Press Releases

groninger at Interpack 2023

What do filling and closing machines for the pharmaceutical, consumer healthcare and cosmetics industries have in common?

The requirements for flexibility, coupled with maximum efficiency and safety, have increased significantly in recent years and continue to rise steadily.

The world market leader for filling and capping machines will be demonstrating how groninger implements these requirements technically and thus offers its customers suitable solutions, among other things, at this year's Interpack in Düsseldorf on more than 400 square meters in Hall 16, Booth A38.

"We are delighted to be returning to Düsseldorf for Interpack after a required break of more than six years and to be presenting our latest technologies from groninger," says Managing Director Jens Groninger, summing up the entire team's anticipation.

The family-owned company has a whole range of innovative solutions in its backpack, with a clear focus on the needs of pharmaceutical, consumer healthcare and cosmetics customers.

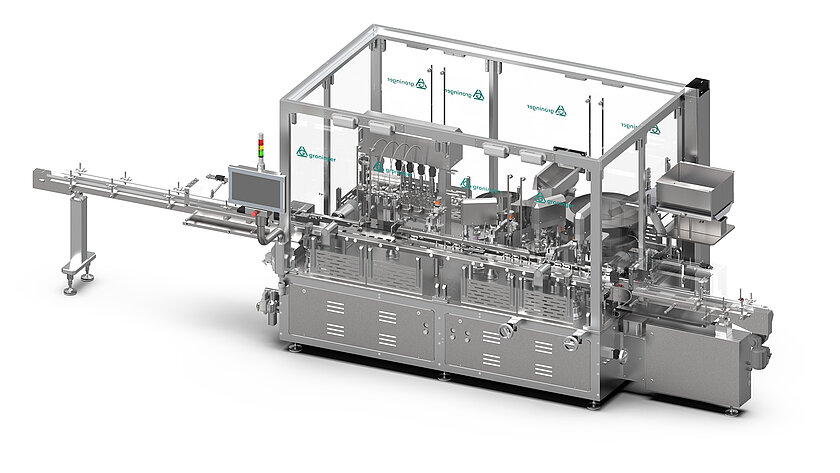

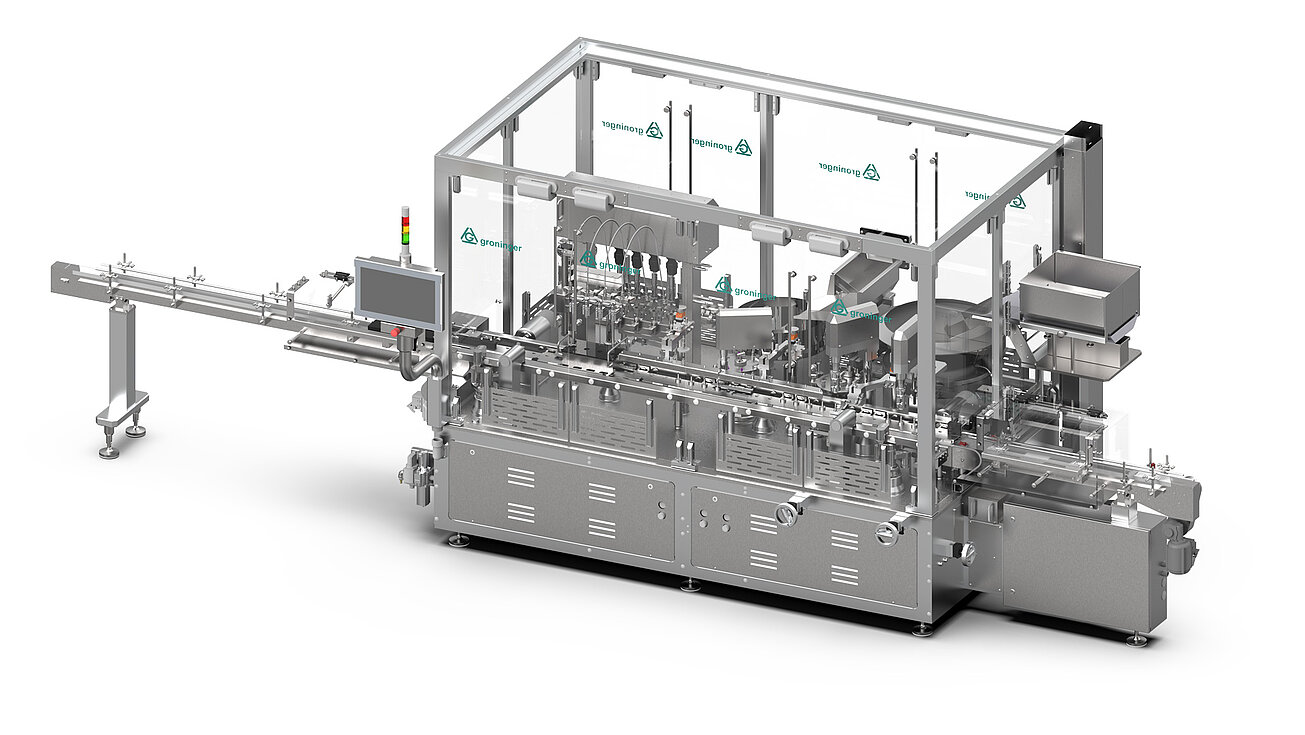

In the consumer healthcare sector, groninger will be exhibiting a flexcare 10 on which, among other things, the processing of OTC products, diagnostics or dietary supplements is possible. "The design standard for this machine is enormously high. Here, where necessary and appropriate, we have transferred the know-how from the sterile or aseptic world to a non-sterile environment," emphasizes Otto Helmle, Sales Manager Consumer Healthcare and Cosmetics. He adds, "With this machine concept, we meet the maximum requirements of the industry to process non-sterile products safely and efficiently, but just as flexibly."

To avoid longer changeover times on the line, the transport of objects through the machine was designed in such a way that only two format sets are required for an object diameter range of 16 to 60 millimeters. The rest are flexibly adapted.

"In this way, we can assure our customers of high machine availability, which they can use for their production process. They simply save on machine downtime thanks to this flexibility from groninger and have valuable production time available instead," Helmle summarizes the advantages for the customer.

The filling volume can be determined just as flexibly: fill volumes from 0.1 to 400 milliliters are possible on the flexcare 10.

However, it is not only the consumer healthcare industry that is experiencing rapid change, accompanied by increased requirements. This development is also noticeable in the other business areas in which groninger is active. "Our customers - regardless of the markets in which they are active - are facing growing challenges. In cosmetics, for example, it is the diversification of products and formats. In the pharmaceutical sector, in addition to flexibility, it is above all the ever-increasing safety requirements for processing pharmaceutical products in an aseptic or sterile environment," says Jens Groninger.

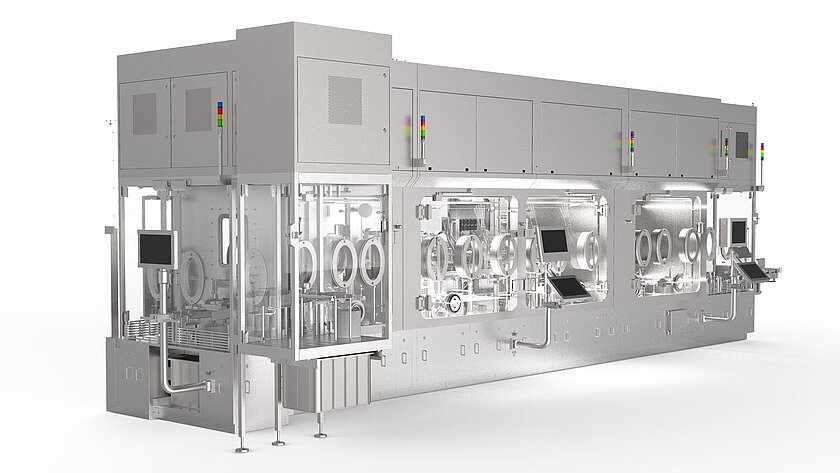

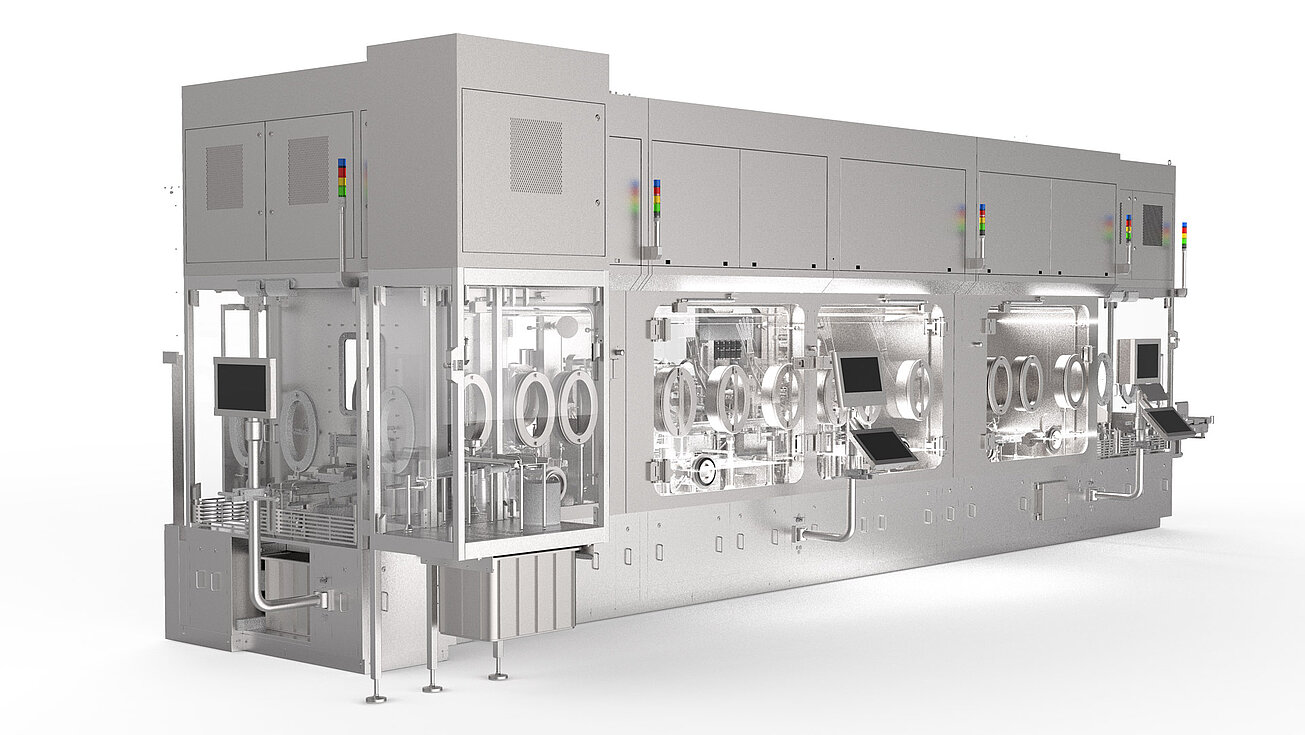

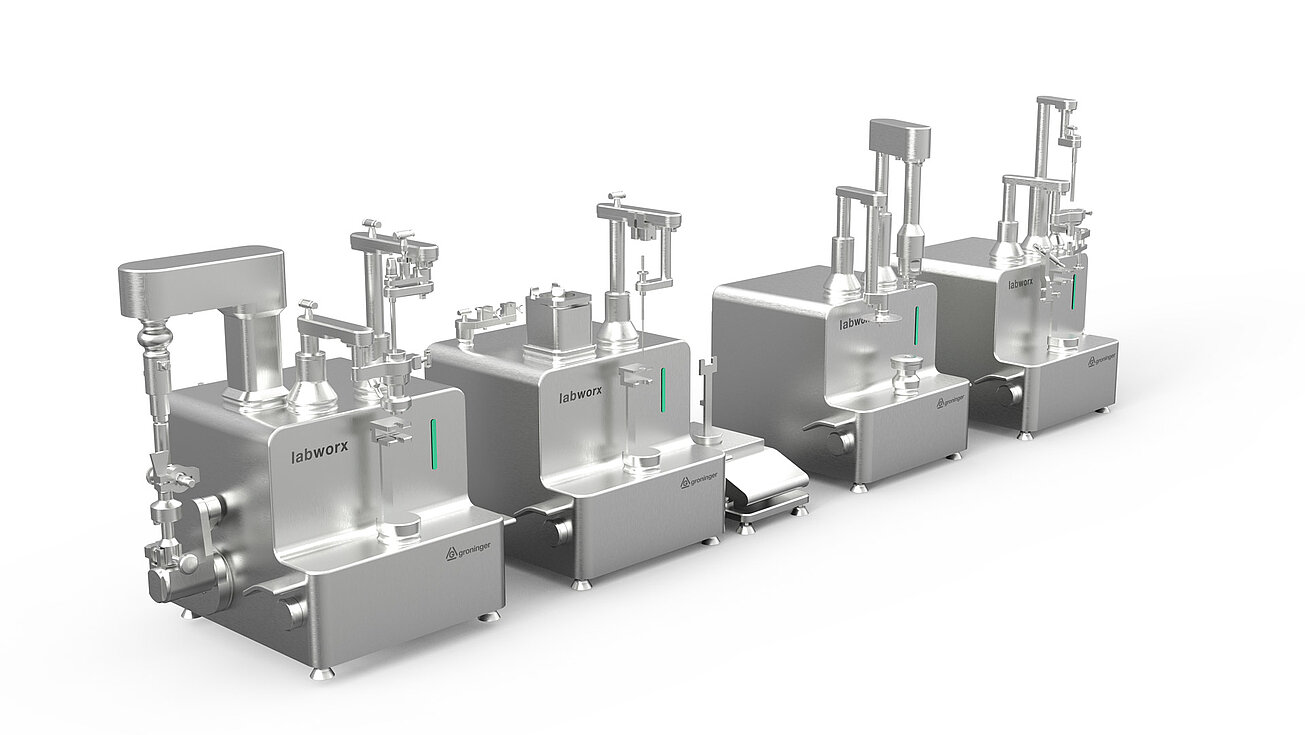

The fact that groninger has the right solutions ready for these requirements is demonstrated by the flexfill line that the machine builder is exhibiting.

"We are relying here on a modular design that can be expanded in various ways - depending on customer requirements," says Dirk Schuster, director of pharmaceutical sales, describing the system concept behind the flexfill.

Thanks to the preconfigured, modular approach, almost innumerable possibilities can be mapped in the processing operations.

"The big advantage with this machine platform is that we don't always have to reinvent the wheel. Our customers can draw on our expertise in mechanical engineering and benefit from the knowledge we have accumulated over 43 years." The result: shorter times to the start of production and thus faster availability of the product on the market - keyword time-to-market.

"This not only benefits our customers, but ultimately also the patients who depend on the pharmaceuticals," explains Jens Groninger. The Corona pandemic clearly demonstrated how important a stable supply of medicines is. "Thanks in part to machines like our flexfill, we can meet these challenges."

For groninger, participation in Interpack is therefore also an important opportunity to strengthen its position as a leading supplier of filling and capping systems and to increase its presence on the global market. Visitors to the trade show can look forward to an exciting program and interesting discussions with groninger's experts.

![[Translate to English:] groninger interpack](/fileadmin/_processed_/0/7/csm_groninger_interpack_neu_a709f21665.jpg)