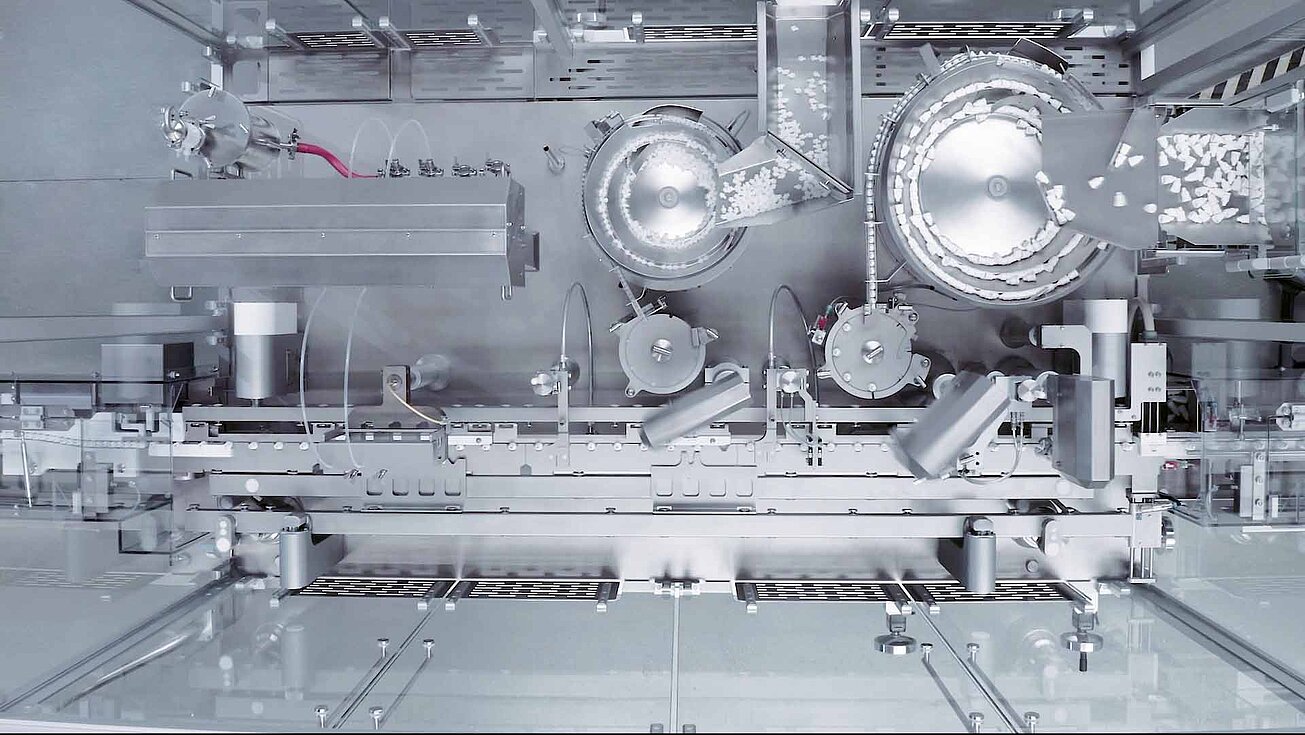

flexcare 10: Filling non-sterile pharma products, diagnostics or dietary supplements? Our new flexcare 10 is the perfect solution for small batches!

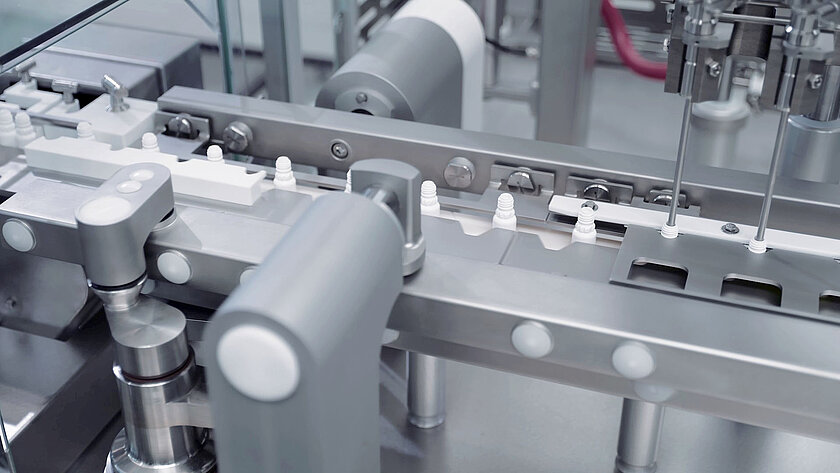

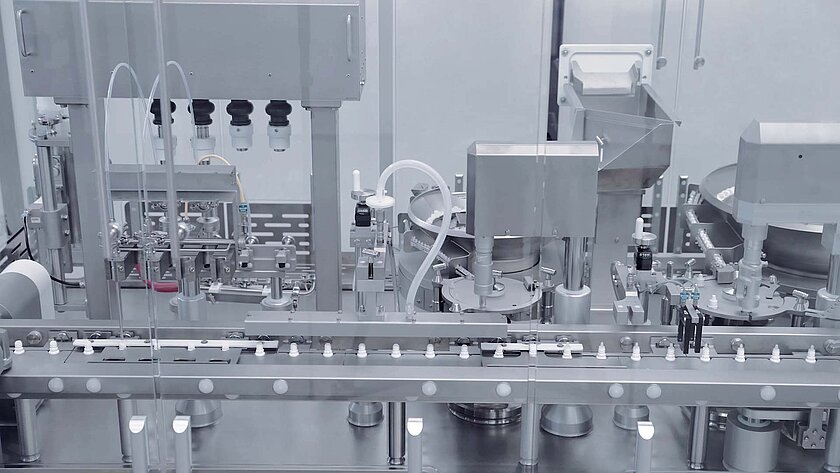

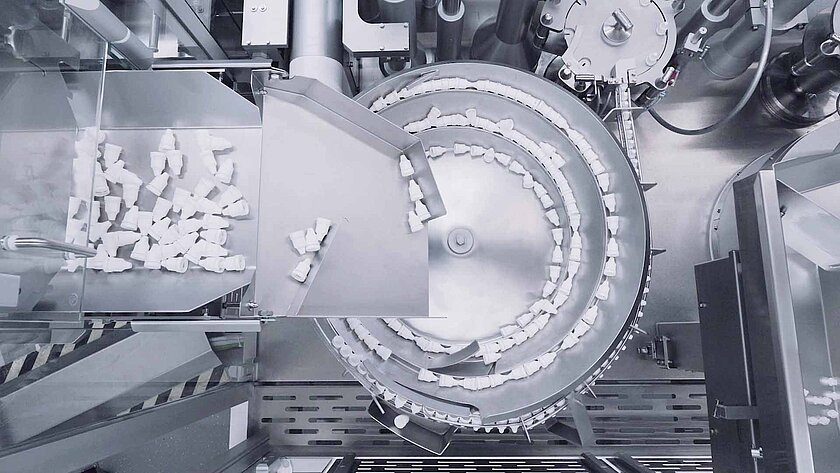

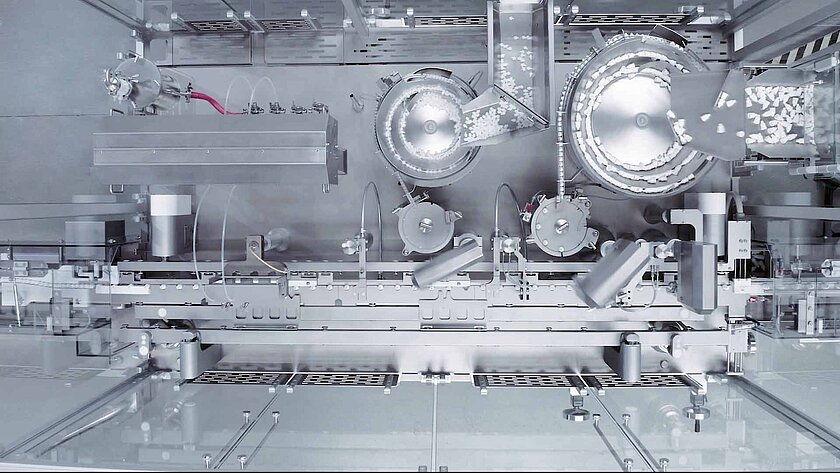

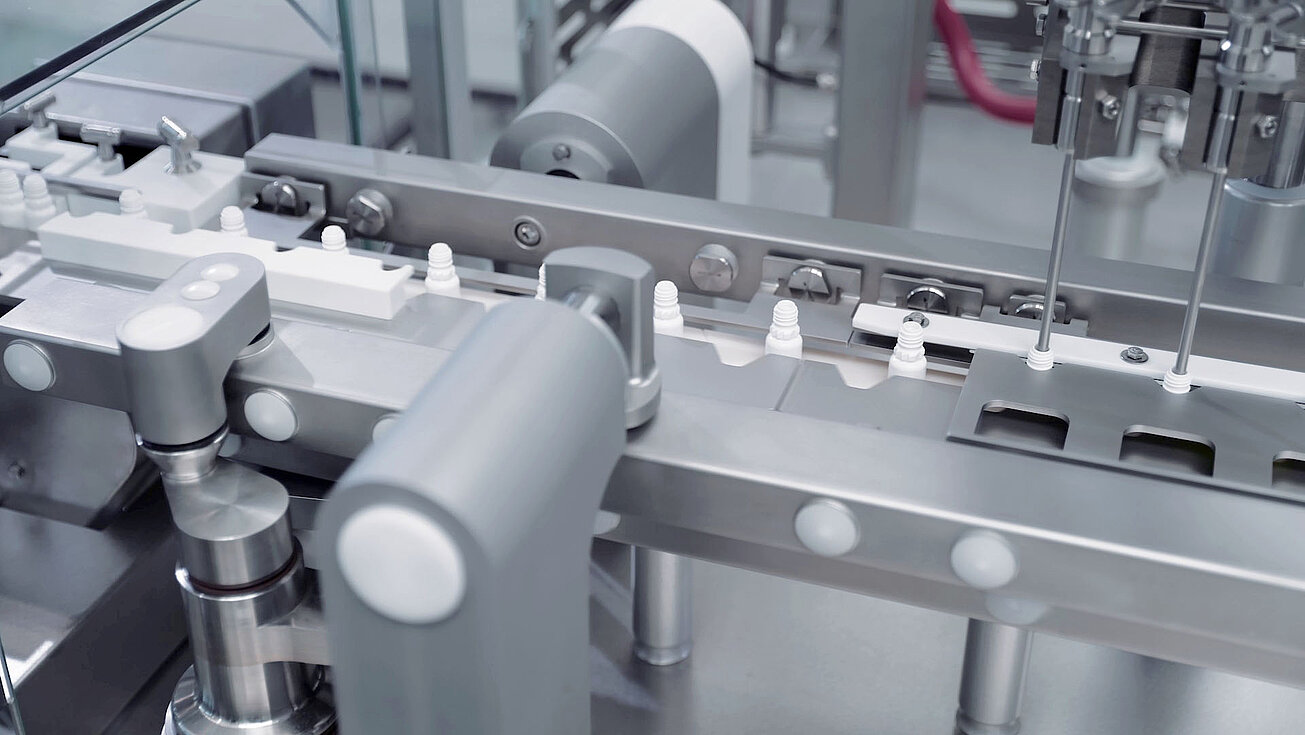

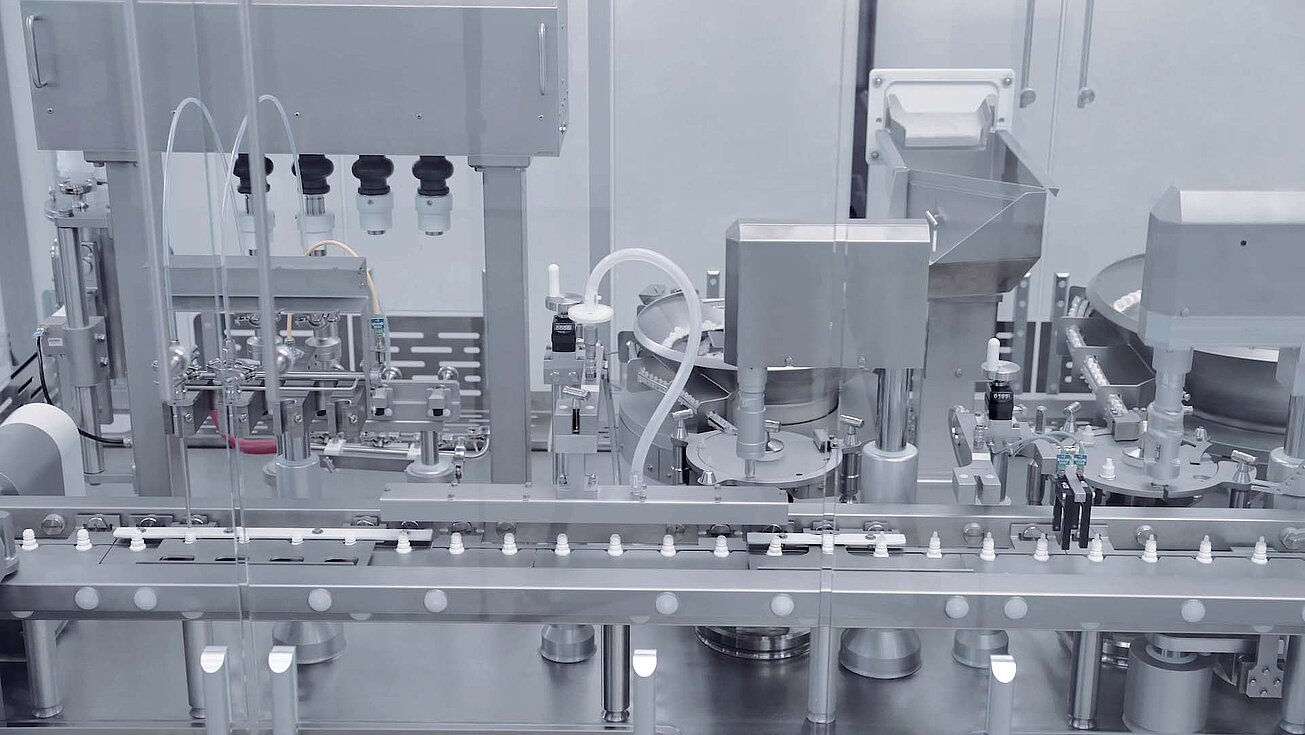

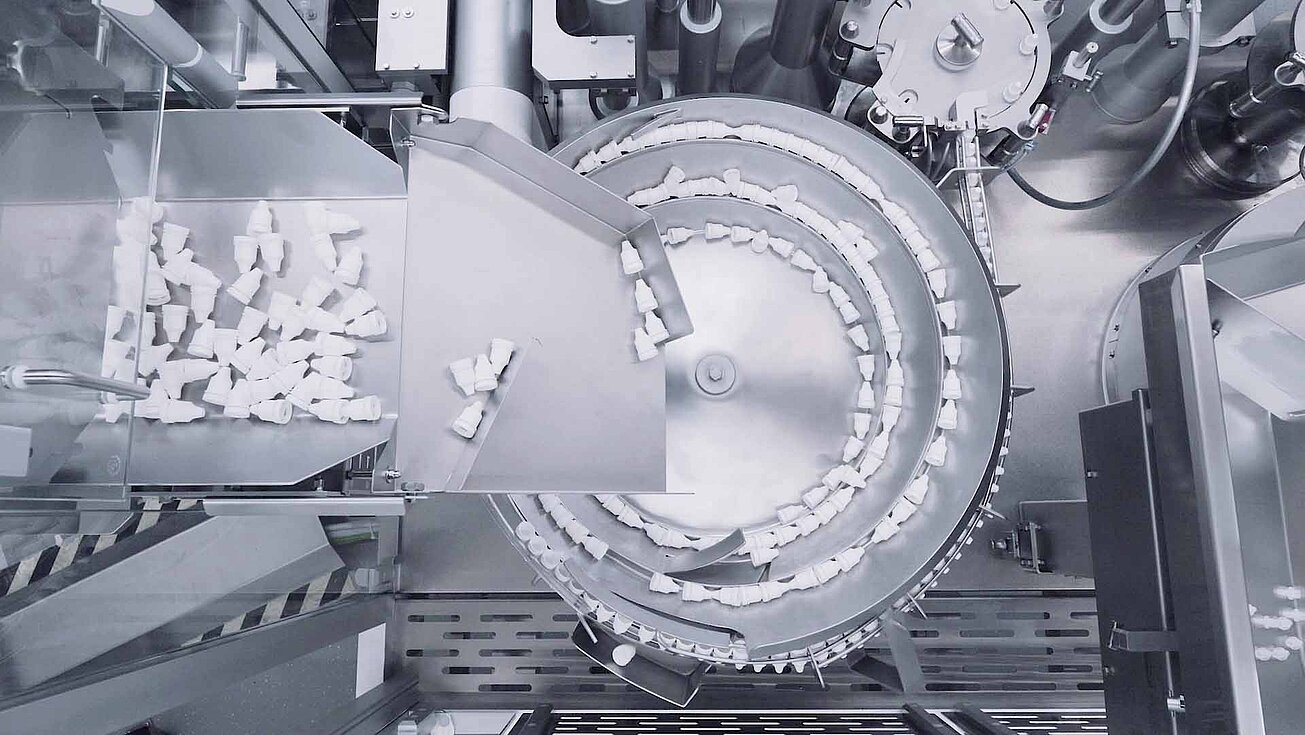

This very compact and flexible machine is ideally suited for the production-safe processing of glass and plastic bottles. Individually adapted to your requirements, a wide variety of machine functions can be implemented on this system, including pre- and post-gassing, filling, insertion of droppers and spray pumps, crimping, and torque-monitored pre- and post-screwing with servomotors. Batch and audit trail protocols can be implemented flexibly and easily. Tool-free format part changeover can be performed quickly and easily due to the compact system design, resulting in high flexibility and system availability.

Highlights of the flexcare 10

- Very compact system with low personnel and space requirements

- Multifunctional machine simplifi es production

- Reduced investment for faster return on investment

More information on our flexcare 10

flexcare 10: Filling and closing machine for consumer healthcare products

Features

For small and medium filling volumes

Filling and sealing of glass and plastic objects at a speed of up to 70 objects per minute.

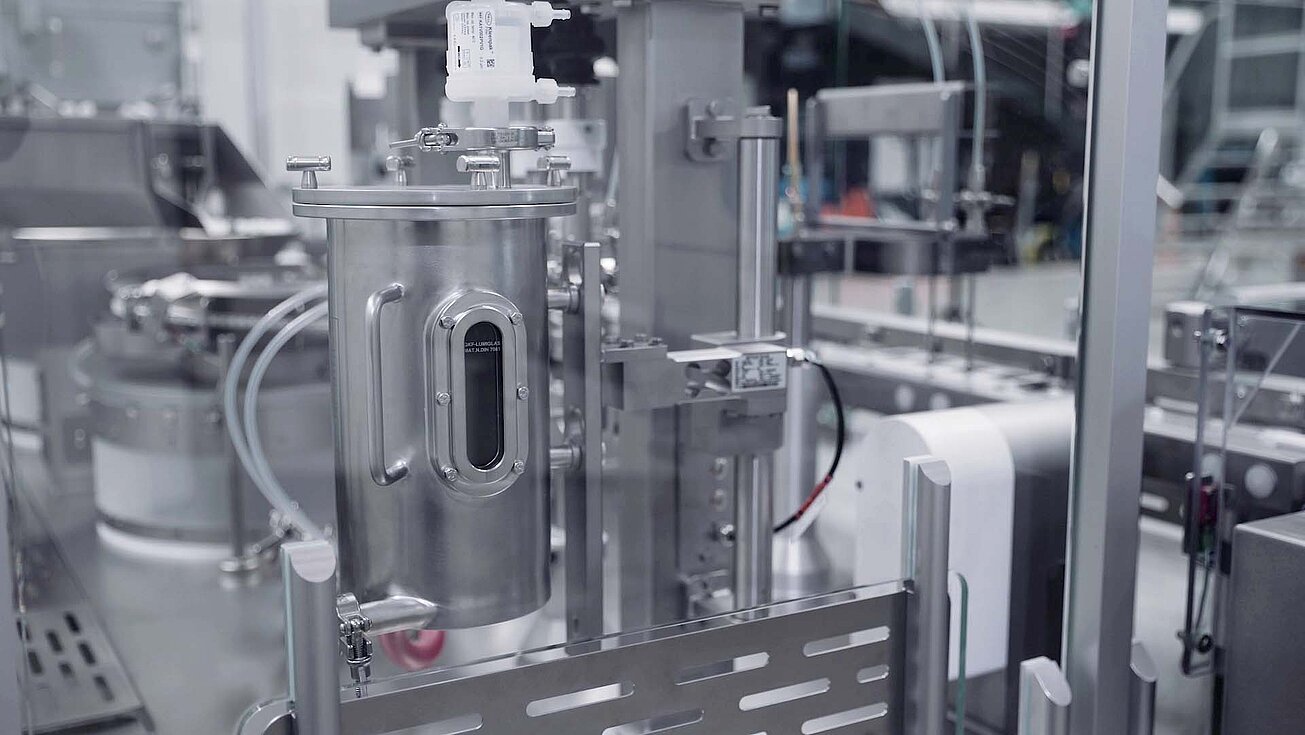

All common filling systems

The filling station of our flexcare machine is so flexibly designed that all common filling systems can be used. Which one you want to use can depend entirely on the product to be processed. For example, we work with volumetric rotary piston pumps made of stainless steel for manual cleaning or also with peristaltic pumps.

GMP friendly and LF compliant design

The machine complies with GMP requirements and impresses with its compact design. There is also the option of attaching a laminar flow.

In-process control of the filling weight

The objects are stably transported through the plant with transport rakes; this makes it easy to implement fully automatic weight control.

Specifications

- Filling systems: rotary piston pump (RKP) or peristaltic pump (PP)

- Closing with up to 2 components