Cooperation between Civica, SKAN and groninger

Addressing healthcare challenges in the US

Access to essential medications, particularly life-saving drugs like insulin, remains a significant challenge in the American healthcare landscape. Vital medications often hover beyond reach due to exorbitant prices and persistent scarcities. Civica's “reason why” for their foundation in 2018 is clear: to confront these challenges directly by producing generic sterile injectables that are consistently in short supply and offering others at low, sustainable prices.

„We don’t believe people should have to choose between food, rent and their insulin.“ (Ned McCoy, Civica’s CEO)

Collaborating with hospitals, health systems, and philanthropies, Civica ensures reliable access to quality medications for patients across the US. From addressing shortages in hospitals to tackling the insulin crisis, Civica's dedication to its mission is truly inspiring.

As of March 2024, Civica was already able to provide 160 million doses of generic medications, enough to help treat 70 million patients. With their new, state-of-the-art Virginia facility, Civica will continue to grow exponentially the numbers of patients they help serve by providing quality, essential medicines for years to come.

Crossing borders, bridging gaps

Disrupting the pharmaceutical status quo demands collective action. Civica understands the value of trusted and experienced partners who share their vision of enhancing and safeguarding lives. As the establishment of the Virginia plant was a greenfield project, expertise and professional advice was even more crucial for success. The partnership between Civica, groninger, and SKAN transcends geographical boundaries, merging diverse perspectives and skills to achieve optimal outcomes.

Of course, some challenges had to be mastered together. Essential requirements for the project were:

- Short lead times to expedite production startup and facility opening,

- Cost-consciousness due to non-profit business model, without compromising on quality,

- Strong local support, necessitating reliable partners for format parts, service, and other needs,

- Compliance with US market requirements,

- Flexibility and adaptable solutions for frequent format and product changes.

groninger and SKAN have been working together for decades, which facilitates project management and communication enormously. groninger's expertise in both nest and bulk processing in combination with SKAN’s leading isolator technology streamlined the project process, ensuring efficient execution. Both groninger’s and SKAN’s support extended beyond technological functionality, encompassing workflow design and operational optimization. Despite common disruptions in supply chains of recent years, the collaboration ensured timely delivery and seamless coordination.

Technical Details

Formats and Output

Vial filling line

-

Output: 400 vials/min (24.000 vials/h)

-

Processing range of the vials: 2R-50H

Nest filling line

-

Output: 240 syringes/min (14,000 syringes/h)

-

Processing range of the syringes: 1ml long, 1ml short, 2.25 ml

Line Configuration

Vial filling line:

- Rotary vial washer with infeed turntable

- Row x row sterilization tunnel infeed pusher

- Hot air sterilization tunnel

- Buffer turntable and transition to intermitted transport system

- SKAN isolator (over filling machine)

- Transport via adjustable walking beam for multiple vial sizes

- 100% IPC

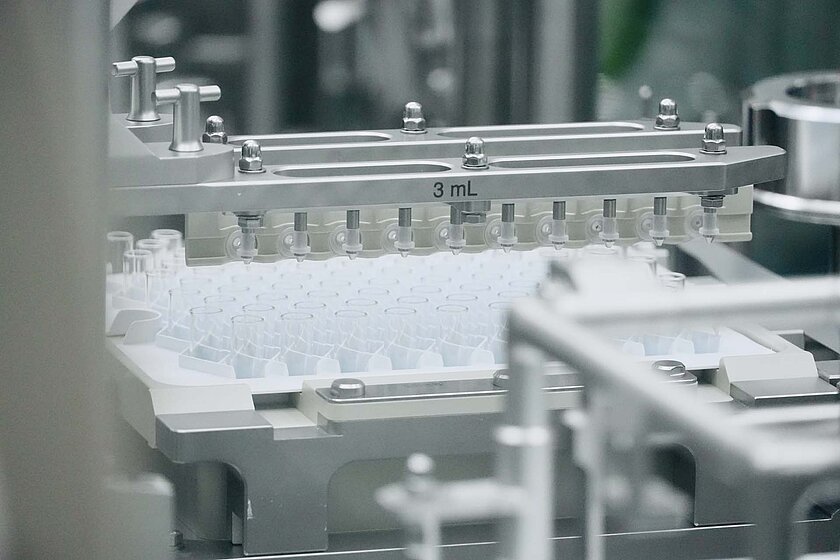

- 8-headed filling system with peristaltic pumps

- Single-use filling path

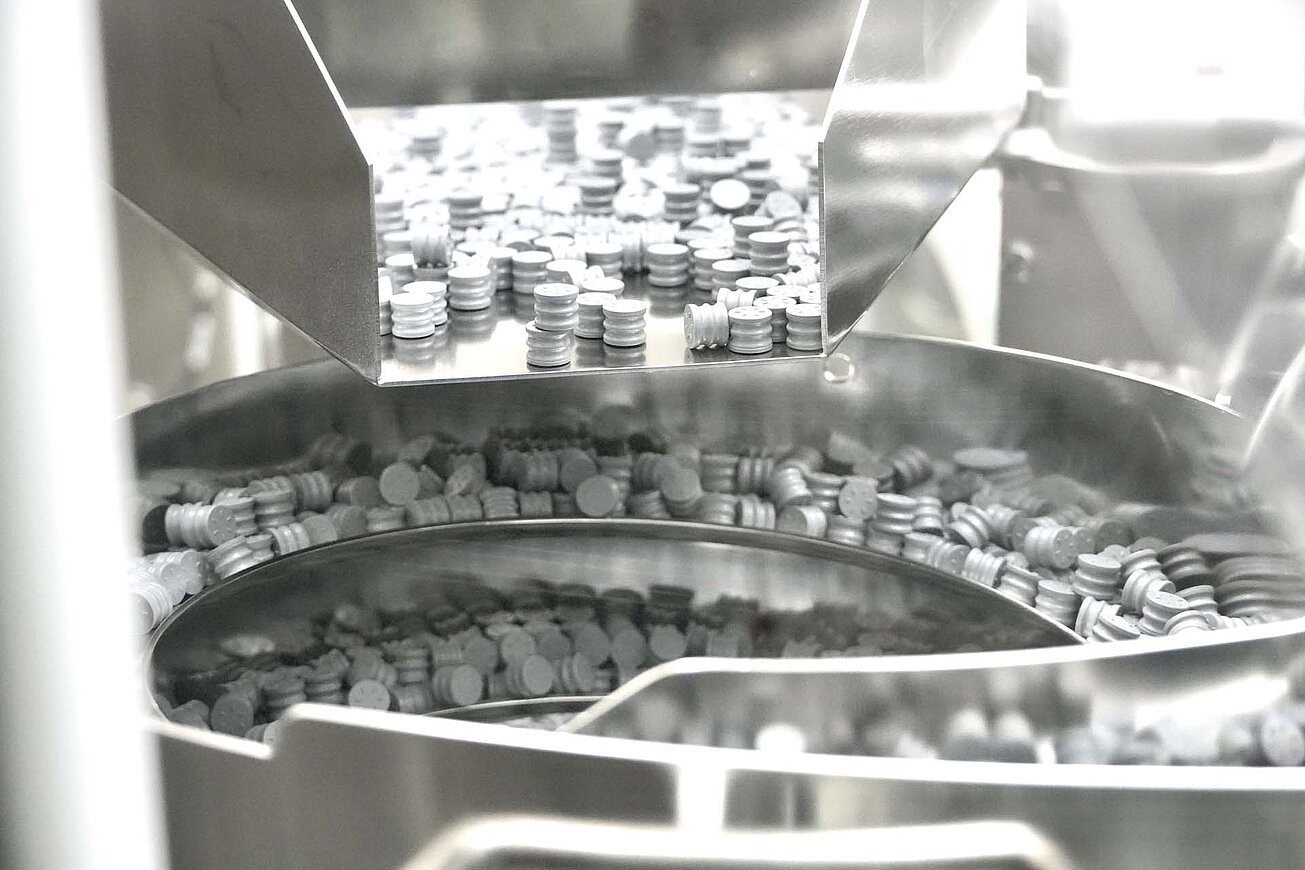

- Stopper introduction via transfer system from ATEC

- 8-headed stoppering station

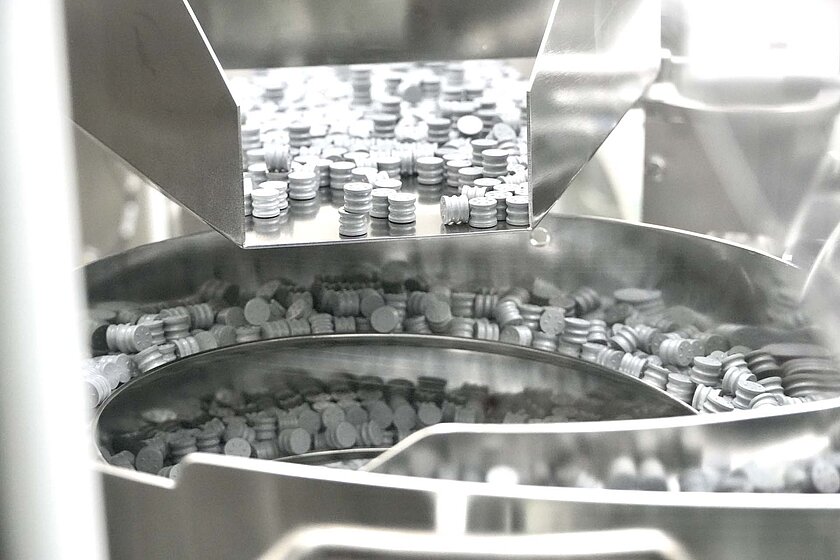

- 8-headed capping machine under active oRABS

- Inkjet printer for vial coding

- Check station for print on vial via camera system

- Tray-off in double magazine

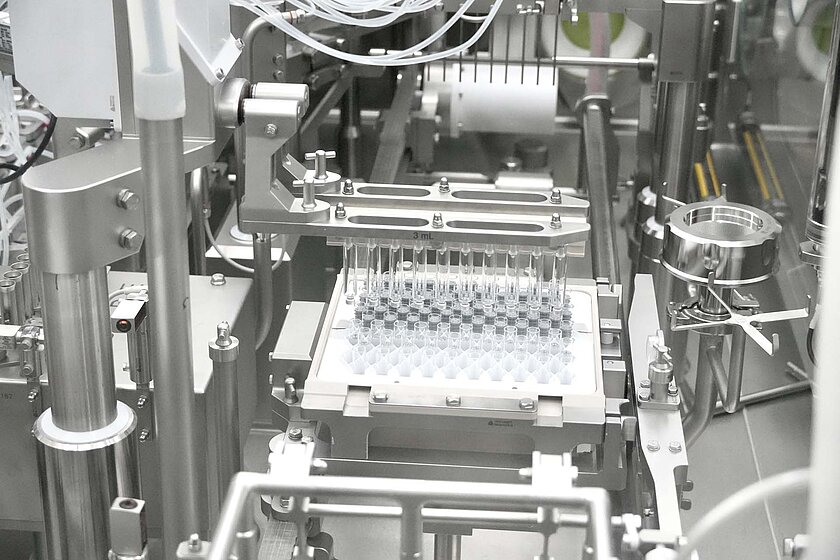

Nest filling line:

- Manual bag opener

- Fully automatic bag stretcher

- No-touch transfer (NTT) (fully automated)

- Delid and deliner

- SKAN isolator (over filling machine)

- Nest filling with statistical IPC

- 10-headed filling system with peristaltic pumps

- Single-use filling path

- Stopper infeed via transfer system from ATEC

- 5-lane stoppering unit with 10-digit stopper set

- Nest

Pioneering technological solutions

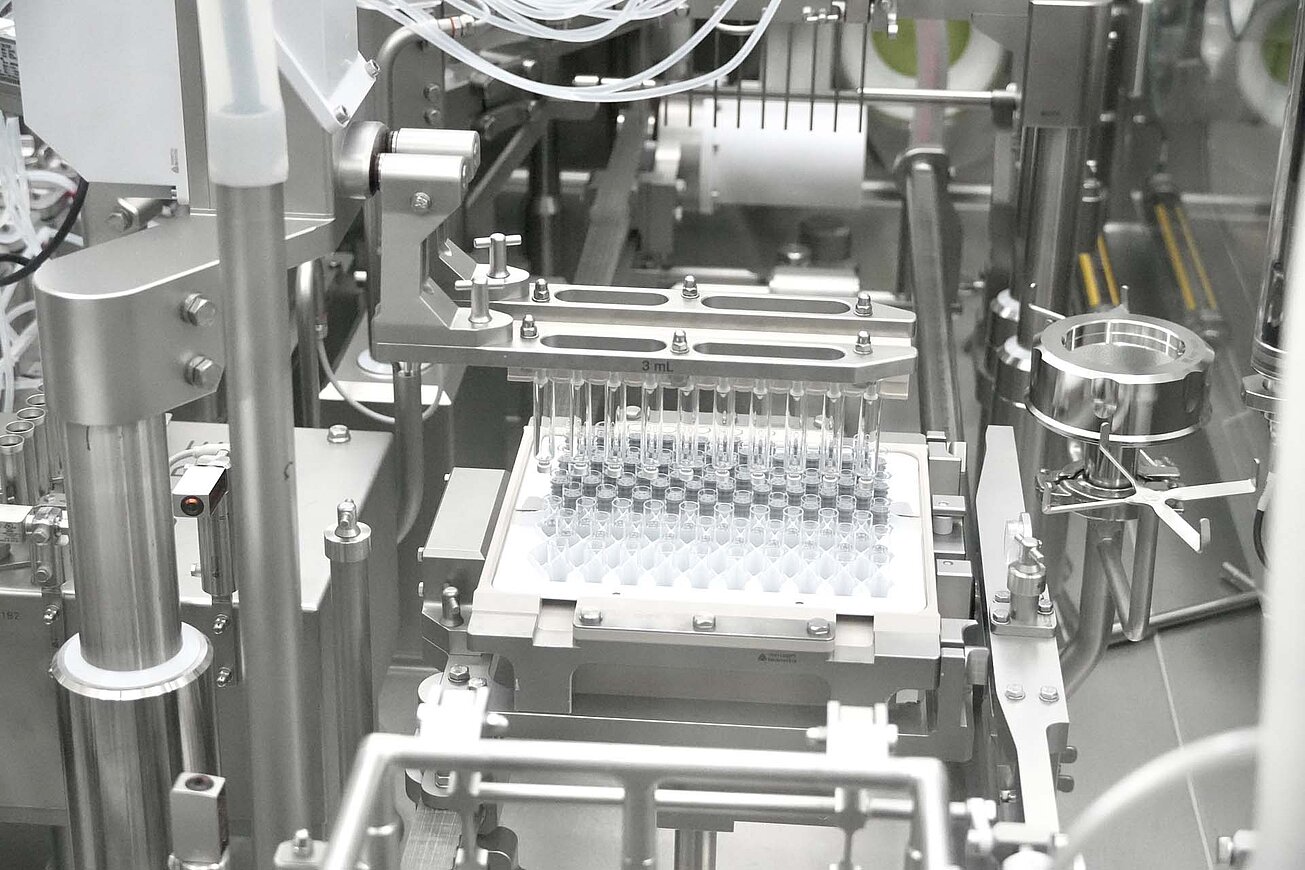

Civica's initiative is backed by the best-in-class technology from groninger + SKAN. The project comprises one vial filling line, known as integra, and one nest filling solution. Civica chose these technological solutions for their reliability, adaptability, and forward-thinking design.

As the product portfolio at Civica was not finalized at time of order, adaptable solutions were key. The integra concept was jointly developed by groninger + SKAN to meet this market demand, with quick changeover times and other smart features to increase flexibility in production.

Another need for flexibility was given in terms of different packaging formats. This is why Civica complemented their machinery with a groninger + SKAN nest filling line for processing ready-to-use formats like syringes and cartridges. Like this, Civica is ideally prepared for the future.

These proven solutions by groninger + SKAN enable Civica to reach high outputs and respectively low prices, while securing the best product quality for patients.

Together always one step ahead

“Together always one step ahead” perfectly sums up this outstanding project, both in terms of partnership and best-in-class technological solutions. The collaboration between Civica, groninger, and SKAN exemplifies the power of collaboration, innovation, and dedication to a shared vision.

And the result of this collaboration is simply amazing: Empowering lives by reshaping the pharmaceutical landscape is not a dream anymore, but the reality for millions of people in the US.

groninger + SKAN: the best of two worlds

Solutions as if from a single source

The long-standing partnership between groninger and SKAN is characterized by reliability, trust, and innovative strength. groninger as an experienced expert for filling solutions and SKAN as the industry leader for cleanroom technology and isolators complement each other perfectly.

integra machine concept

integra - as the name already suggests - stands for the best possible integration, especially for isolator filling lines. Together with SKAN, groninger has developed an advanced, modular machine concept that combines the expertise of both companies.

Through the strong partnership between groninger and SKAN, customers such as Civica Rx benefit twice over, since not only is the product optimally integrated, but project development is also simplified significantly.