Filling and closing cosmetic products - efficiently, reliably, intuitively and intelligently

Short changeover times for improved line availability. Intuitive operation through an intelligent user interface. Accessible, smart machines. We know what our customers need, consequently, we are able to use our lines efficiently and reliably.

We are constantly working on improving ourselves. This is the reason, why we are not only working continuously on completely new machine concepts, but also revise those machines that have been market leaders for a long time, and sometimes design them from scratch.

This also includes our claim to always work with the latest technologies and applications. The use of 3D printing within the company, is an impressive example of how innovations can help shorten delivery times or even skip entire parts of the supply chain.

Quickconnect

Downtimes of individual machines or entire lines quickly add up: Not only is there less production, as a result, other finely balanced processes may also get confused.

With the groninger Quickconnect technology, the changeover times of a line can be reduced by up to 60%. On the basis of SMED (Single Minute Exchange of Dies) and its optimization approaches, there are numerous ways to accelerate these processes.

This goes beyond a purely tool-free format change; format parts with a plug-in system or automatic height adjustments for work and test stations offer additional options to significantly increase the availability of a line.

We also focus our work on combining as many formats as possible, consequently, only few format parts have to be changed. This also affects the format costs.

And finally, Quickconnect is precisely tailored to the needs of the operating and technical staff. To this end, we did not only continuously optimized the system for our customers, but rather together with them.

Safetransfer

Even if large quantities are processed at high speed, it may not be at the expense of the end product during transport and processing. The groninger Safetransfer process solutions address this challenge in detail.

The goal is to process even the most sensitive item carefully, reliably and quickly.

The high-quality products of our customers must be processed as carefully as possible, even if it has to be fast. It is important to protect them from damage and contamination of any kind, to avoid incorrect filling and sloshing items.

The transport systems in groninger’s portfolio provide intermittent and continuous transport methods - or a combination of both. We also use new drive technologies, for example, transport systems with magnetic levitation technology, servo walking beam, but also new types of vibration drives in the feed. This is how we maximize transport speeds without putting more strain on the items.

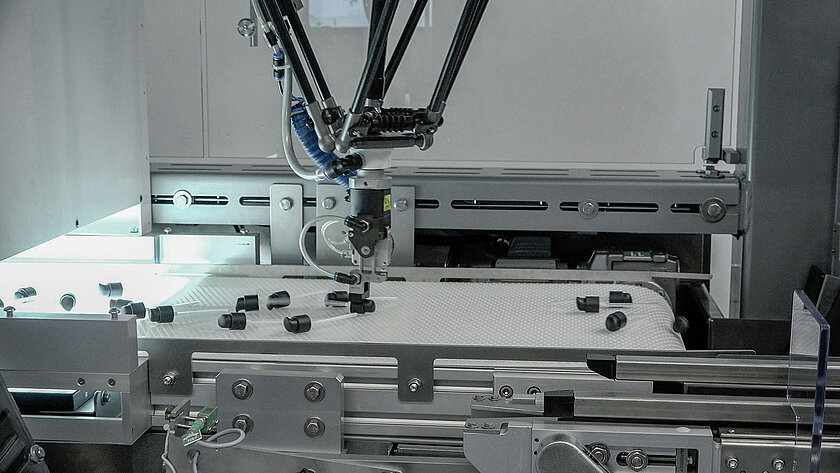

The groninger Safetransfer products also allow for automation and autonomy within the lines. Sorting and feeding units with robot systems ensure a perfect pick & place. As a result, unusual or extremely sensitive items can also be reliably sorted, set up and used.

Smartfill

Product waste caused by unsystematic and inefficient processes is not only uneconomical, but also not sustainable.

We optimized all program steps and product paths for the groninger Smartfill and designed them for maximum efficiency to generate a process that is loss-free as possible. And what if there is still product left in the intermediate container at the end of production and the bottles still have to be run empty? With Smartfill, remaining quantities can also be filled appropriately by counting backwards.

There are neither large losses during the pumping process nor excessive residual quantities in intermediate product containers neither in the filling system after filling.

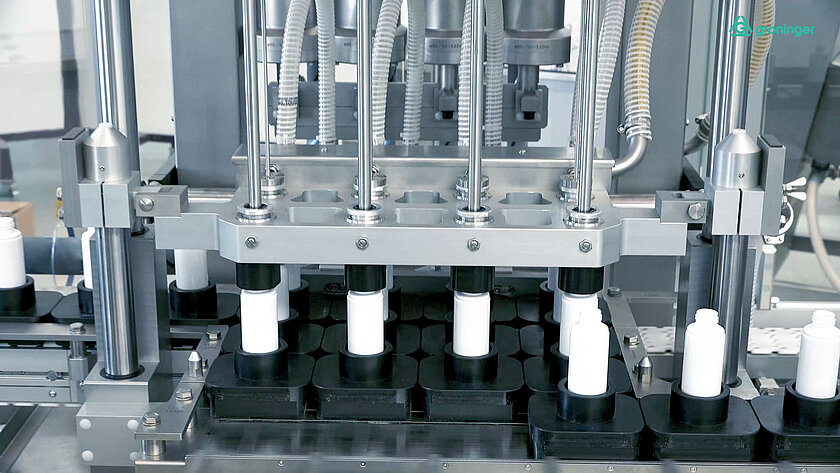

When it comes to filling, we leave nothing to chance. The accuracy of the pumps used by groninger comes very close to perfection. Whether you use our self-made rotary piston pumps, the mass flow meters or peristaltic pumps, we guarantee an impressive filling process across our entire product range.

We offer the right solution for every product! This also includes the groninger filling needles. Regardless of whether you would like to fill a high or low viscosity, oily or sticky product, with the right filling needle (closing on the inside, outside, in the center or open), it can be processed perfectly.

Smarttrack

We rely on future technology, allowing you gain flexibility. With our Smarttrack concept, simple format changes and consistent process optimization become possible. groninger uses our 4 and 6-axis robots for intelligent sorting and feeding of bottles, but also, for example, for closing with screw closures, pumps or mascara brushes. It makes no difference for the sorting and feeding robot whether the items must be placed in transport pucks or directly in or on the feeding tracks.

The use of sorting robots can reduce the number of format parts and changeover times significantly. SmartTrack even makes the fully automated format change with quick-change tools possible. With RFID chips on the tools and a reader on the robot arm, it is always ensured that the robot actually selected the correct format part?

This technology facilitates the processing of unusual, challenging bottle and closure shapes: Complex contours and sensitive surfaces pose no problem for the various vacuum or gripping tools - also even at high speeds.

Fastlane

With the groninger Fastlane we are able to ensure time savings of up to 80% when providing new or additional format sets so that you can react quickly to trends and developments.

How do we make this possible? With the groninger FastLane, we rely on the perfect selection of materials, in-house production and optimized supply chains, but also on the most modern production techniques. 3D printing is playing an increasingly important role for format parts. The various printing processes make it possible to save material and thus also weight. And as a result, creating high strength, stability and resilience of all parts through different infill printing patterns.

We combine more durable format sets for individual requirements on top of significant time savings. The decision for groninger Fastlane is evident.

Combifill

Lines today, should be able to process bottles or creme jars made of different materials. Whether plastic, glass or aluminum - it requires flexibility and variability.

For the groninger Combifill philosophy, we attach great importance to finding the perfect material for all format parts that come into contact with the item, in order to be able to guarantee careful processes for items of all kinds. This is how we expand the range of possibilities for every type of machine.

We use this approach for all processes: For feeding, blowing out and suctioning, transport, but also for centering, filling and closing and many other work steps. There is a tailor-made process for each one, which is perfectly tailored to the respective item and yet remains absolutely flexible.

With groninger Combifill you are not only prepared for the present, but above all for the future.

Additional features for processing cosmetics

-

Optimal operability

Depending on the requirements, groninger machine concepts are designed so that they can only be operated from one side. In this way, they enable an optimized operating concept and minimize the risks for the operator.

-

Highest availability

The greatest possible automation of the production processes enables high availability of the line whenever it is needed.

-

Small number of formats

Through continuous function and process optimization, we were able to reduce the number of required formats by up to 40% compared to conventional filling lines.

-

Scalable output

Do you need to increase production speed? Our scalable line concepts allow for a performance adjustment based on the product requirements.

-

High degree of automation in a small space

Automation and good manufacturing practice also play an important role in research and development. groninger also offers automated solutions for smaller spaces or laboratories.

-

Easy and quick cleaning

We ensure that the pumps are compact, sealless and wear-free--turning the cleaning of the filling equipment into child’s play.