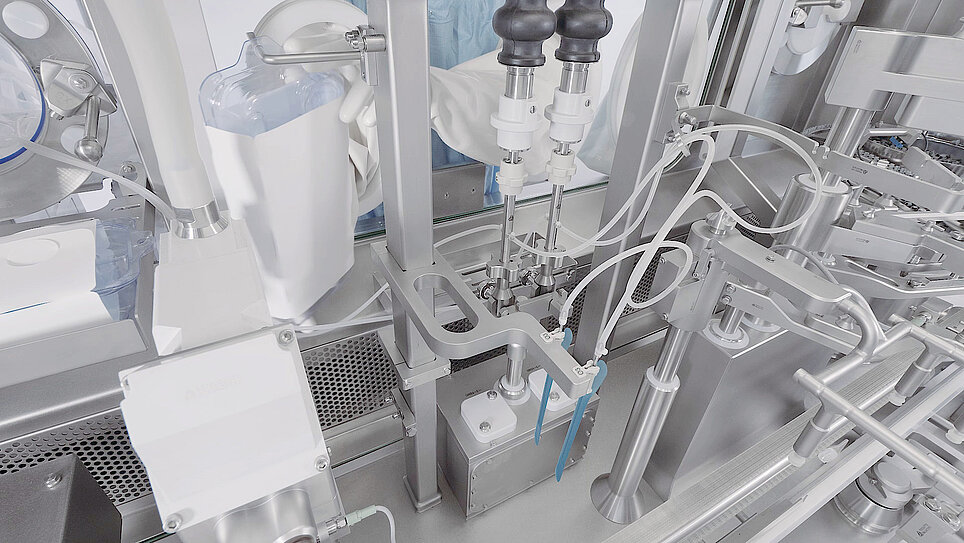

Single-Use Rotary Piston Pump

Ideally suited for difficult to fill products

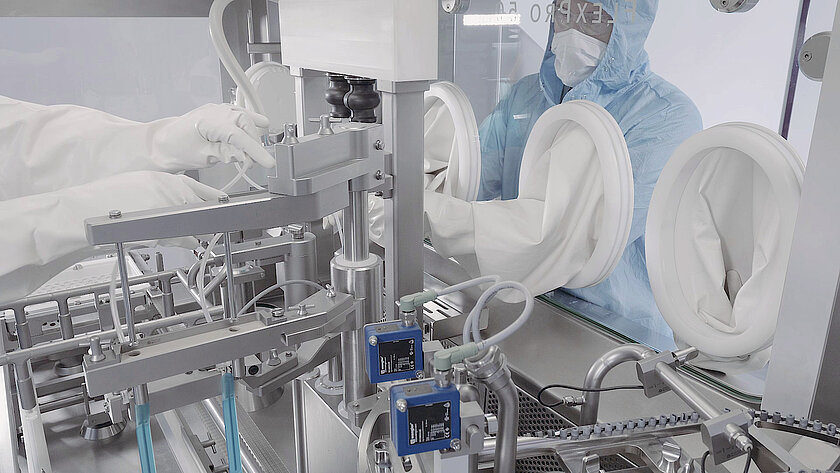

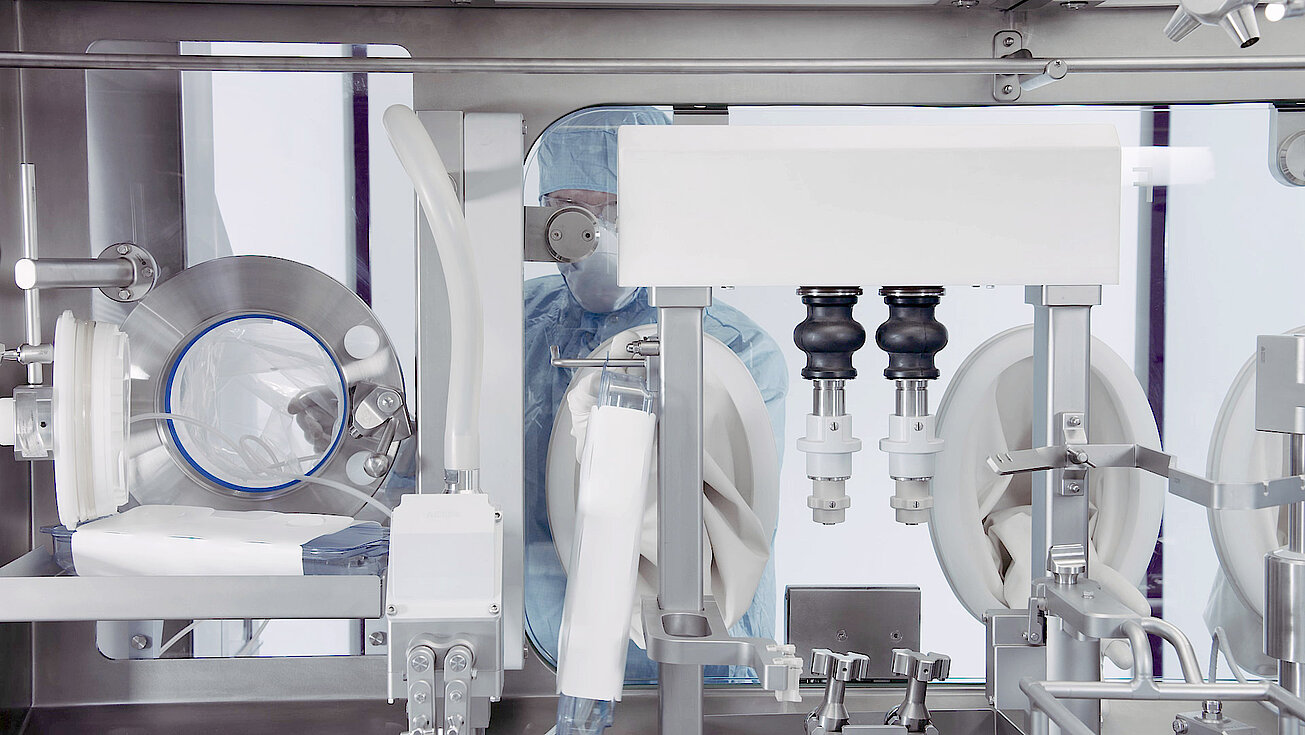

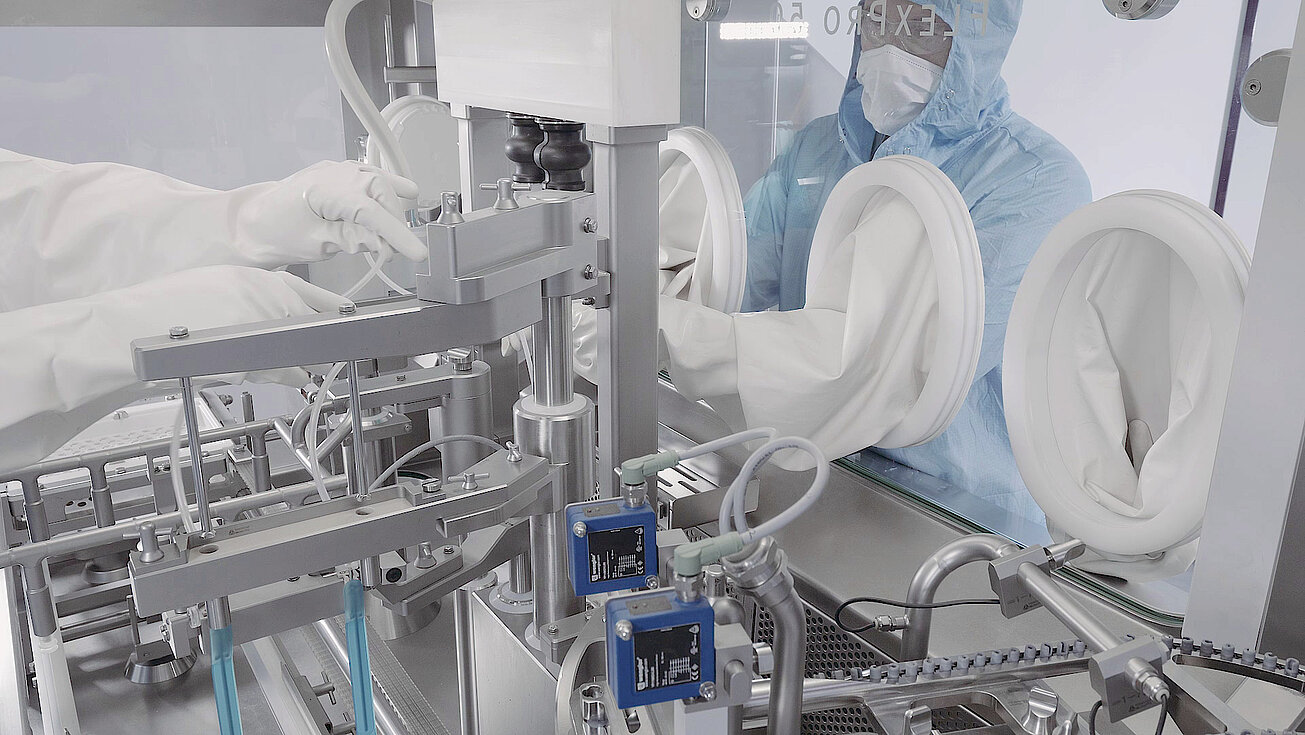

The pump can be used on all servo driven groninger filling machines, which are equipped with a rotary piston pump filling system by simply adding two adapters.

Ideally suited for filling products that are challenging to fill with a conventional peristaltic pump, this high-performance single-use rotary piston pump leverages groninger´s machine expertise and provides robust and accurate final fill dosage of highly viscous and oil-based products.

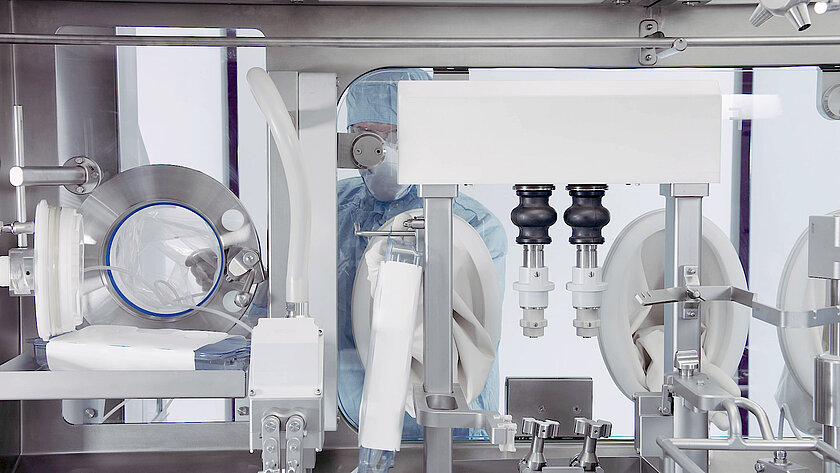

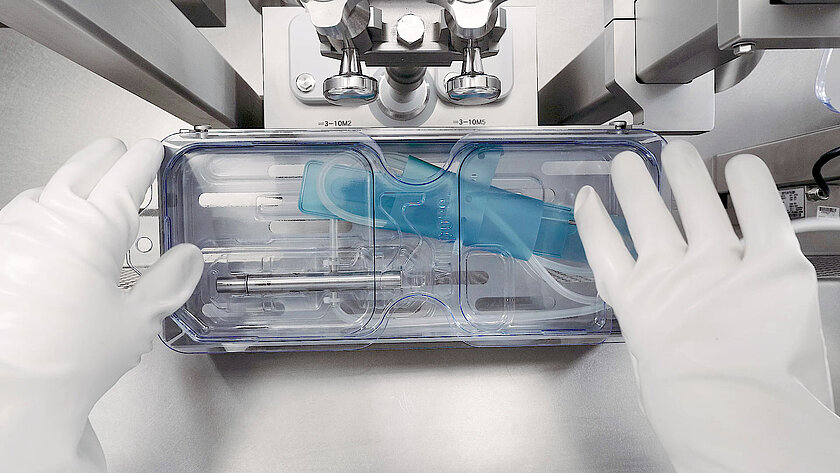

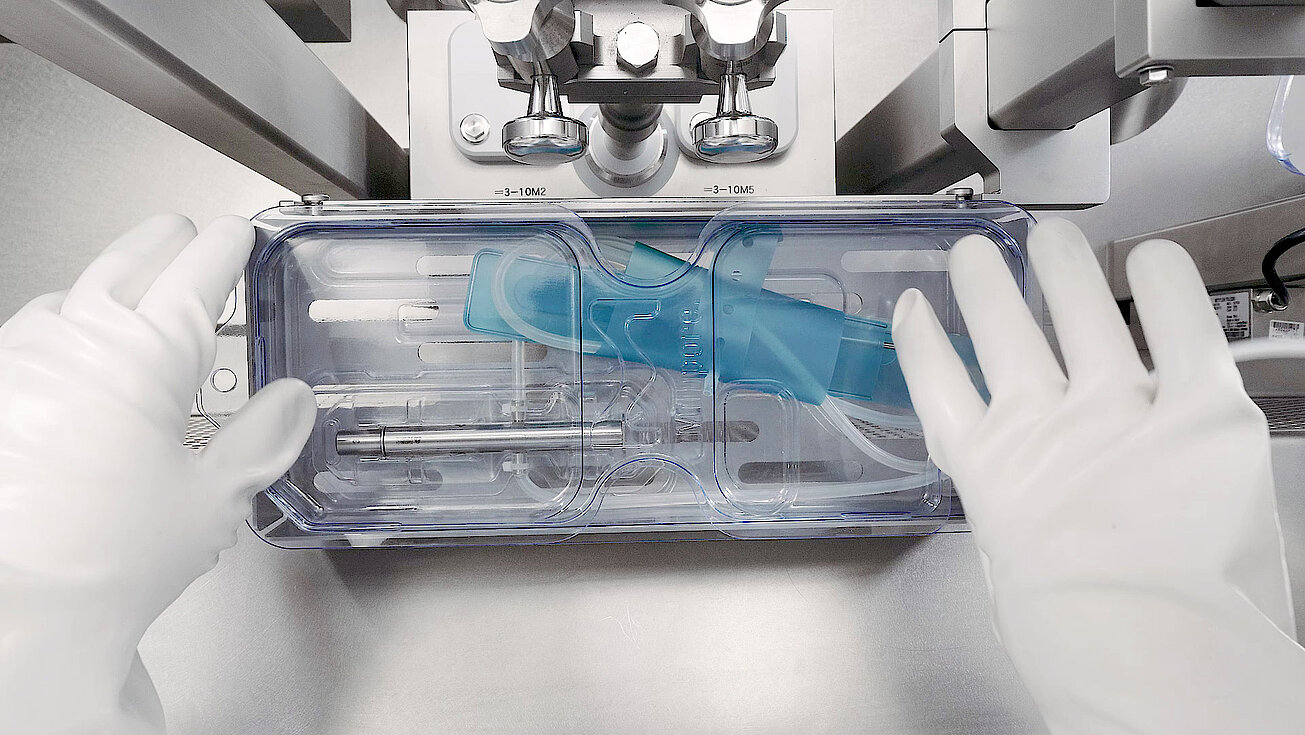

Our single-use pumps are ready-to-use products. This means they are getting provided cleaned, sterilized, and packed in blister packaging. This eliminates the need for the user to perform any cleaning or sterilization of the pumps before starting the batch.

Benefits of Single-Use Rotary Piston Pumps

- High performance dosing pump for challenging to fill products like viscous and oil-based solutions

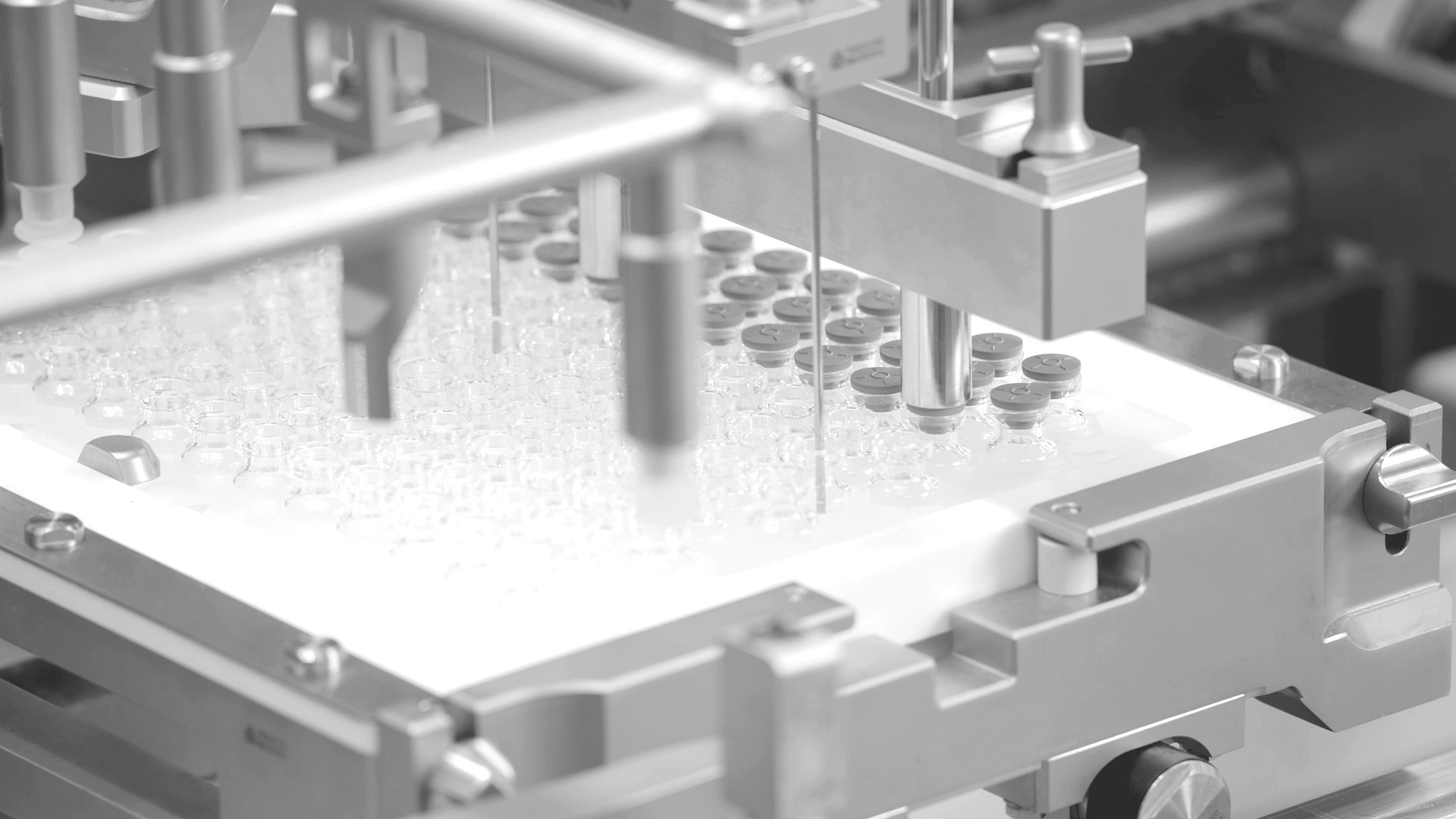

- High repeatability of dosing volume during the duration of the entire batch

- Sterile and ready to use, eliminating the need for cleaning, sterilization, and validation steps for the end user

- Possibility to run an existing (multi-use) rotary piston pump filling system in combination with a single-use fill path. No need to upgrade machine with peristaltic pump filling system (lower validation costs)

- Available as an integral part of the final fill set provided by Merck Millipore

Technical Specifications

- Available size: Diameter 10 mm

- Filling range: 0.1 – 2.25 ml

- Material: Every part in contact with the filling product is made of 316L/1.4435 according to DIN EN 10204 3.1, partial coated with chromium

- Surface quality: According to drawing: Ra ≤ 1.6 / Product contact parts: Ra ≤ 0.8

- Run time: 120,000 strokes

Filling accuracy comparable to multi-use rotary piston pump

| Filling range | Filling accuracy |

|---|---|

| > 0.2 - 0.5 ml | + - 1.40 % σrel |

| > 0.5 - 1.0 ml | + - 0,80 % σrel |

| > 1.0 - 2.25 ml | + - 0,50 % σrel |

The single-use rotary piston pumps are validated which includes the following

Cleaning

- According to effective validation documentation (referring to DIN EN ISO 11737-1; DIN EN ISO 10993; USP <1>; USP <61>; USP <85>; USP <87>; USP <788>) including bioburden, particle count; endotoxin content; cytotoxicity testing

Sterility:

- According to effective validation documentation (referring to DIN EN ISO 11137)

Type of packaging

- groninger single-use rotary piston pumps are ready-to-use products and are delivered gamma-sterilized and packed in double blister packaging

Storage

- 5 years after packaging (sterility claim for barrier system)

Certificate

- Declaration of Conformity (DOC)

Single-Use Filling Needles

Increase production while reducing risk and utility consumption