Aseptische Verarbeitung von RTU Spritzen, Vials und Karpulen im Nest

Der Einsatz von ready-to-use Packmitteln (RTU) in der pharmazeutischen Industrie steigt seit vielen Jahren stetig an. Dafür gibt es mehrere Gründe: zunehmend kleiner werdende Batch-Größen, gestiegene Anforderungen an die Flexibilität in der Herstellung und und vor allem sinkende Preise für RTU Packmittel und damit Kostenvorteile für Ihre Investitionen.

groninger Anlagen verarbeiten vorsterilisierte Spritzen, Vials und Karpulen. Ein Formatwechsel ist werkzeuglos möglich und daher mit minimalem Rüstaufwand verbunden. Das verkürzt die Stillstandszeit und ermöglicht ein Höchstmaß an Flexibilität in der aseptischen Abfüllung.

Die vorsterilisierten RTU Packmittel werden einfach- oder doppelverpackt in den Reinraum an die Linie gebracht und dort über einen halb- oder vollautomatisierten Prozess ausgepackt. Für den Transfer der Packmittel in den aseptischen Bereicht gibt es zwei grundlegende Methoden, zum einen die Außendekontamination mithilfe von E-Beam, mittels H2O2 oder zum anderen der No-Touch-Transfer (NTT). In den vergangenen Jahren hat zudem der No-Touch-Transfer zunehmend an Bedeutung gewonnen und findet Einsatz bei Small-Batch- bis hin zu High-Speed-Anwendungen.

Prozessschritte zum Verarbeiten von Spritzen, Vials und Karpulen im Nest

Einlauf

Außendekontamination, Bestrahlung oder berührungsloser aseptischer No-Touch-Transfer (NTT)

Der Transfer von Packmitteln in den aseptischen Bereich ist ein entscheidender Prozessschritt in der pharmazeutischen Industrie. Vor allem bei kleinen und mittleren Produktionsmengen stellt der sogenannte No-Touch-Transfer eine Möglichkeit des aseptischen Transfers dar, die neben der Außendekontamination mittel E-Beam oder H2O2 an Bedeutung gewinnt.

Als Marktführer im Bereich der Verarbeitung von RTU Packmitteln war groninger einer der ersten pharmazeutischen Maschinenbauer, dessen Anlagen in Kombination mit einem E-Beam oder der No-Touch-Transfer-Technologie in Betrieb genommen und von den regulatorischen Behörden zur GMP-Produktion freigegeben wurden.

Im Bereich des berührungslosen aseptischen Transfers unterscheidet man zwischen verschiedenen Ausbaustufen:

No-Touch-Transfer basic

Beim NTT basic wird das RTU Packmittel in zwei Beuteln verpackt an die Linie angeliefert. Der äußere Beutel wird manuell unter einer laminaren Luftströmung der Klasse A aufgeschnitten und mit das Tub anschließend im Innenbeutel in die Zone der Klasse B übergeschoben. Dort wird der Beutel automatisch geklemmt, geschnitten und das Tub halbautomatisch in den Bereich der aseptischen Abfüllung (Reinraumklasse A/ISO 5) transferiert.

No-Touch-Transfer advanced

Auch für den vollautomatisierten NTT wird das RTU Packmittel in zwei Beuteln verpackt angeliefert. Der äußere Beutel wird an der Linie manuell oder automatisch geklemmt, aufgeschnitten und das RTU Packmittel im Innenbeutel in die Klasse B hinübergeschoben. Im Anschluss daran erfolgt ein vollautomatisiertes Beutelstrecken gefolgt von einem vollautomatisierten Klemmen und Aufschneiden. Danach wird das Tub in den aseptischen Kernbereich (Reinraumklasse A/ISO 5) weiter transportiert.

H2O2

Für die Dekontamination mit H2O2 wird ein nur einfach verpackter Beutel manuell unter laminarer Klasse-A-Luft aufgeschnitten und in die Dekontaminationskammer transferiert. Mittels H2O2 erfolgt dann eine 6-log-Außendekontamination des RTU Tubs und ein manueller oder automatischer Übergang in die Klasse A.

E-Beam

Für die E-Beam-Außendekontamination werden einfach verpackte RTU Packmittel ausgepackt und mit bis zu sieben Packeinheiten pro Minute in eine E-Beam-Kammer eingeführt. Diese ermöglicht einen sicheren Prozess mit einer 6-log-Rate – so können die Packmittel steril eingebracht werden.

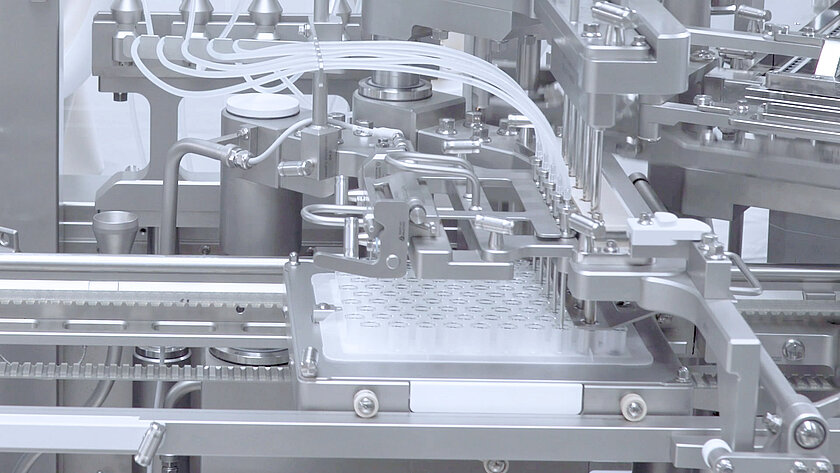

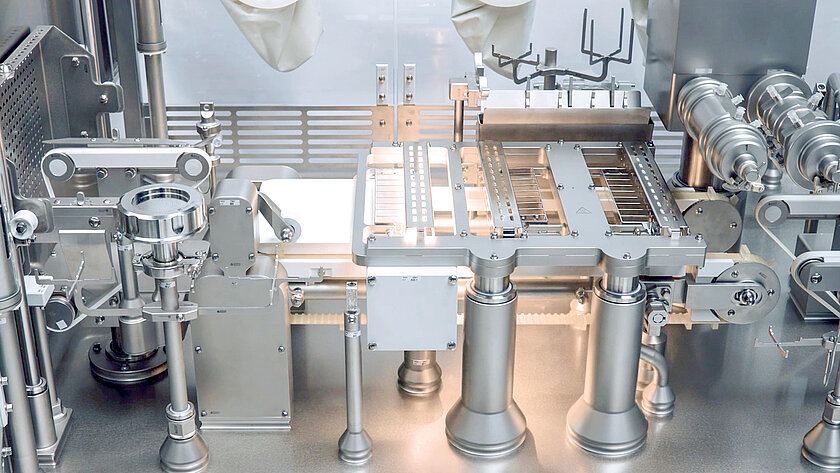

Öffnen

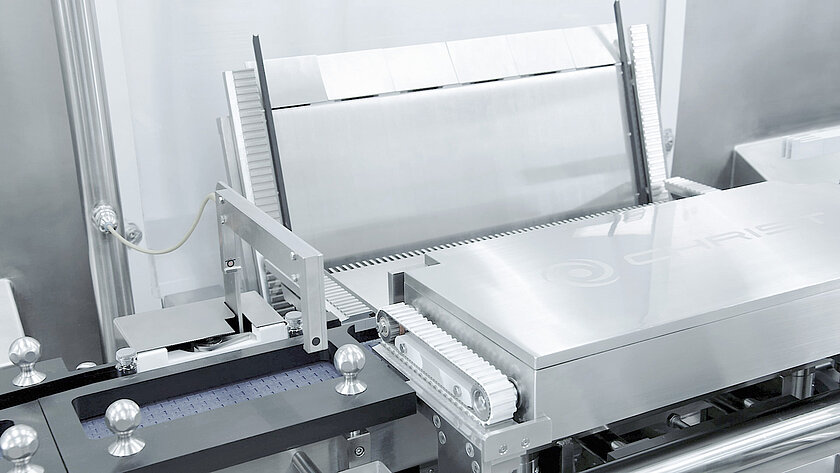

Öffnen von Tubs ohne Kontaminationsrisiko

Für das Öffnen von Tubs nutzt groninger die patentierten Abziehrollen. In dem Prozess werden zunächst die Klebestellen der Packmittelabdeckung erhitzt, um die Klebeverbindung zu lösen – so wird auch die Partikelgenerierung beim Abziehen des Liners minimiert. Dabei ziehen Vakuumroller mit einheitlicher Geschwindigkeit extrem prozesssicher und reproduzierbar Lid und Liner zugleich ab.

Dieser Prozess garantiert auch einen idealen First-Air Kontakt, d.h. oberhalb der geöffneten Packmittel finden keinerlei Bewegungen statt, dadurch wird verhindert, dass das Primärpackmittel mit Partikeln kontaminiert wird.

Unabhängig von der Ausbringleistung der Maschine ermöglicht diese Technologie einen kontinuierlichen und von der tatsächlichen Batch-Größe unabhängigen Verarbeitungsprozess.

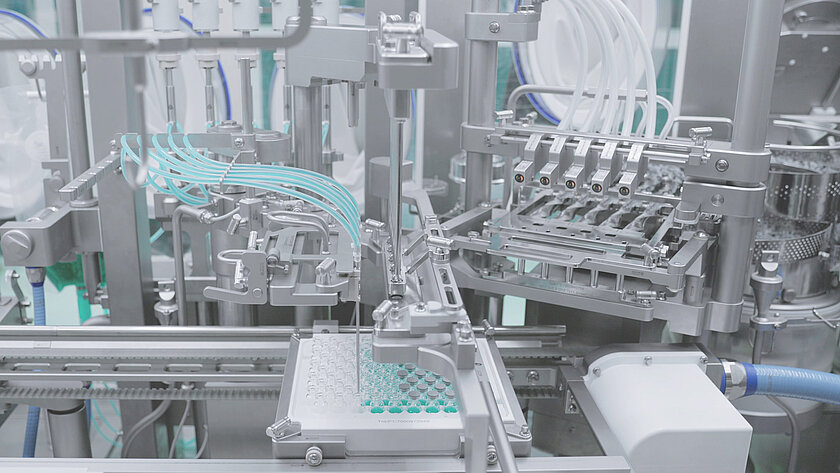

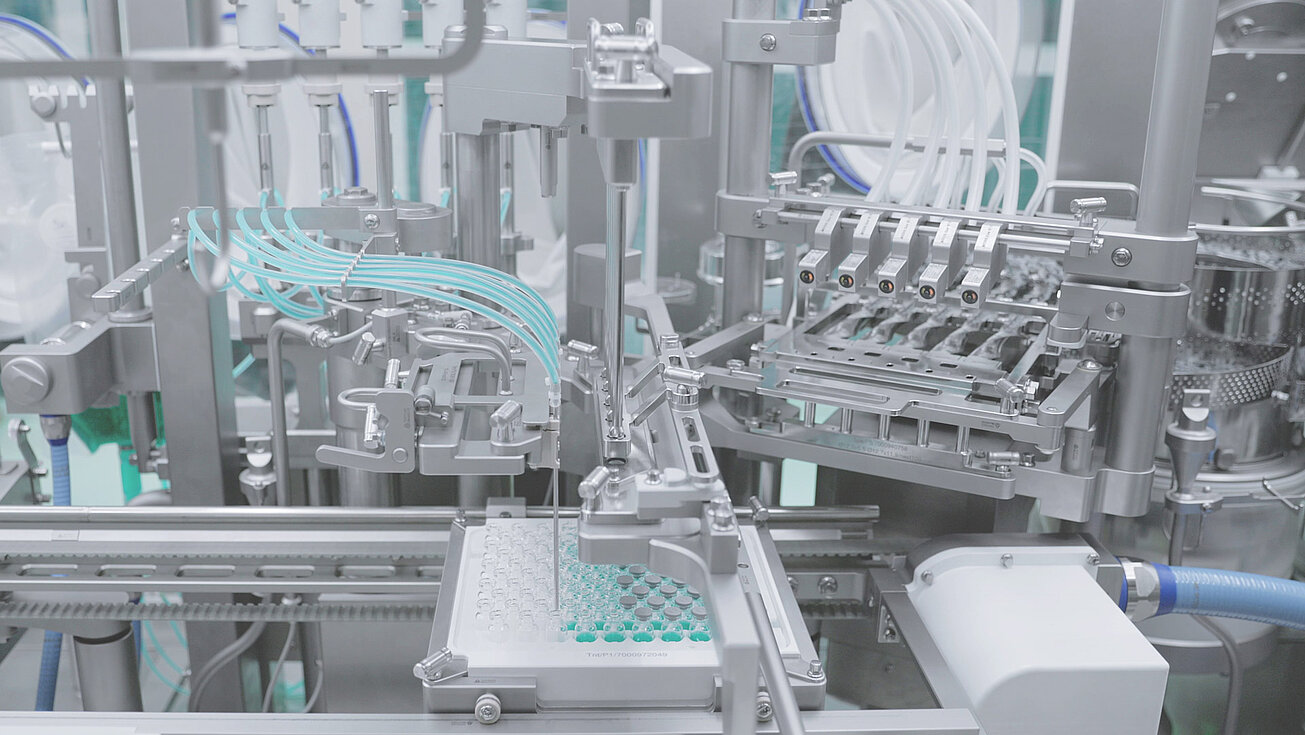

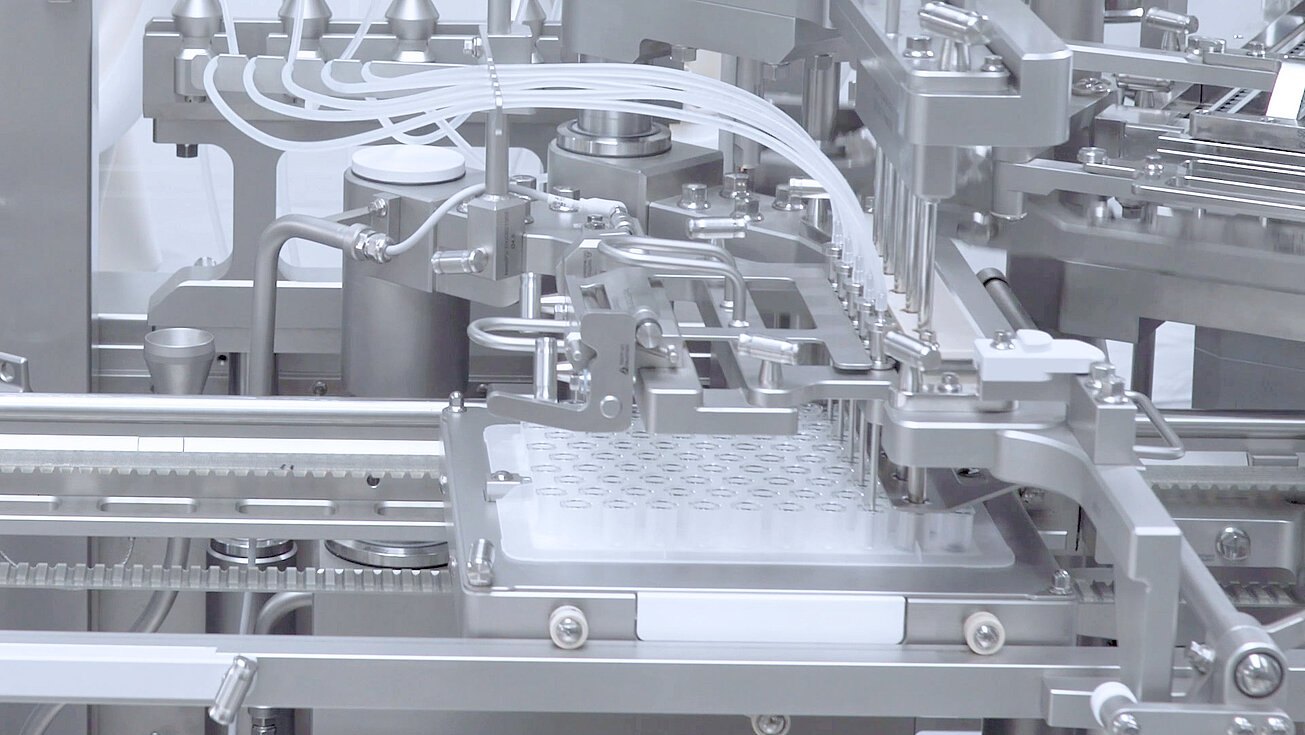

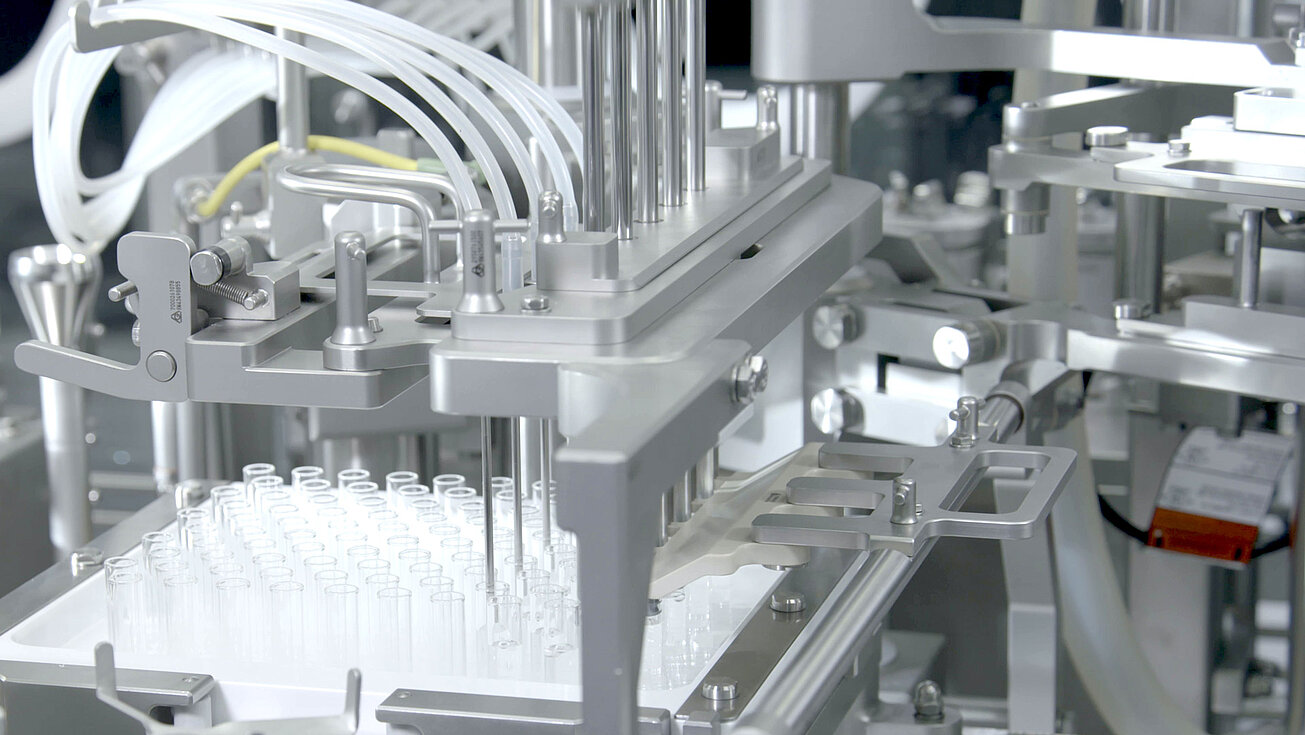

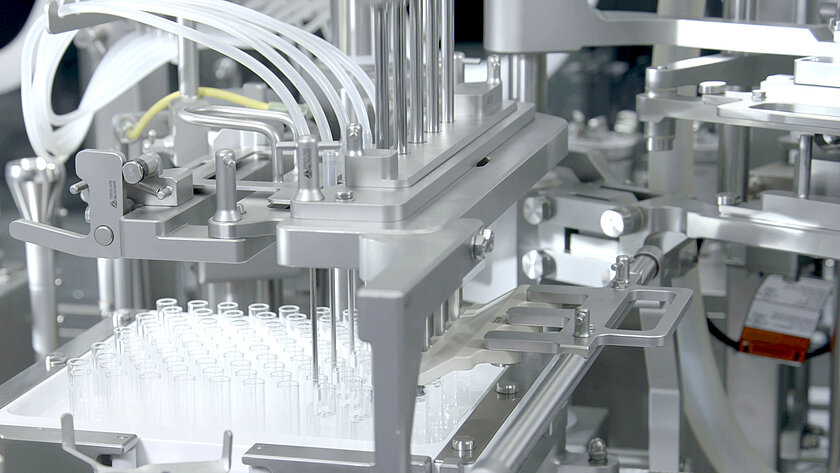

Füllen & Verschließen

Füllen und Verschließen von genesteten RTU Objekten

Für die Befüllung von Objekten gibt es zwei grundlegende technologische Ansätze: Man unterscheidet Anlagen mit einer statistischen In-Prozess-Kontrolle (IPK) und Anlagen mit einer 100% In-Prozess-Kontrolle (IPK). Der entscheidende Unterschied zwischen den beiden Methoden ist, ob und zu welchem Zeitpunkt die Objekte aus dem Tub bzw. Nest ausgehoben und gewogen werden.

Andere Teilprozesse wie das Füllen oder Stopfensetzen mit Vakuum, das Begasen bei Sauerstoffempfindlichen Produkten sowie die Verwendung von verschiedenen Füllsystemen (z.B. wie Rotationskolbenpumpen, Peristaltikpumpen oder Zeit-Druck-Füllsysteme), können bei beiden Anlagenarten umgesetzt werden.

Anlagen mit statistischer In-Prozess-Kontrolle (IPK)

In Anlagen mit statistischer In-Prozess-Kontrolle (IPK) kann das Primärpackmittel während des Füll- und Verschließvorgangs im Nest verbleiben. Die Anzahl der Wiegevorgänge kann über die Benutzerschnittstelle eingestellt werden - dafür werden die Objekte mit Roboterarmen ausgehoben und vor beziehungsweise nach dem Füllvorgang gewogen.

Spritzen und Karpulen verbleiben bei diesen Anlagen nach dem Verschließen im Nest und können nach dem Ausschleusen aus dem aseptischen Bereich inspiziert werden.

Bei Vials unterscheidet sich der Vorgang unter Umständen: Wenn sie mit integrierten Stopfenkappen verschlossen werden, ist der Ablauf zwar ähnlich wie bei Spritzen und Karpulen. Wenn sie allerdings in traditioneller Weise mit Stopfen und Alukappen verschlossen werden sollen, werden die Vials durch einen Roboterarm aus den Nestern gehoben und vereinzelt der Bördelmaschine zugeführt.

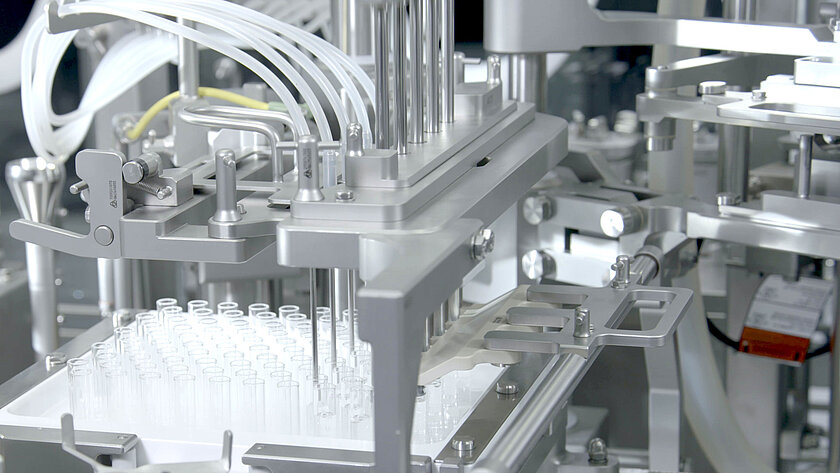

Anlagen mit 100% In-Prozess-Kontrolle (IPK)

Anlagen mit 100% In-Prozess-Kontrolle (IPK) zeichnen sich dadurch aus, dass alle zu befüllenden Objekte (Spritzen, Vials oder Karpulen) vereinzelt in ein Transportsystem gebracht werden, nachdem Lid und Liner vom Nest entfernt wurden.

Da die Vereinzelung mit einem Roboterarm geschieht, hat das nur minimalsten Einfluss auf die laminare Umströmung der Objekte. Vereinzelt können sie zudem auch jedes für sich gewogen werden. So ist es bei diesen Anlagen möglich, den Füllbereich noch genauer zu definieren, da eine direkte Anpassung ebenso möglich ist wie das Nachdosieren oder das Nachsetzen von fehlenden Stopfen.

Durch den von groninger etablierten Smartfill-Prozess wird zudem bei diesen Anlagen der Produktverlust beim An- beziehungsweise Leerfahren minimiert.

Gefriertrocknung

Integration von Prozessen zur Gefriertrocknung

Die Gefriertrocknung wird seit Jahren erfolgreich angewendet, um die Lebensdauer von Medikamenten zu erhöhen. Für diesen Prozessschritt gibt es von unterschiedlichen Anbietern geeignete und bewährte Technologien, die sich in Abfüllanlagen von groninger integrieren lassen.

Von manueller GT-Beladung bis hin zu automatisierten Anlagen mit bis zu 600 Objekten pro Minute: Wir haben bereits mit nahezu allen Systemen weltweit Erfahrungen sammeln können. Dadurch können wir die Linienintegration von Gefriertrocknern und Beladesystemen problemlos auch nach Ihren spezifischen Anforderungen umsetzen. Sie wählen die beste Technologie aus, wir integrieren sie in unser Linienkonzept.

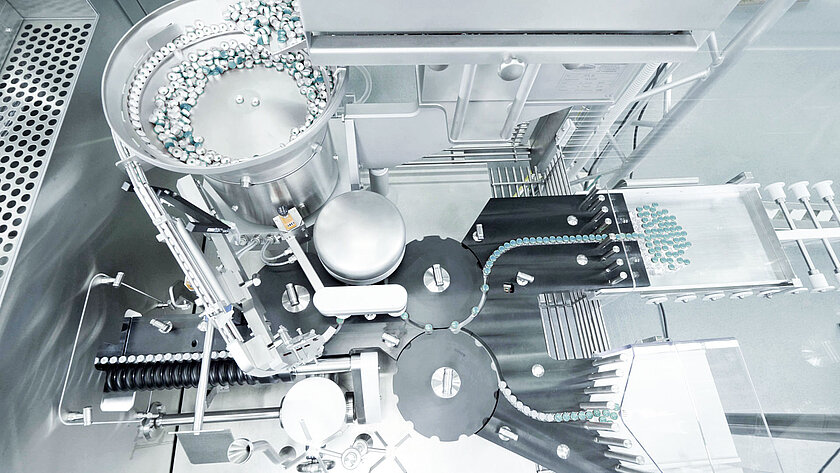

Bördeln

Das Verbördeln steht am Ende jeder Vialverarbeitung mit klassischen Aluminium Kappen. groninger setzt dabei auf das patentierte und bewährte Einscheibenbördelprinzip. Alle Vials werden über eine einzige, einstellbare Bördelscheibe verschlossen. Bei entsprechender Einstellung, können die Objekte in verschiedenen Leistungsklassen von 10 bis 600 Objekten pro Minute äußerst prozesssicher verschlossen werden.

Die Vorteile im Vergleich zu Lösungen mit mehreren Bördelscheiben ist dabei klar:

- Die Anlage lässt sich deutlich schneller umrüsten,

- das Prozessrisiko sinkt und

- Fehler im Prozess lassen sich ohne Zeitverzögerung erkennen und abstellen.

Außenreinigung

Außenreinigung gefüllter Produkte

Bei der Verarbeitung von toxischen Produkten rückt neben dem Produktschutz auch der Bedienerschutz deutlich in den Vordergrund. Für diese Produkte steigen deshalb die Anforderungen an die Außenreinigung der gefüllten Vials.

Ob in flüssiger Form oder als Pulver nach einem Gefriertrocknungsprozess - toxische Bestandteile treten bei personalisierten Medikamenten nicht selten auf. groninger hat einen Fokus seiner Arbeit auf deren Verarbeitung gelegt und bietet ein umfangreiches Portfolio von Lösungen an, die die Außenreinigung sicherstellen.

Nachverarbeitung

Wenn die Primärpackmittel pharmazeutisch verschlossen wurden, beginnt die Nachverarbeitung der Packmittel. Diese Prozessschritte können in der Regel außerhalb von traditionellen Reinräumen durchgeführt werden.

Zu den möglichen Arbeitsschritten in dieser Phase gehören:

- Inspektion der Primärpackmittel,

- Etikettieren,

- Einbau eines Fingerflansches oder eines Safety Devices und/oder

- das Eindrehen der Kolbenstangen.

Erst im Anschluss an diese Arbeitsschritte folgt das Verpacken in die finale Endverpackung.

groninger zielt hier immer auf eine ganzheitliche Lösung ab, wir bringen deshalb nicht nur eigene Expertise in Sachen Montage und Etikettieren mit, sondern kooperieren sehr eng mit namhaften Anlagenbauern im Bereich der Inspektion und Endverpackung.

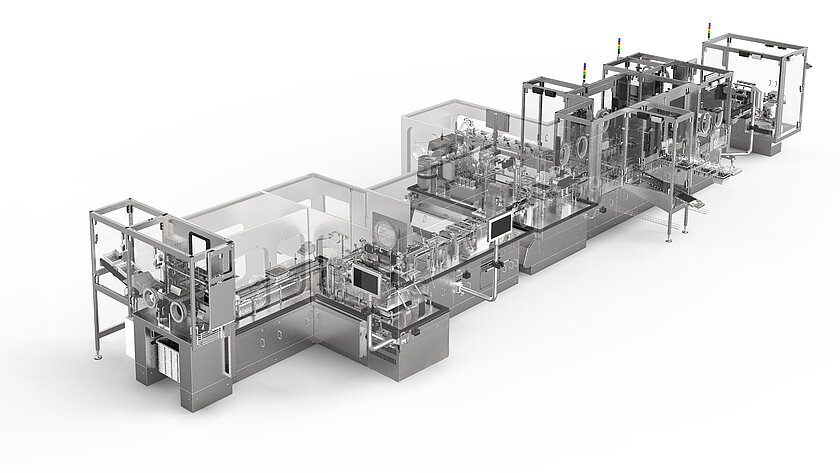

Herausragende Linienkonzepte zur Verarbeitung von RTU Spritzen, Vials und Karpulen im Nest

Führend in der Nestverarbeitung perfektionieren wir die effiziente Verarbeitung vorsterilisierter Objekte im Nest. Unsere technologischen Lösungen verhindern jegliche mikrobiologische Verunreinigung. Hohe Flexibilität, kurze Umrüstzeiten und exzellente Verarbeitungsqualität runden unsere Performance ab. Innovativ, erstklassig und absolut sicher: Technologie von groninger – für Pharmazeuten weltweit.

„Stand-Alone Anlage“ mit Leistung bis zu 80 Objekte pro Minute

- 3 in 1 Verarbeitung aller gängigen ready-to-use Spritzen, Vials und Karpulen in einer Tub/Nest-Konfiguration

-

Alle gängigen Füllsysteme möglich

-

Bewegbare Anlage

-

Standard Begasungs- und Vakuumfunktionen

-

Ausführung für oRABS-Systeme

Abfülllinie mit Leistung von 80 – 200 Objekte pro Minute

- 3 in 1 Verarbeitung aller gängigen ready-to-use Spritzen, Vials und Karpulen in einer Tub/Nest-Konfiguration

-

Alle gängigen Füllsysteme möglich

-

Standard Begasungs- und Vakuumfunktionen

-

Smartfill für minimalen Produktverlust

-

Manuelles bis vollautomatisches Handling aller Prozesse

-

Automatische In-Prozess-Kontrolle (IPK)

-

Ausführung für Isolatoren, offene und geschlossene RABS-Systeme

Abfülllinie mit Leistung von 200 – 400 Objekte pro Minute

- 3 in 1 Verarbeitung aller gängigen ready-to-use Spritzen, Vials und Karpulen in einer Tub/Nest-Konfiguration

-

Alle gängigen Füllsysteme möglich

-

Standard Begasungs- und Vakuumfunktionen

-

Smartfill für minimalen Produktverlust

-

Manuelles bis vollautomatisches Handling aller Prozesse

-

Automatische In-Prozess-Kontrolle (IPK)

-

Optional: Linienkonfiguration mit 100% In-Prozess-Kontrolle (IPK)

-

Ausführung für Isolatoren, offene und geschlossene RABS-Systeme

Abfülllinie mit Leistung von 400 – 1.000 Objekte pro Minute

- 3 in 1 Verarbeitung aller gängigen ready-to-use Spritzen, Vials und Karpulen in einer Tub/Nest-Konfiguration

-

Alle gängigen Füllsysteme möglich

-

Standard Begasungs- und Vakuumfunktionen

-

Smartfill für minimalen Produktverlust

-

Manuelles bis vollautomatisches Handling aller Prozesse

-

Automatische In-Prozess-Kontrolle (IPK)

-

Optional: Linienkonfiguration mit 100% In-Prozess-Kontrolle (IPK)

-

Ausführung für Isolatoren, offene und geschlossene RABS-Systeme

Unsere ausgewählten Komplettlösungen zum Füllen und Verschließen von RTU Packmitteln im Nest

Unsere ganzheitlichen Linienkonzepte ersparen Ihnen lange Planungsphasen, denn wir bieten Ihnen eine Komplettlösung für viele Anforderungen.

Das ist der Kern unserer Ready Engineered Philosophie: Anstatt langen Planungs- und Konstruktionsphasen bekommen Sie ein durchdachtes Linienkonzept, welches Ihnen höchste Flexibilität und großen Gestaltungsspielraum lässt. Dafür haben wir unser über Jahrzehnte gesammeltes Know-how über Prozesse und Anlagen gemeinsam mit unseren Partnern in die Konzepte einfließen lassen.

robocell

Handschuhlose Roboteranlage garantiert die höchste Produkt- und Prozesssicherheit.

flexfill

Lösung zur Verarbeitung von Spritzen, Vials und Karpulen genesteter ready-to-use Packmittel.

labworx Serie

groninger Halbautomaten Serie zum Füllen und Verschließen von Spritzen, Vials und Karpulen.