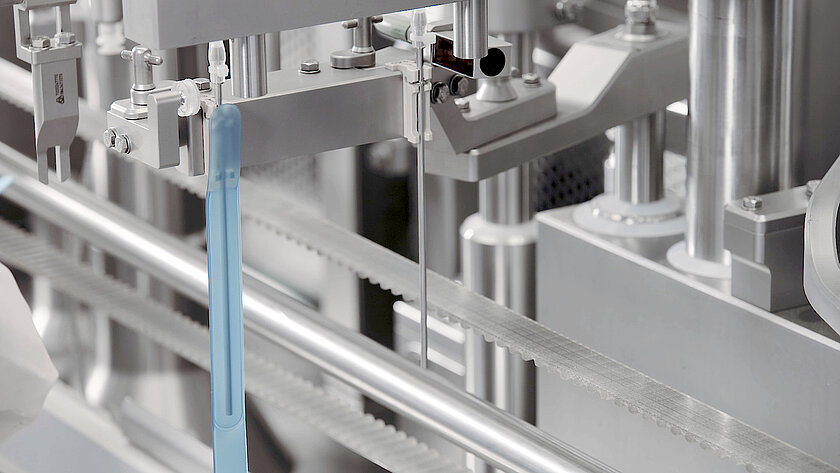

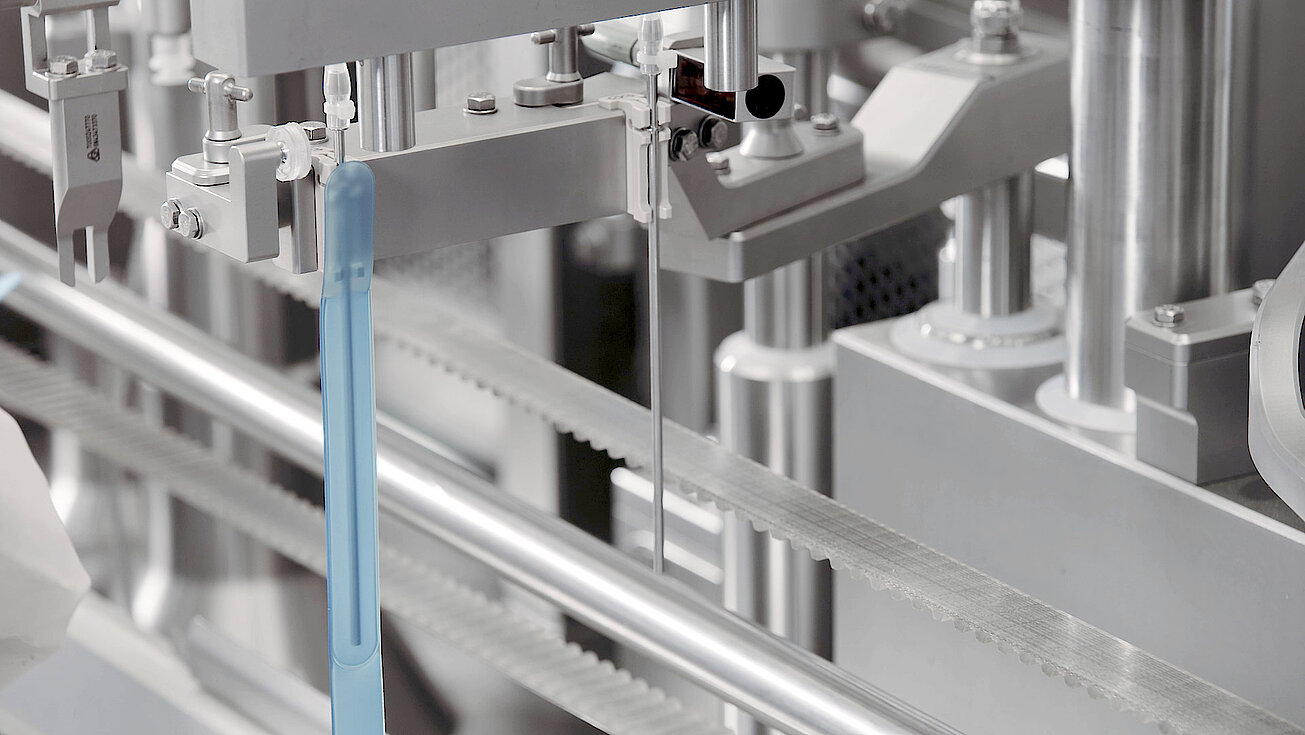

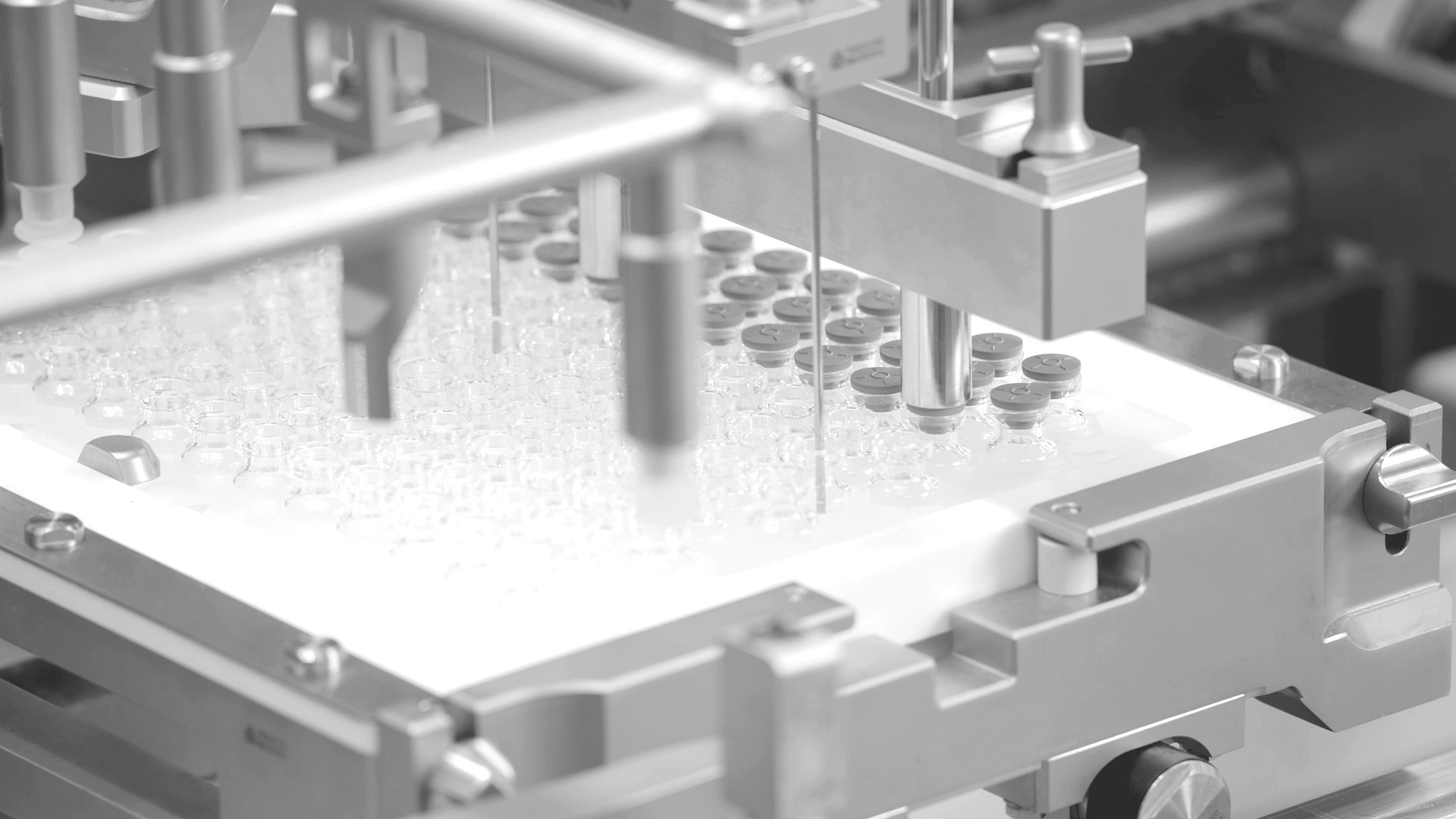

Single-Use Filling Needles

Increase production while reducing risk and utility consumption

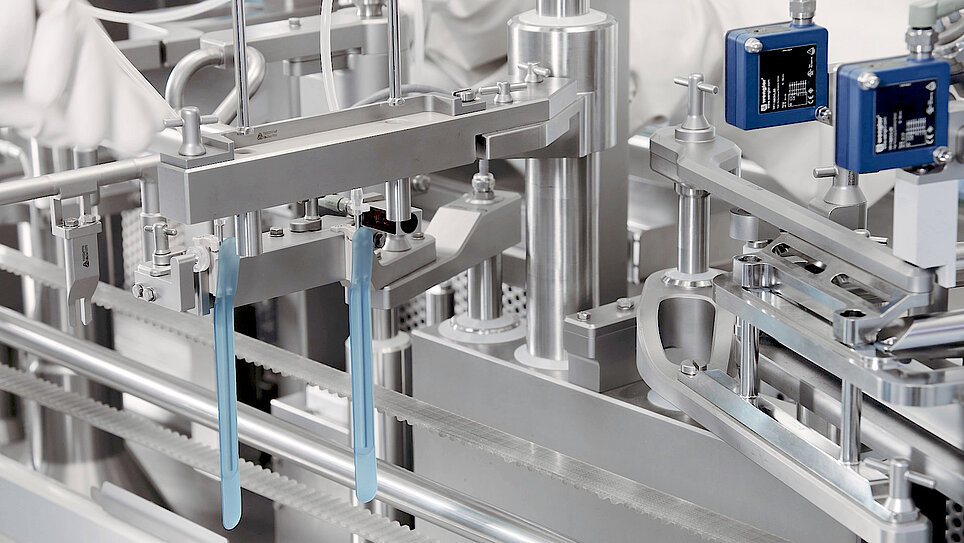

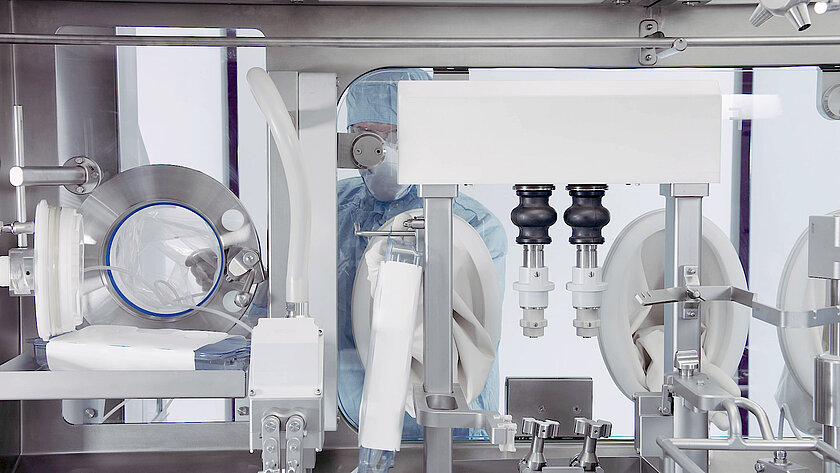

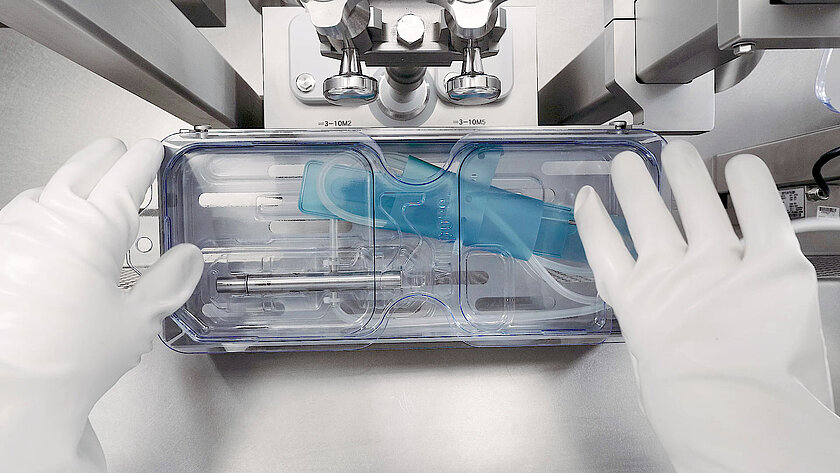

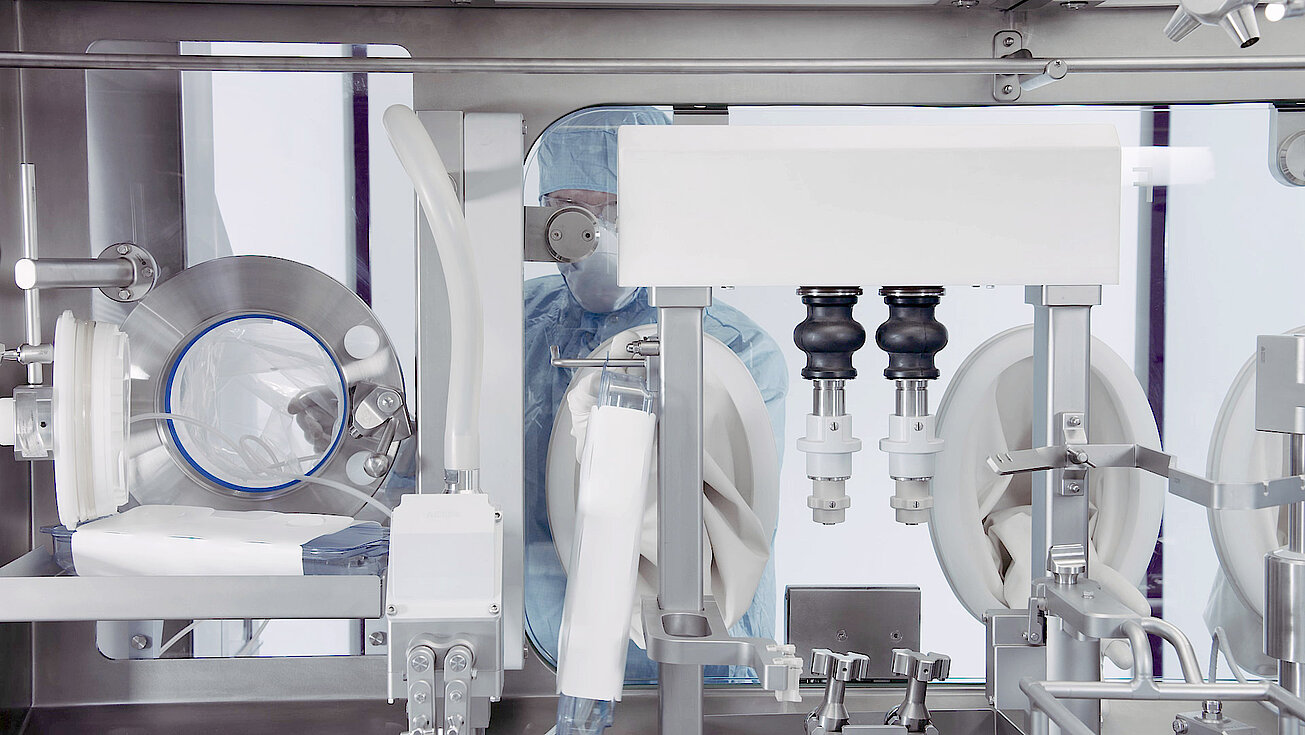

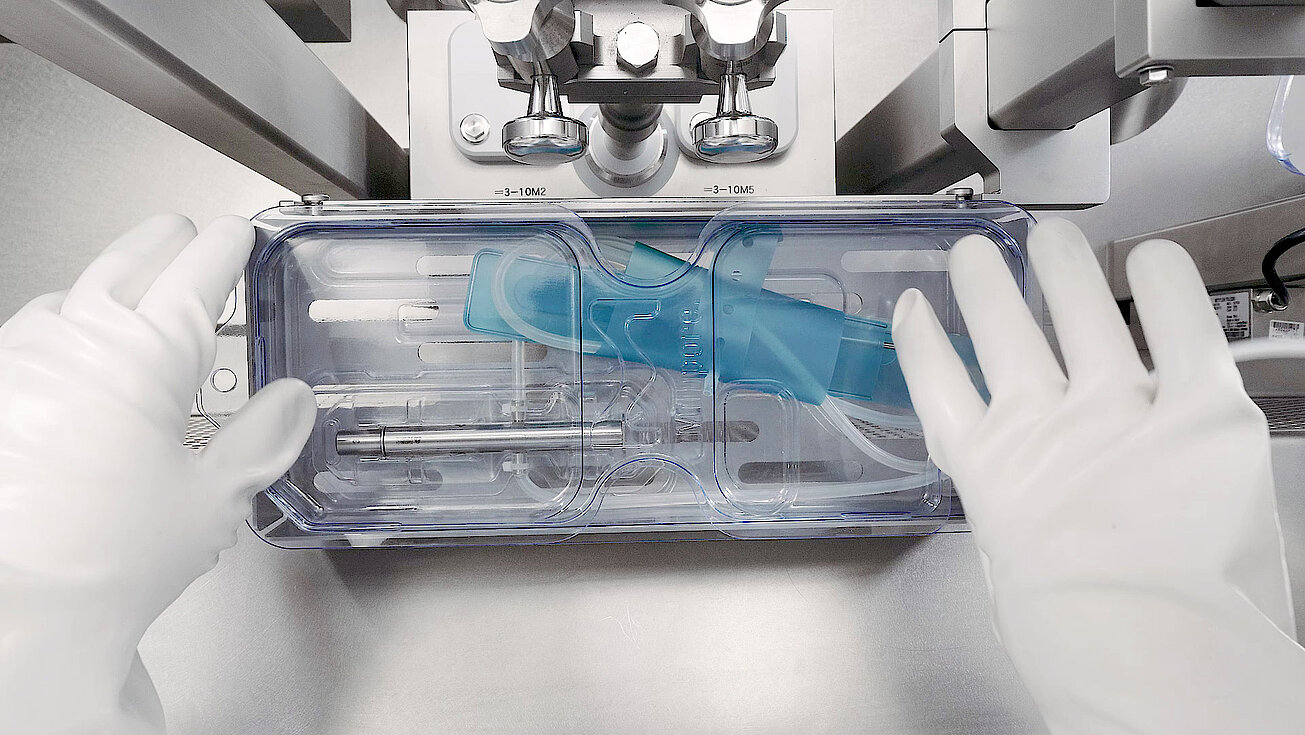

groninger single-use filling needles are available in different sizes, are compatible with groninger filling machines but can also be integrated by various machine vendors. Unlike multi-use needles, our single-use filling needles are provided cleaned and gamma irradiated, sterile and double packed. This eliminates the need for the end-user to perform any cleaning or sterilization of the needles. The needles are manufactured out of SST 316L/1.4435 according to DIN EN 10204 3.1. They have an inside and outside surface roughness of Ra 0.4 (except welding seams). With our best in-class single-use filling needle, we ensure optimum fill/finish results by establishing the highest quality standards.

Available in different sizes for a filling range from 0.1 ml – 100 ml

| Outer Diameter [OD] in mm | Inner Diameter [ID] in mm | Length in mm |

|---|---|---|

| 1.8 | 0.8 | 165 |

| 2.1 | 1.1 | 165 |

| 2.0 | 1.6 | 165 |

| 2.5 | 2.1 | 165 |

| 3.0 | 2.6 | 165 |

| 4.0 | 3.0 | 165 |

| 5.0 | 4.0 | 165 |

| 6.0 | 5.0 | 165 |

| 7.0 | 6.0 | 165 |

| 8.0 | 7.0 | 165 |

| 6.0 | 5.0 | 244 |

| 8.0 | 7.0 | 244 |

Benefits of Single-Use Filling Needles

- Eliminates the need for inline CIP/SIP

- Reduced CAPEX

- Reduced risk for cross contamination

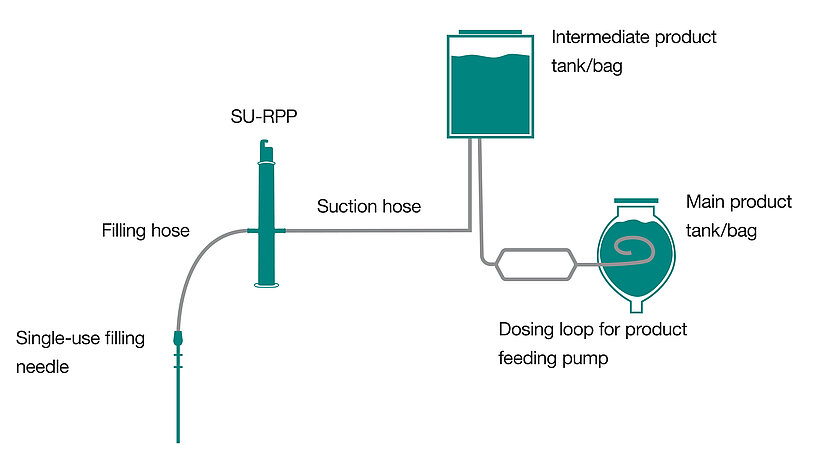

- Closed system/process

- Increased machine availability

Our single-use filling needles can be integrated into a final fill set manufactured by a single-use equipment supplier, or directly ordered and integrated by the end-user.

The needles are validated which includes the following:

Cleaning

- Validation and revalidation of microbiological reduction (EN ISO 11737)

- LAL Endotoxin Reduction (USP 85, ANSI/AAMI ST 72)

- Particulate load (USP 788)

- Cytotoxicity (EN ISO 10993)

- Bioburden (EN ISO 11737)

Sterility

- Validation and revalidation of gamma sterilization (EN ISO 11137)

- Validation on sterile barrier (EN ISO 11607, ASTM F 1980)

- Transport validation (EN ISO 11607, ISTA 2A)

- Accelerated storage-testing (EN ISO 11607, ASTM F 1980)

Storage

- Temperature range: 10–25 ºC

- Humidity: 30–60%

- Sterilization method: Gamma (min. 25 kGy)

- Max. dose: 50 kGy

- Working temperature range: 5–45 ºC

- UV protected, avoid direct solar irradiation

Shelf life

- 5 years after packaging (sterility claim for barrier system)

Certificate

- Declaration of Conformity (DOC)