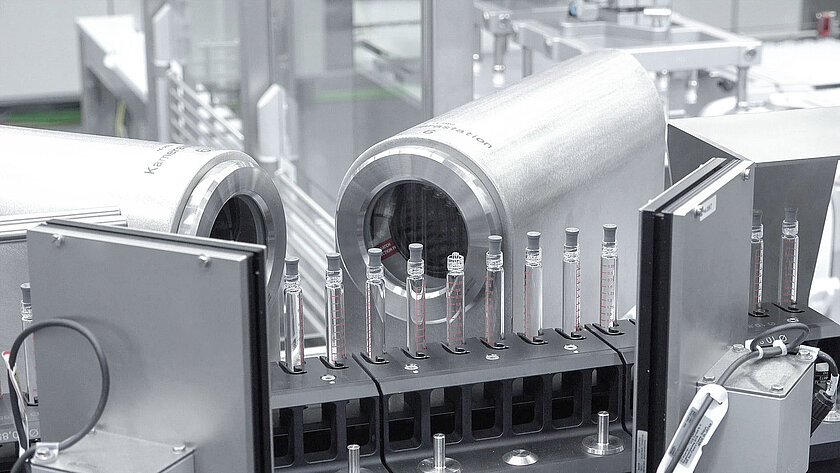

Sterilisieren / Depyrogenisieren

Der von groninger entwickelte Sterilisierungsprozess legt großen Wert auf einen schonenden Verarbeitungsprozess, auf leichte Zugänglichkeit aller Bestandteile für die problemlose Wartung und zugleich auf höchste Qualität und Prozesssicherheit.

Die schonende Sterilisierung wird in unserem neuartigen Steriltunnel bereits über eine sanfte Erwärmung im Einlaufbereich erreicht. Die Qualität wird außerdem durch den Einsatz von High-End-Sterilfiltern im Sterilisierbereich sichergestellt.

Ein großer Vorzug dieser Vorgehensweise ist die geringe Temperaturdifferenz am Objekt – diese zeichnet diesen Prozess aus, zudem wird ein Overkill im Sterilprozess vermieden.

Durch den modularen Aufbau des Prozesses lassen sich leicht Anpassungen vornehmen. Zugleich wurde sowohl auf Lösungen verzichtet, bei denen am Auslauf zum Sterilbereich kein „Ring of Concern“ vorhanden ist, als auch auf kritische aufblasbare Dichtungen.

Silikonisieren

Vor dem Hintergrund steigender Qualitätsanforderungen sowie der Zunahme biotechnologisch erzeugter, proteinbasierter Arzneimittel ist eine gleichmäßige Beschichtung von den Oberflächen der Glascontainer mit reduzierten Silikonölmengen notwendig.

In unseren Anlagen ist es uns gelungen, die Einsprühmengen an Silikonöl zu minimieren, ohne dass dies die Gleitkräfte beeinflusst.

Prüfen

Kontrolle leicht gemacht: Alle Systeme bzw. Prozessschritte können mit verschiedenen Prüfsystemen ausgestattet werden. Sensoren, hochmoderne Kamerasysteme und komplexe Röntgensysteme lassen sich in den Ablauf integrieren.

Mit diesen Systemen lassen sich geometrische Parameter prüfen und Glasbehälter auf kosmetische Mängel inspizieren. So stellt groninger beispielsweise ein Kamerasystem bereit, das die Fingerauflage einer Spritze auf Glasabplatzungen und die korrekte Kontur überprüft.

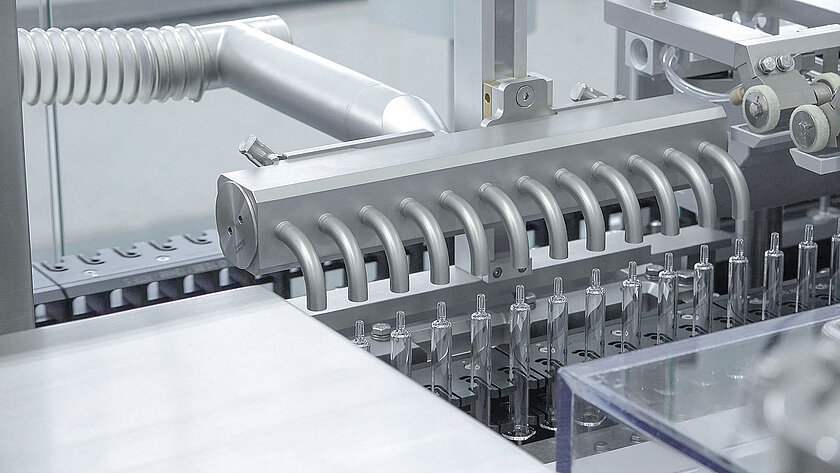

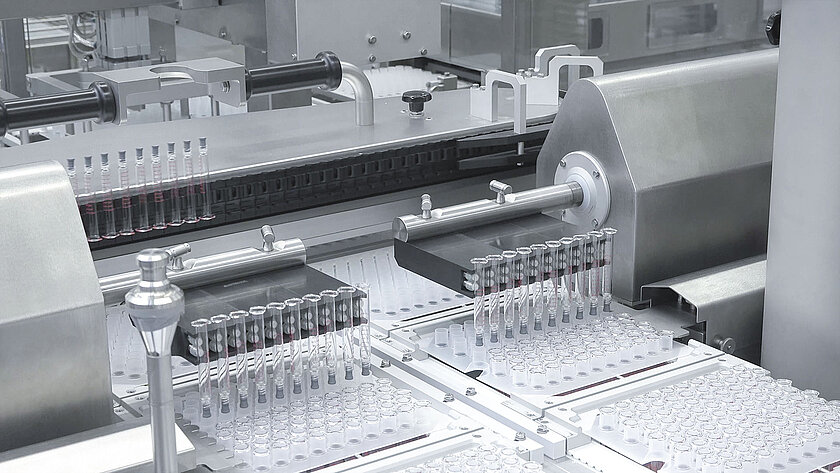

Montieren

Einer der wichtigsten Prozessschritte dieser Linien ist das Montieren von verschiedenen Verschlüssen, Nadelschutzelementen und Kappen.

Die Verschlüsse haben unterschiedliche Eigenschaften und Aufgaben. Bei Spritzen muss die Kanüle bis zur Injektion vor Beschädigung geschützt und steril gehalten werden. Des Weiteren gibt es Verschlüsse, die mit einem Nadelschutzmechanismus ausgestattet sind, der einerseits vor Verletzungen schützen sowie andererseits eine versehentliche Wiederverwendung verhindern soll.

In der Anlage werden all diese Komponenten über ein eigens entwickeltes Bevorratungs- und Zuführsystem zu den jeweiligen Montagestationen transportiert und dort auf den Glascontainer montiert. Eine präzise Assemblierung der Verschlüsse ist dabei von immenser Wichtigkeit.

Alle Montageprozesse werden im Nachgang von unterschiedlichsten Inspektionssystemen überprüft.

Magazinieren

Die verarbeiteten und fertig verschlossenen Glasbehälter können anschließend in verschiedenste pharmazeutische Endverpackungen eingesetzt werden.

Eine schonende Umsetzung ist dabei von großer Bedeutung, auch hier dürfen sich die Glasbehälter über den kompletten Prozess nicht berühren. Ein Inspektionssystem kann abschließend überprüfen, dass die Endverpackungen vollständig bestückt wurden.

Exzellente Anlagenkonzepte zum Waschen und Montieren von pharmazeutischen RTU Primärpackmitteln

Unabhänging davon welche pharmazeutischen Primärpackmittel Sie für Ihr Portfolio herstellen möchten, wir können Ihnen ein passendes Verarbeitungs- und Anlagenkonzept für das Waschen, Silikonisieren und Montieren von ready-to-use Packmittel liefern. Auch innerhalb der Verarbeitung von einem pharmazeutischen Packmittel kann groninger auf Ihre individuellen Anforderungen eingehen. Als Beispiel kann hier das Montagemodul genannt werden, das in der Lage ist, Nadel- oder Luerlockspritzen mit verschiedensten Verschlusskomponenten zu assemblieren. Mit Hilfe einer sehr geringen Anzahl an Formatteilen kann das Montagemodul für die gewünschten Verschlusssysteme bzw. Verschlusskomponenten eingerichtet werden. Durch die langjährige Erfahrung bei der Verarbeitung von pharmazeutischen Primärpackmittel und das Verständnis über die Packmittel und ihren zugehörigen Komponenten ist groninger in der Lage Ihnen ein Höchstmaß an Präzision bei der Montage und Flexibilität innerhalb des Anlagenkonzepts zu bieten.

Technische Features und Highlights der Herstelllinien für RTU Spritzen, Vials und Karpulen

- Waschen: Zum Waschen der Glasbehälter wird WFI (Water For Injection) eingesetzt. Mit über Jahrzehnte gesammeltem Know-how über das Waschen von Glascontainern sorgt groninger dafür, dass auch die höchsten Anforderungen in der Pharmaindustrie erfüllt werden.

- Silikonisieren: Um auf den gewünschten Oberflächen der Glasbehälter eine homogene Silikonschicht zu erzeugen, nutzt groninger seine langjährige Entwicklungserfahrung im Bereich der Silikonisierung. Bei der Herstellung steriler Spritzen und Karpulen werden hierbei patentierte Silikonisierungstechniken eingesetzt.

- Schonende Verarbeitung: Um Glasbruch (und daraus resultierende Partikel und Kontaminierungen) zu vermeiden, werden die Glasbehälter kontaktlos verarbeitet und transportiert. Dabei wird insbesondere darauf geachtet, dass sich die Glasbehälter über die kompletten Anlagen nicht berühren können.

- Laminar Flow-Freundlichkeit: Die verschiedenen Anlagenkonzepte bzw. Maschinenmodule sind so konstruiert, dass es über den Glasbehältern keine Bewegungen gibt. Dies verhindert das mögliche Verwirbeln von eventuell erzeugten Partikeln und stellt sicher, dass die Glasbehälter immer unter First Air stehen.

- Flexibilität: Unsere Anlagen bieten Ihnen das maximum an Flexibilität zu Verarbeitung verschiedenster Objekte und Objektgrößen

- Höchste Prozesssicherheit: Unsere Anlagen zum Waschen und Montieren von RTU Spritzen, Vials und Karpulen bieten höchste Prozesssicherheit durch verschiedenste Kamera- und Inspektionsmöglichkeiten