About WAGENER & CO. GmbH

WAGENER & CO. GmbH was founded in 1964 as an owner-managed contract manufacturer for semi-solid, liquid and powder formed pharmaceutical products, medicine, cosmetics as well as foodstuffs. Apart from the manufacturing license for pharmaceutical products WAGENER also maintains certifications for medicine products (ISO 13485), for cosmetics (ISO 22716 and IFS HPC) as well as for natural cosmetics. Being a full-service contract manufacturer, they secretly and quietly produce the high quality products of well-known brands by order. Apart from filling, WAGENER also offers all other supply chain process steps, from product development up to the market launch, corresponding their promise, SIMPLY PERFORMANCE.

The project

We delivered the line within eleven months, significantly faster as the agreed delivery time of 12 to 13 months. WAGENER expressed their trust in us with a special statement: An order in a “double pack”.

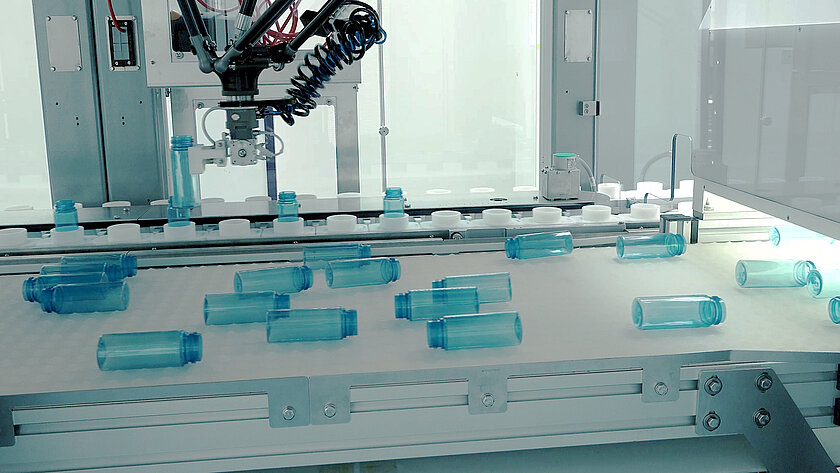

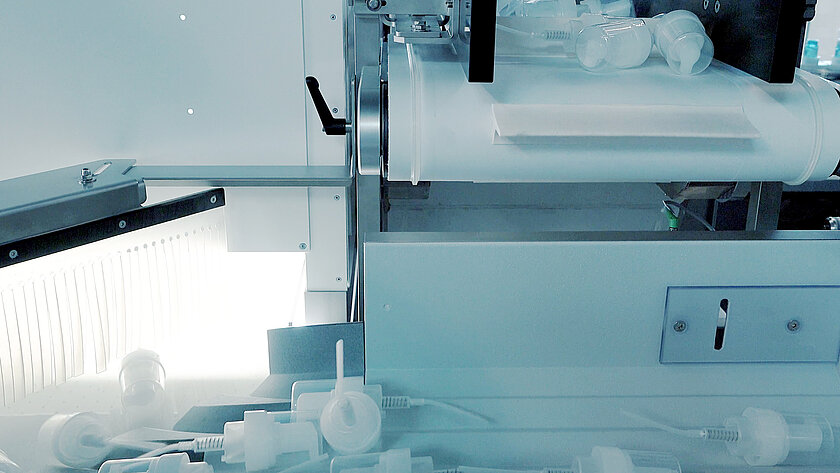

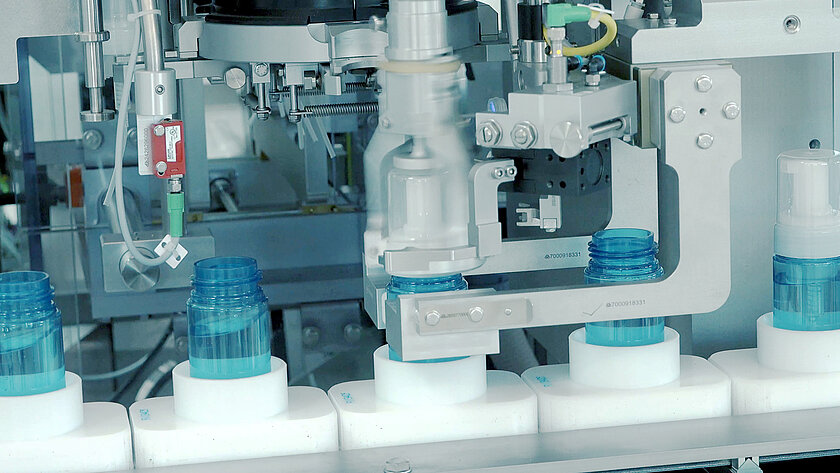

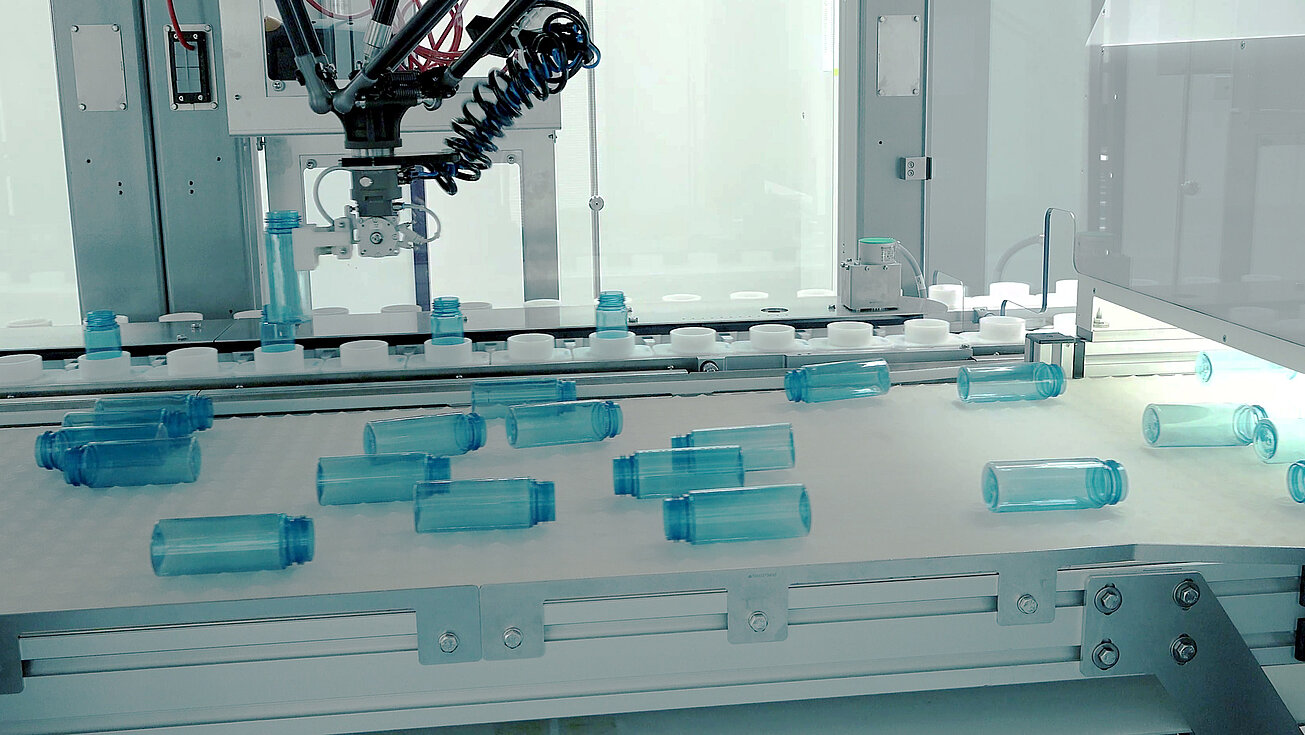

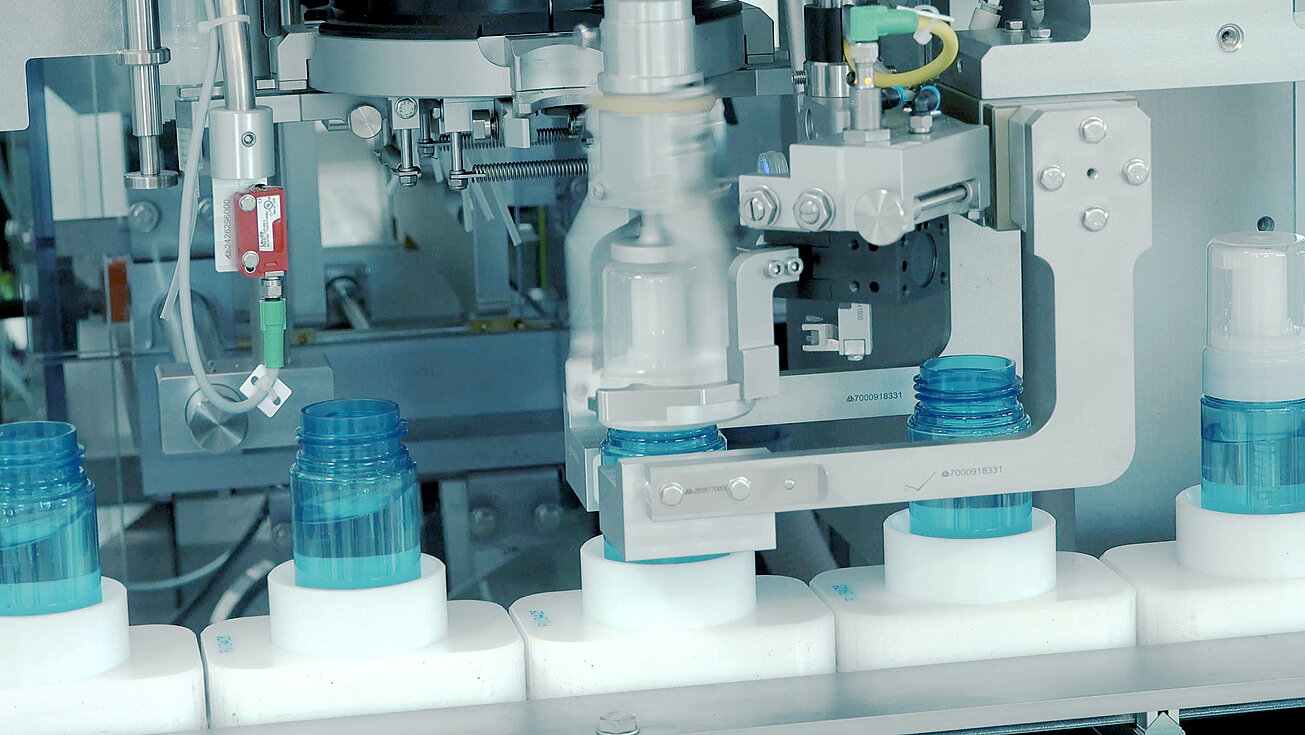

We were also able to complete the CHC line ordered at the same time and deliver it on time. We delivered already a similar line five years prior to that, but for the new order we once again focused on flexibility: The closure feeds are now carried out through robotics, this allows to change to new items much faster.

“groninger always meets the ever-increasing demands. We appreciate the mutual trust and our many years of cooperation as colleagues. We know what we get from groninger: robust, stable running lines, which are ideally suited to our requirements as a contract filler. “ Markus Wagener.

We look forward to continuing to trustfully work with WAGENER!

The solutions

It is very important to us to respond specifically to our clients’ requirements and to offer them the right solutions for their problems.

For WAGENER we were able to score with proven groninger features:

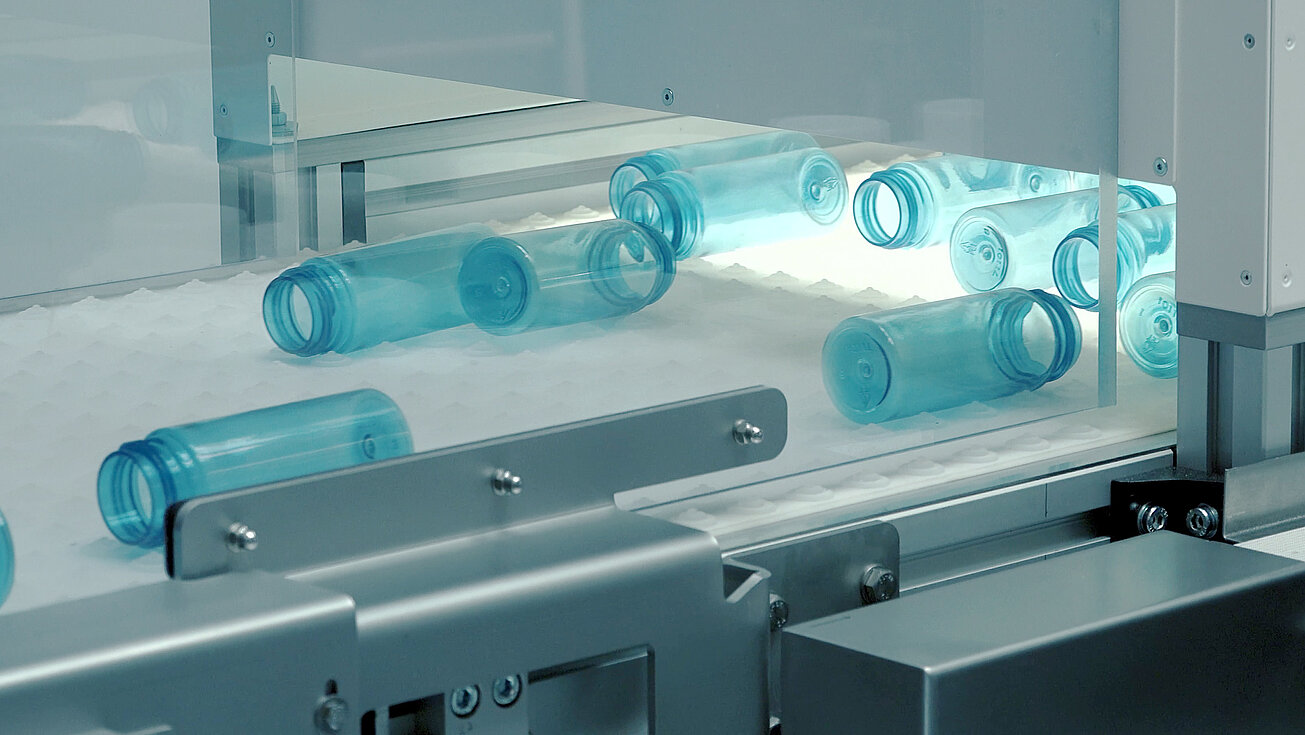

- Our quickconnect technology enables easy, guided and tool-free changeovers with time savings of up to 60%.

- combifill allows WAGENER to be flexible: The technology makes it possible to process a wide variety of products flexibly, consequently, reducing not only time but also costs.

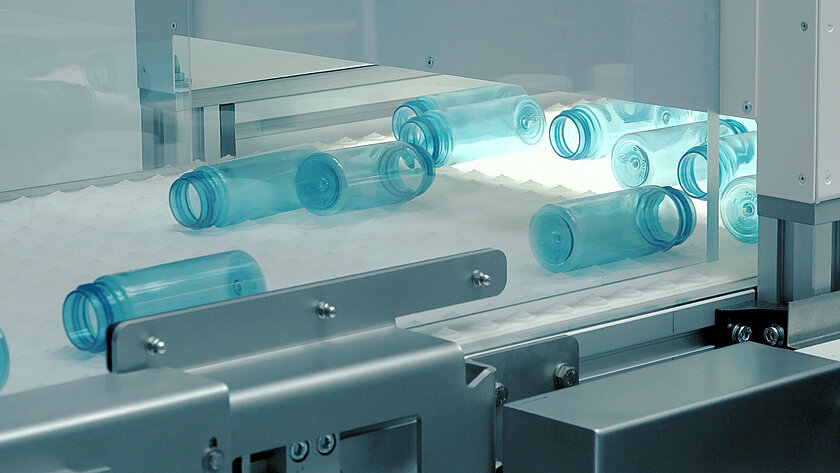

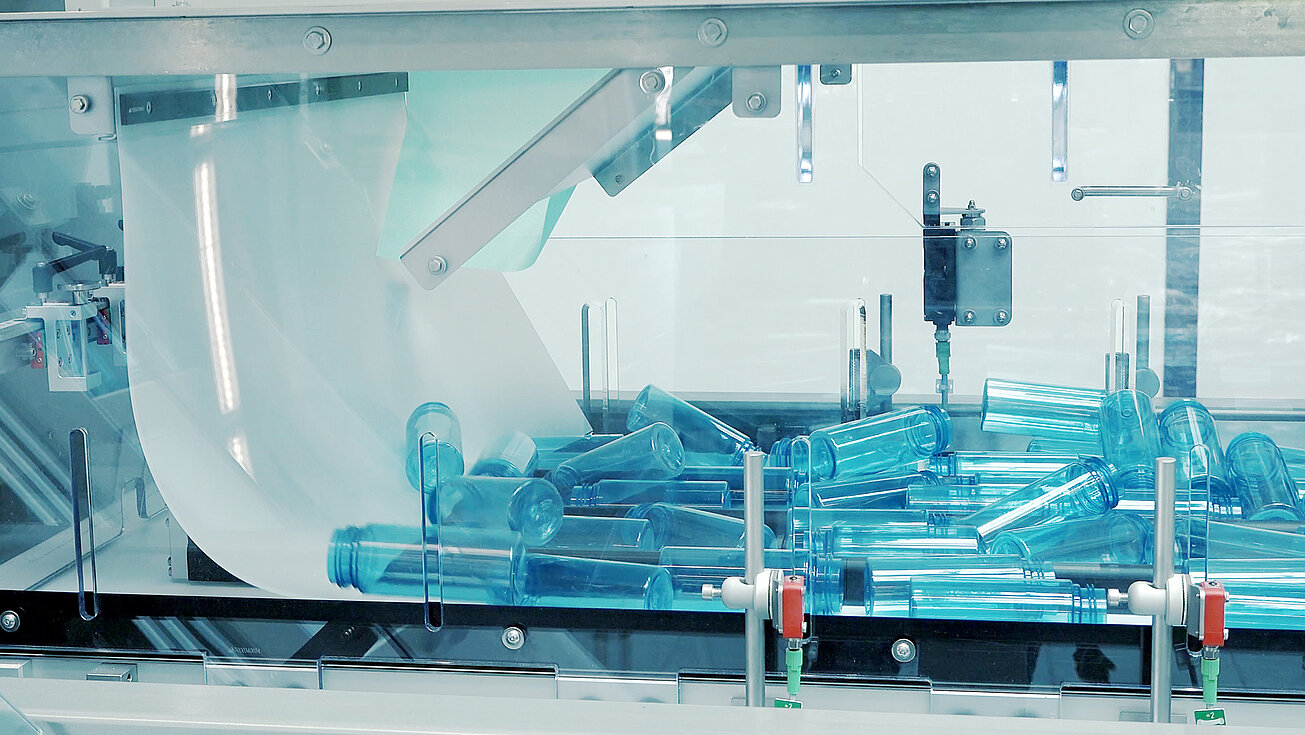

In the future, the entire line will be able to process almost all relevant formats in the field of filling cosmetic products. Depending on the container’s diameter, the filling system used (filling volumes between 5 and 1,000 ml are feasible) and the number of closures, the machine is capable of achieving a production output of up to 120 products per minute.

“We look very much forward to offering this unique combination of flexibility and quality to our well-known customers in future.” Jan-Hendrik Wagener, Sales and Marketing Director at WAGENER & CO. GmbH.

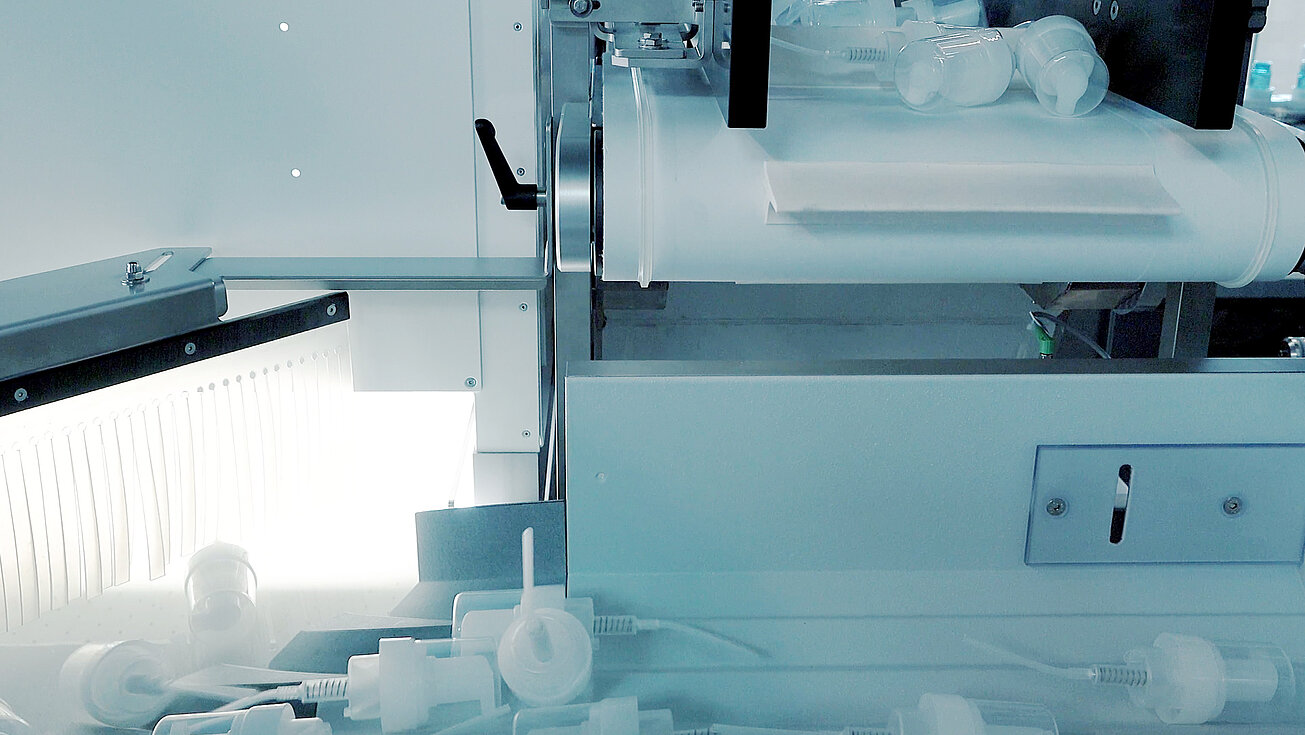

Our groninger line was initially supplied with a set of format parts to fill cleaning foam. Should production change to another product, the customer should be able to very flexibly install his own format parts on the line.

Highlights

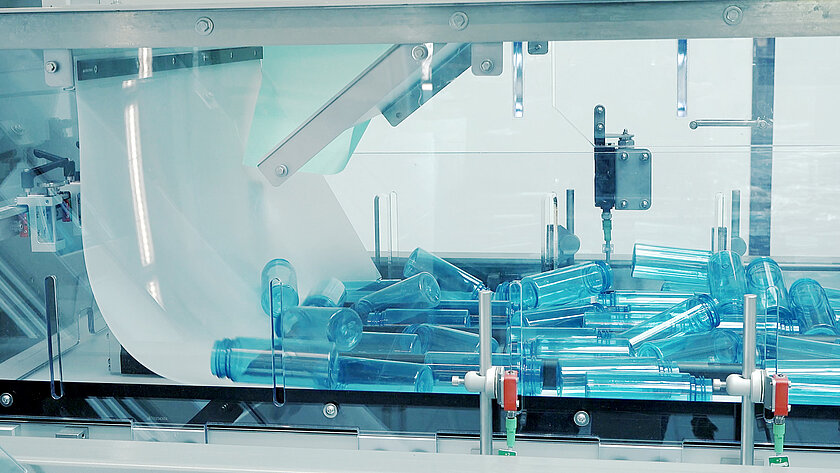

Maximum flexibility, faster response times, lower format part costs and easy changeover: These are essential aspects that speak for the use of our proven robotics to sort closures. Depending on line setup, it is possible to process up to two different closure components, e.g., a pump, a dispenser, a screw closure or a cap. The material supply bunkers were arranged in such a way that they can be filled easily and ergonomically.