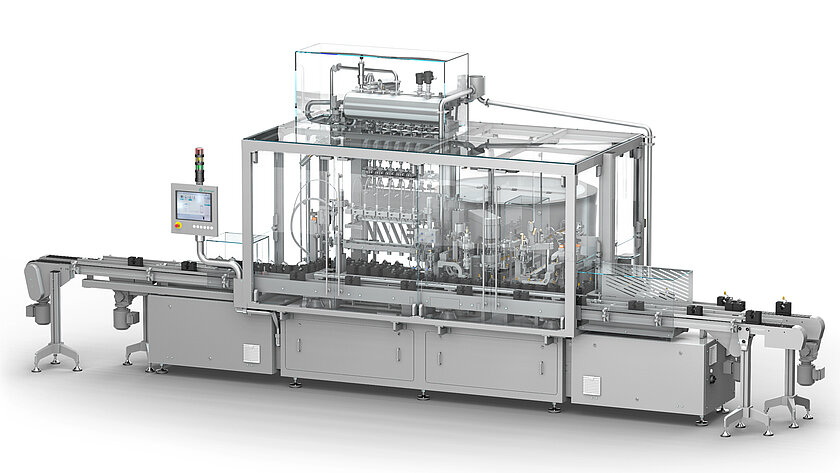

Perfume Filling Machine: fragrance 50

The groninger fragrance 50 is a highly efficient automatic perfume filling machine that is part of the ready engineered series. It is specifically designed to fill liquid cosmetic products such as perfume, aftershave, and eau de toilette at a remarkable speed of up to 50 bottles per minute. This makes it a top choice for companies that require a fast and reliable filling process.

When it comes to cosmetic production, flexibility is a crucial factor in choosing a filling line. The groninger fragrance 50 offers unparalleled flexibility and infinite possibilities. You can either start with the full equipment offered or opt for a less extensive configuration, depending on your needs. Additionally, you can expand and modify the filler at any time in the future, giving you maximum flexibility and security right from the start. Apart from the filling and capping machine, groninger, as a manufacturer of filling machines with many years of experience, also provides labeling and robotic solutions.

With the groninger fragrance 50, the company is setting new standards and breaking new ground. The machine is a game-changer in the perfume filling industry, and it offers numerous advantages for filling perfume. The groninger fragrance 50 is a reliable, high-speed, and flexible machine that guarantees maximum efficiency and productivity. So, if you're looking for a top-of-the-line perfume filling solution, the groninger fragrance 50 is a perfect choice.

fragrance 50 highlights

-

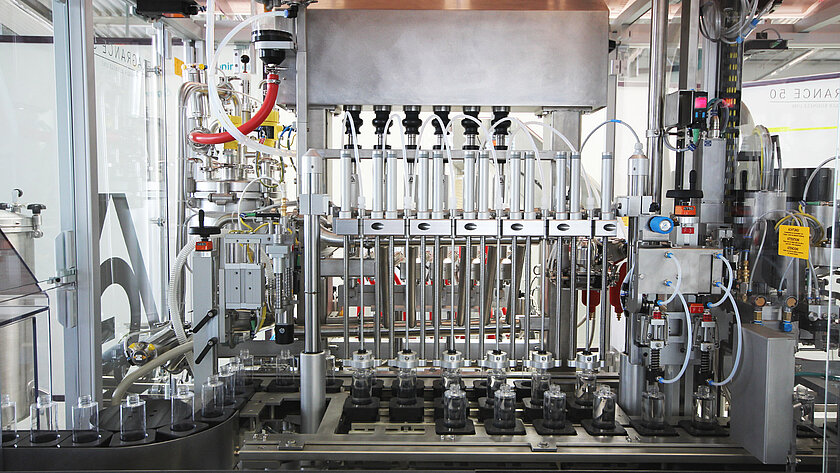

Crimping station with integrated quality control

Spray pumps - as they are used for perfumes - are sealed tightly with the bottle using a crimp station.

-

Several test stations

In order to be able to process different dip tubes correctly, we use the corresponding test stations. Sensors or camera systems check whether the dip tube is there prior to inserting it into the bottle.

-

Different filling systems

No matter what your filling needs are, the filling station has got you covered. With a range of options available, from fully automated systems to manual implementations, you can customize your filling and cleaning process based on your unique requirements. This flexibility ensures that you can fill a variety of products with ease, whether it's thick creams or light liquids. Plus, with the ability to choose between different filling systems, you can ensure that your filling station is optimized for your specific use case. So whether you're filling bottles for your small business or running a large-scale production line, the filling station has the versatility you need to get the job done right.

-

Walking beam transport

When transporting glass or plastic objects through the machine, a walking beam transport is used. When you are changing the format, you will only have to change the transport puck, this allows you to process many different products without the effort becoming too great.

-

Filling level regulation

To ensure a consistent filling level in each item, it's recommended to introduce a filling level regulation option. This involves filling the bottle slightly above capacity and then extracting the excess content at a specified and uniform level. This guarantees a visually identical filling level in every item.

-

Different closure options

The versatility of the system is truly impressive. Depending on the specific needs of your operation, it can handle either crimp or screw closures with ease. This means you won't have to worry about investing in separate equipment for each type of closure, saving you both time and money. Plus, with the system's reliable and efficient performance, you can be sure that each closure will be processed with precision and consistency. No matter what type of closure you use, this system has got you covered.

fragrance 50 advantages

- High machine availability and productivity

- Highest process reliability with precise filling process control

- Flexible and format-independent: Handles a wide variety of objects, including unusual bottle designs

- Can be used for small and large production batches

- Compact design with little space requirement

- Integrated control cabinets

- Easy to relocate

- Fully CIP capable

- Low product loss during filling and format change

- Ideal accessibility to the units